Heinrich Greve Maschinen- u. Apparatebau GmbH & Co. KG

Contacts

Elias Rosentreter

Phone:

E-Mail:

Leon Koring

Marketing and Sales

Phone:

E-Mail:

Jörg Kirchhoff

Purchasing / Material management

Phone:

E-Mail:

Jörg Grote

Technical management

Phone:

E-Mail:

Competencies

Parts (12)

Technologies

Welded constructions / Structural Steelwork

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Welded constructions (weldments) | - | 1 - 3000 | 1 - 3000 | 1 - 3000 | - | max. 5000 | - |

Machine frames / bases / racks | - | 1 - 3000 | 1 - 3000 | 1 - 3000 | - | max. 5000 | - |

Beam prefabrication | - | 1 - 3000 | 1 - 3000 | 1 - 3000 | - | max. 5000 | - |

Company description

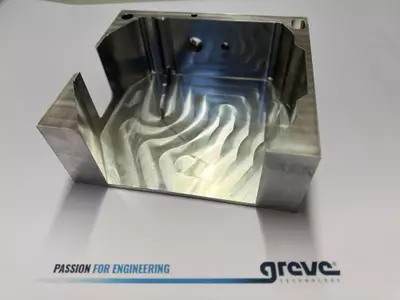

PASSION FOR ENGINEERING - since more than 50 years Heinrich Greve GmbH, based in Lübbecke, has been synonymous with innovative solutions in manufacturing technology since 1966. What began as a pure contract manufacturer has developed over the decades into a sought-after manufacturer of high-quality production units and technical rollers. Today, we offer a broad and flexibly adaptable range of manufacturing services – precise, on time, and customer-oriented. COMPETENCE THROUGH EXPERIENCE With over 50 years of industry experience, we are one of the established specialists in packaging technology. Our components and assemblies are used in numerous well-known machines – often unnoticed, but crucial to their function. In recent years, we have deliberately expanded our focus: we are increasingly specialising in the manufacture of rollers, large components and complex welded assemblies. Thanks to modern machinery and qualified specialists, we are able to produce even the most demanding components with the highest precision. As a second-generation owner-managed family business, we place particular emphasis on quality, reliability, and partnership-based cooperation. Our dedicated team provides you with expert support in implementing your individual requirements – from the initial idea to the finished solution.

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Milling

Turning

Welded constructions (weldments)

Full-range turning (including milling)

Inert gas shielded arc welding (MIG/MAG)

Laser cutting 2D

Plate rolling / bending

Spinning

HSC milling

Engraver milling

Ultrasonic milling

Deep-hole drilling

Form milling (3 D)

Cylindrical gear / spur gear

Drilling / threading / tapping

11

5

4

4

3

1

1

1

1

1

1

1

1

1

1

Machines (6)

Copmany images

Materials

Plastics/synthetic materials

Thermoplastics

Thermosets

Elastomers

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Cast metals

Cast steel

Cast iron

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Industries

Special purpose machinery manufacturing

Drive and gear engineering

Building, agricultural and forestry machinery manufacturing

Medical technology

Apparatus engineering

Machine tool manufacturing

Automotive and vehicle construction

Mechanical engineering

Paper and printing machinery industry

Plant engineering and construction

Automation and control engineering

Packaging industry

Hydraulic and pneumatic industry

Railway and rail vehicles industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.