Andreas Mull Werkzeugbau und Zerspanungstechnik GmbH

Contacts

Felix Mull

Design

Phone:

E-Mail:

Competencies

Parts (9)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 10000 | 10 - 1295 | - | - | 10 - 635 | max. 60 | - |

Full-range turning (including milling) | 10 - 1000 | 10 - 450 | - | - | 10 - 300 | max. 60 | - |

Company description

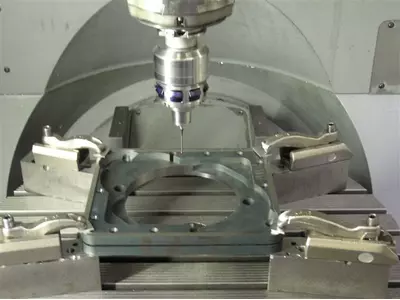

Tool making and machining Mull Tool Making and Machining GmbH – Your qualified business partner for series production, unit production and prototype production! We manufacture units on modern 5 axis CNC machining centres with the material of your choice, for example steel (e.g. St52, 1.4305, 16MnCr5 or C45), titan (e.g. Ti6Al4V), aluminium (e.g. AlMgSi, AlMg3, AlMgCuPb or AlZnMgCu1,5) and plastics (e.g. POM, PA, PA6.6 GF30 or PTFE). Magnesium manufacturing Furthermore, we offer our customers, to take over complete manufacturing processes like machining magnesium parts from solid metal (e.g. AZ31B) including the proximate surface treatment. We also carry out the mechanical processing of series parts from magnesium pressure cast - e.g. AZ91 Reliable quality Because of our efficient production processes we are able to provide competitive prices and a constant high grade. Mull Tool Making and Machining has modern machinery and the required know-how to produce all parts exactly meeting to your needs. Of course we obey all relevant norms and apply our certified quality management ISO 9001:2008 since 2002. On our 1200qm production area you will find all fields of manufacturing close together. That way we are able to deal with your orders promptly and efficiently. Our Services • Series production • Prototype production • Unit produktion • Magnesium machining • Magnesium chipping • Titanium machining • Pressure casting • further casting-methods • CNC-turning • CNC-milling • CNC-electrical discharging • Tooling

Machines (30)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Plastics/synthetic materials

Thermoplastics

Thermosets

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Natural Fibre Composites (NFC)

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Cast metals

Cast steel

Cast iron

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Silicium

Industries

Automotive and vehicle construction

Aerospace and aviation industry

Packaging industry

Paper and printing machinery industry

Electrical industry

Apparatus engineering

Power generation and transmission industry

Boiler, container and tank construction

Chemical industry

Air conditioning, refrigeration and ventilation industry

Building, agricultural and forestry machinery manufacturing

Mining and tunnel engineering

Automation and control engineering

Construction and architectural supplies

Fittings engineering

Military engineering

Special purpose machinery manufacturing

Machine tool manufacturing

Drive and gear engineering

Precision engineering, mechatronics and optics

Mechanical engineering

Medical technology

Hydraulic and pneumatic industry

Plant engineering and construction

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.