Aicher Werkzeugbau GesmbH

Contacts

Sabine Aicher

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

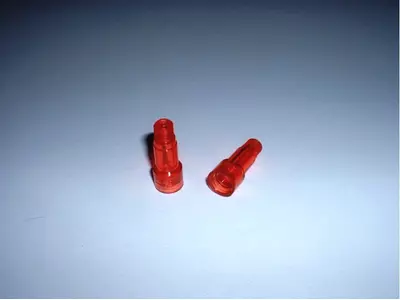

Parts (5)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 10000 | 1 - 700 | - | - | 1 - 140 | - | - |

Company description

AICHER TOOL has experience in the manufacture of injection molds for over 50 years. From micro molds up to a size of 450 x 600 mm, the portfolio ranges. This purpose we have in addition to the Stardardmaschinenausrüstung as milling center, Sodick wire EDM a WEILER CNC lathe and a JUNG-grinding machine as well as a HANSEN 500 E EDM machine available, with which we are also able to carry out or to work with most electrodes largest reductions. Design and construction We offer our customers, of course, the possibility of their data in all standard and many special formats (eg IGES, DWG, STEP, .....) to deliver to us. Customers still have an idea but no precise idea about the appearance of the article, we are happy to support in terms of design and our technical advice with our years of expertise. With our CAD system "SolidWorks" we are to create a lifelike image of your future product capable. PLASTIC TECHNOLOGY From the construction in our house to the finished molded part ..... You have the idea - we put you together with you to: Assembly - together develop the idea further - design - develop technical features and functionalities From Prototype to Production We use for creating photo-realistic views to the design of the tools the specially designed program "SolidWorks". To program the machine is us "Esprit" and "SolidCAM" is available. Both programs guarantee fast and accurate production. For inquiries and information, simply sat down with us. We also have experience in prototype construction in the area Rapid Prototyping Laser sintering Stereolithography Product optimization With our CAD software SolidWorks, we are able to create animations, which can detect possible conflicts in advance.This optimization of the product without prototype or consuming rework is possible.

Machines (11)

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Glass fibre-reinforced plastic

Industries

Precision engineering, mechatronics and optics

Medical technology

Special purpose machinery manufacturing

Mechanical engineering

Automotive and vehicle construction

Lighting industry

Furniture industry

Household appliance industry

Office machinery and supplies

Machine tool manufacturing

Electrical industry

Measurement and control technique, laboratory equipment

Air conditioning, refrigeration and ventilation industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.