Alkup Grup

Contacts

Dushan Plushkoski

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (1)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 500000 | max. 1000 | - | - | max. 150 | - | - |

Automatic turning (bar) | 1 - 500000 | max. 800 | - | - | 10 - 50 | - | - |

Full-range turning (including milling) | 1 - 500000 | 1 - 300 | - | - | 1 - 150 | - | - |

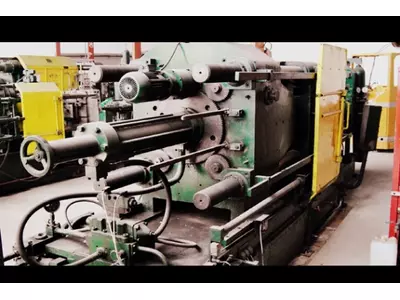

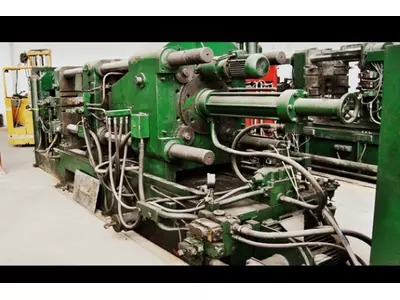

Company description

Established in 2008 in Skopje, North Macedonia, Alkup Grup began as a small family-driven business specializing in aluminium die-casting. Our initial focus was on delivering high-quality aluminium components for the automotive industry, leveraging our expertise in precision manufacturing. Over the years, we expanded our capabilities to meet the growing demands of our clients. What started as a die-casting operation gradually evolved into a full-service manufacturing hub. We introduced CNC machining, automatic sawing, powder coating, vibratory polishing, and sandblasting, among other processes. Each new capability was a response to the needs of our clients and the ever-changing landscape of modern manufacturing. Today, Alkup Grup is a trusted partner across Europe, known for our commitment to quality, innovation, and sustainability. Our journey from a small die-casting workshop to a multi-process manufacturing leader has been shaped by our dedication to excellence and our ability to adapt to new challenges. Our facility in Struga combines traditional craftsmanship with modern technology. We have invested in machinery, quality control systems, and sustainable practices, including our rooftop solar installation that powers our operations with renewable energy. At Alkup Grup, we believe in the power of collaboration. Our team of skilled professionals works closely with clients to develop innovative solutions that meet their unique needs. Whether it's a complex automotive component or a precision part for renewable energy systems, we are here to deliver what you need in the most efficient way we can.

Copmany images

Materials

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Industries

Apparatus engineering

Automotive and vehicle construction

Fittings engineering

Furniture industry

Household appliance industry

Mechanical engineering

Military engineering

Electrical industry

Automation and control engineering

Precision engineering, mechatronics and optics

Aerospace and aviation industry

Air conditioning, refrigeration and ventilation industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.