Buchert + Feil GmbH

Contacts

Ronny Feil

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (2)

Technologies

Surface Treatment

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Anodizing | 1 - 10000 | 5 - 800 | 5 - 800 | 5 - 800 | - | max. 50 | - |

Pickling | 1 - 10000 | 5 - 800 | 5 - 800 | 5 - 800 | - | max. 50 | - |

Blacking | 1 - 10000 | 5 - 500 | 5 - 500 | 5 - 500 | - | max. 50 | - |

Chromatizing | 1 - 10000 | 5 - 800 | 5 - 800 | 5 - 800 | - | max. 50 | - |

Electroplating | 1 - 1000 | 1 - 100 | 1 - 100 | 1 - 100 | - | max. 2 | - |

Parts cleaning/degreasing | 1 - 10000 | 1 - 800 | 1 - 800 | 1 - 800 | - | max. 50 | - |

Sand blasting | 1 - 10000 | 5 - 800 | 5 - 800 | 5 - 800 | - | max. 50 | - |

Spray-painting | 1 - 1000 | 5 - 1200 | 5 - 1200 | 5 - 1200 | - | max. 50 | - |

Company description

Your specialist for high-quality surface finishing, assembly of complex components and CNC manufacturing in compliance with the highest quality standards. Making a difference for our customers — that is the vision of Buchert + Feil. That is why we incorporate our knowledge and experience into each of our production areas. Comprehensive and individual support before, during and after project completion, combined with timely and cost-oriented project management, create transparency and planning security. Peter Buchert and Ronny Feil, who enjoy an excellent reputation in the CNC industry, are also closely linked to the region and committed to absolute quality standards. Her customers include high-performance optics and measurement technology companies. While the fate of “Made in Eisfeld” has often been steered by international players in the past, Buchert+Feil, a company from the region is now taking over Noblex GmbH to write a new chapter in the “Quality from Thuringia” success story. Buchert + Feil combine the experience of rock-solid, proven technical processes with the advantages of the latest technologies. The company focuses entirely on digitization and optimization of production, with a focus on manufacturing, surface finishing and assembly of complex components at the Eisfeld site. BENEFITS Machining — milling, turning, grinding, eroding (molybdenum, 4th axis), HM/ceramic, gearing and subsequent quality assurance at the highest level. Surface finishing — We offer you a wide range of surface treatment processes: anodizing (including hard anodizing), burnishing, SurTec 650, gilding, painting, blasting, lasering, passivation, gilding and washing. Assembly — professional assembly of small and large components as well as mechanical, optomechanical and electromechanical components. Cleanroom parts cleaning ISO class 5 — For particularly demanding applications and sensitive parts.

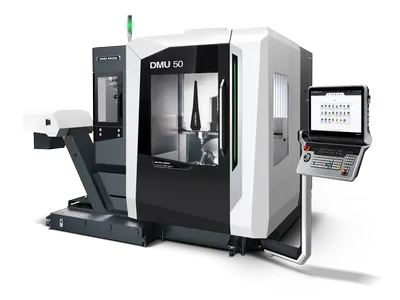

Machines (8)

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Cast metals

Cast steel

Cast iron

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Industries

Hydraulic and pneumatic industry

Medical technology

Machine tool manufacturing

Plant engineering and construction

Automotive and vehicle construction

Drive and gear engineering

Automation and control engineering

Precision engineering, mechatronics and optics

Aerospace and aviation industry

Mechanical engineering

Measurement and control technique, laboratory equipment

Military engineering

Clean room technology

Shipbuilding industry

Special purpose machinery manufacturing

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.