Frumolde Tooling Lda

Contacts

Competencies

Parts (3)

Technologies

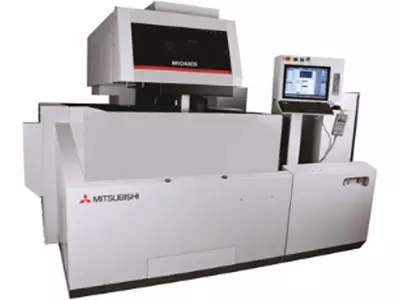

Etching and Spark Erosion

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Spark erosion wire cutting | 2 - 4 | 50 - 1600 | 50 - 800 | 50 - 500 | - | max. 1800 | - |

Spark erosion countersinking | 20 - 1000 | 10 - 1200 | 10 - 1000 | 10 - 450 | - | max. 3000 | - |

Company description

Frumolde has 35 years of experience in the injection mold industry, with a track record defined by quality and precision in the design, manufacturing, and maintenance of molds. In recent years, the company has also specialized in series machining of steel parts, using state-of-the-art technology such as 5-axis GROB CNC machines, among others, to ensure maximum precision and efficiency. Frumolde continues to invest in innovation to meet the demands of the market and its customers.

Machines (15)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Cast metals

Cast steel

Cast iron

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Non-metal inorganic materials

Graphite

Industries

Aerospace and aviation industry

Railway and rail vehicles industry

Military engineering

Machine tool manufacturing

Measurement and control technique, laboratory equipment

Mechanical engineering

Building, agricultural and forestry machinery manufacturing

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.