Demark sp. z o.o.

Contacts

Agnieszka Kwiatkowska

Marketing and Sales

Phone:

E-Mail:

Competencies

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 99999998 | max. 99999998 | max. 99999998 | - | - | - | max. 99999998 |

Bending / folding | 1 - 99999998 | max. 99999998 | - | - | - | - | max. 99999998 |

Company description

Our company, present in the market for over 30 years, specializes in providing stainless steel, heat-resistant steel, as well as nickel and titanium alloys. We offer a wide range of products and services tailored to the specific needs of large investments and unusual orders. Our portfolio includes, among others, hot and cold-rolled sheets, seamless and welded pipes, drawn and rolled bars, as well as a wide range of profiles and fittings. We also specialize in Duplex, Super Duplex, and Lean Duplex steels. Chemical plants, petrochemical plants, refineries, power plants, shipyards, and construction and assembly companies are just some of the industries we serve, providing them with the highest quality products. Discover our range of specialized steel processing services. Choose below to learn more. We love challenges. Handling orders in unusual dimensions and grades is our standard. Over 30 years of experience in key industries for the economy, cooperation only with recognized manufacturers and steel warehouses from around the world, as well as the guarantee of timely deliveries and professional technical support - these are the foundations of our market trust. We focus on quality. We collaborate with 185 verified steel manufacturers. Our products and services are a guarantee of the highest quality, confirmed by ongoing cooperation with leading industries in Poland and Europe. We operate an advanced machine park equipped with 10 kW laser cutters. Our workstations enable cutting large-format sheets with diverse specifications. Material thickness capabilities Stainless and carbon steel up to 30 mm Aluminum up to 30 mm Brass up to 15 mm Copper up to 12 mm We offer professional press brake bending, enabling precise forming of metal components in a wide range of shapes. We use the modern TruBend 5320 press brake from Trumpf, which features a pressing force of 3200 kN and a maximum bending length of up to 4420 mm. This ensures top quality and repeatability.

Machines (3)

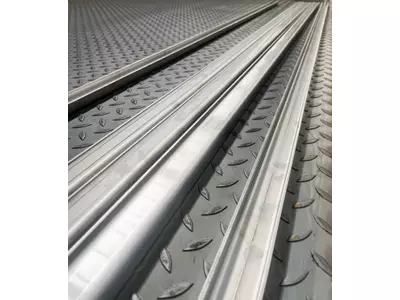

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Industries

Automotive and vehicle construction

Chemical industry

Railway and rail vehicles industry

Electrical industry

Power generation and transmission industry

Air conditioning, refrigeration and ventilation industry

Boiler, container and tank construction

Shipbuilding industry

Special purpose machinery manufacturing

Machine tool manufacturing

Apparatus engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.