Edil-Komszer Kft

Contacts

János Schneider

Production

Phone:

E-Mail:

Competencies

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 999999 | 1 - 3000 | 1 - 1500 | - | - | - | 1 - 15 |

Bending / folding | 1 - 999999 | 1 - 2500 | - | - | - | - | 1 - 8 |

Plasma fusion cutting | 1 - 99999 | 1 - 3000 | 1 - 1500 | - | - | max. 200 | 1 - 5 |

Plate rolling / bending | 1 - 999999 | - | 1 - 2000 | - | - | - | 1 - 6 |

Plate straightening | 1 - 99999 | - | 1 - 2000 | - | - | - | 1 - 6 |

Shearing (rectangular blank/strip) | 1 - 999999 | - | - | - | - | - | 1 - 6 |

Company description

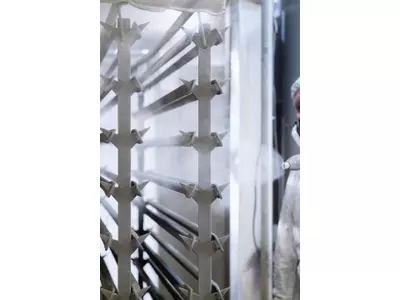

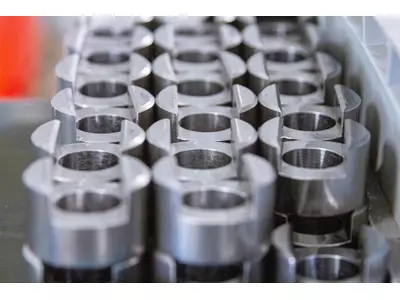

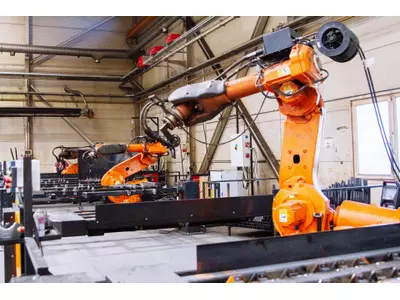

Company profile — Edil-komszer Kft. EDIL-Komszer Kft. was founded in 2001 with the aim of producing high-quality metal processing products for the European market. Our expertise and modern technological equipment make it possible to produce quality products from mild steel, aluminum and stainless steel. During our production processes, we place particular emphasis on the careful selection of raw materials and strict compliance with the associated technological regulations. Our customers include companies from the mechanical engineering, food and construction industries. Our machinery is suitable both for series production and for custom-made products. The focus is always on on-time production in the required quality. Our team of qualified welders, sheet metal processing and machining engineers works with state-of-the-art machines on a production area of 10,000 m² in accordance with European standards to ensure that our products meet the highest quality requirements. Our machinery (selection): • CAD programs • CNC press brakes • Hydraulic and eccentric presses • Automatic sheet and bar material cuts • Machining equipment • Welding robots and welding machines for all welding processes • Blasting systems • powder coating plant Based on customer requirements, we develop manufacturing technology and material quality, optimize costs and, if necessary, take over the procurement of materials and the coordination of delivery. Through our long-standing partnerships, we can also ensure the necessary surface treatment — from galvanization to various mechanical processes — to guarantee the required surface quality.

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Industries

Lighting industry

Furniture industry

Mechanical engineering

Air conditioning, refrigeration and ventilation industry

Electrical industry

Building, agricultural and forestry machinery manufacturing

Construction and architectural supplies

Plant engineering and construction

Machine tool manufacturing

Special purpose machinery manufacturing

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.