Clausnitzer & Mitte Erodierbetrieb GmbH

Contacts

Philipp Schädlich

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (4)

Technologies

Water jet cutting

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Water jet cutting 2D | 1 - 2000 | max. 2500 | max. 1500 | - | - | - | max. 110 |

Company description

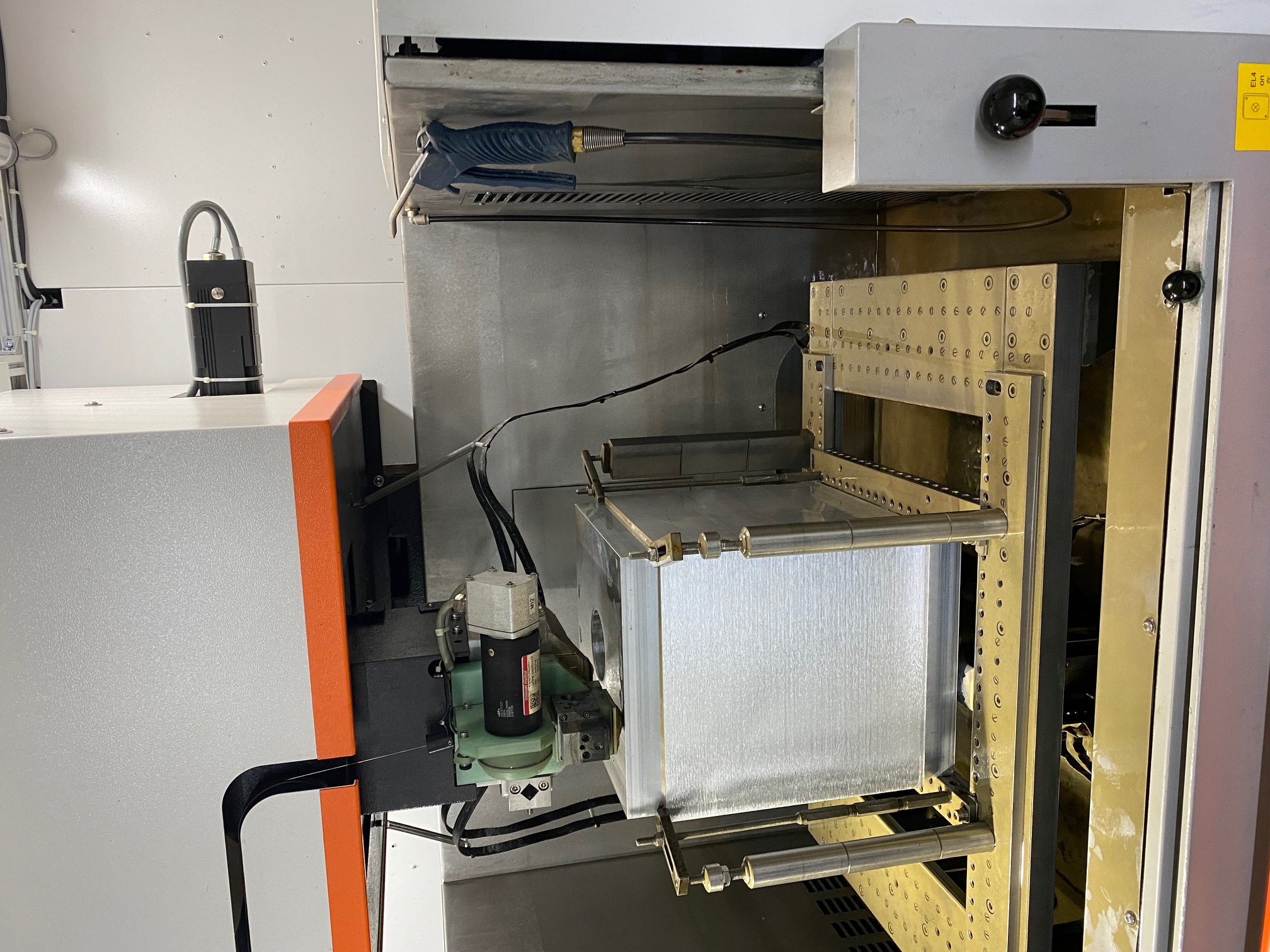

In addition to carrying out contract work (wire, sink, start hole eroding, 3D milling, waterjet cutting, surface grinding), it is possible to completely manufacture active tool parts (including heat treatment).

Machines (7)

Materials

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Non-metal inorganic materials

Ceramics

Glass

Concrete

Cast minerals

Graphite

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Silicium

Cast metals

Cast steel

Cast iron

Natural materials

Wood/timber

Rock

Industries

Mechanical engineering

Machine tool manufacturing

Special purpose machinery manufacturing

Plant engineering and construction

Automotive and vehicle construction

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.