FBR Facondrehteile

Contacts

Rainer Schenk

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 5 - 10000 | 10 - 1000 | - | - | 1 - 420 | - | - |

Automatic turning (bar) | 2 - 50000 | 5 - 800 | - | - | 10 - 100 | - | - |

Full-range turning (including milling) | 5 - 20000 | 10 - 500 | - | - | 10 - 420 | - | - |

Hard turning | 5 - 15000 | 10 - 500 | - | - | 10 - 420 | - | - |

Company description

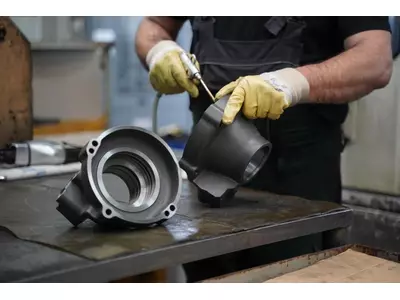

Since 1981, we have been manufacturing precision turned and milled parts at our site in Kirchhaslach (Unterallgäu) for well-known customers in mechanical engineering, drive and agricultural technology, valve and vehicle manufacturing as well as the automotive industry. As a medium-sized family company with over 40 years of experience, we combine modern CNC technology with established manufacturing expertise and see ourselves as a system partner for ready-to-install components and assemblies. fbr-gmbh.de +2 fbr-gmbh.de +2 Our machinery includes horizontal and vertical CNC lathes with a maximum turning diameter of approx. 400 mm and a processing length of up to 1,000 mm as well as modern machining centers and 5-axis milling centers for complex contours. In this way, we produce individual components from individual pieces to series in small and medium-sized series — including all necessary preliminary and post-processing such as sawing, grinding, heat treatment, surface treatment and assembly into ready-to-install components. fbr-gmbh.de +2 fbr-gmbh.de +2 A particular unique selling point is our ability to coat components with molybdenum — a process that is only offered by a few companies in Germany. In addition, with the patented “Safety Lock” hydromechanical locking cylinder, we are developing and manufacturing our own product line for safety-critical applications in load, transport and load securing. As a result, in addition to classic drawing parts, we can also supply complete hydraulic components and functional assemblies from a single source. fbr-gmbh.de +2 fbr-gmbh.de +2 Quality and sustainability are firmly anchored in our corporate philosophy: Certified quality management in accordance with DIN EN ISO 9001 and environmental management in accordance with EMAS/ ISO 14001 form the basis for stable processes. Supported by cutting-edge 3D measurement technology from ZEISS, we can also reliably test and document large components with dimensions of up to 1,200 x 1,800 x 800 mm. Bayern International +3 fbr-gmbh.de +3 fbr-gmbh.de +3 For our customers, this means: high process reliability, short response times and a reliable partner who integrates technical advice, manufacturing and logistics. Whether it's a prototype, ready-to-install series component or safety-relevant locking cylinder — FBR Facondrehteile stands for precise, punctual and economical solutions “made in Bavaria”.

Machines (2)

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Cast metals

Cast steel

Cast iron

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Industries

Mechanical engineering

Hydraulic and pneumatic industry

Railway and rail vehicles industry

Building, agricultural and forestry machinery manufacturing

Automotive and vehicle construction

Drive and gear engineering

Shipbuilding industry

Military engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.