Helmut Schlachter GmbH

Contacts

Utku Kanar

Phone:

E-Mail:

Felix Löffler

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (5)

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 500 | 15 - 3000 | 15 - 1500 | - | - | - | 0.5 - 25 |

Bending / folding | 1 - 1000 | max. 3000 | - | - | - | - | max. 8 |

Punching / nibbling | 1 - 500 | max. 99999998 | max. 99999998 | - | - | - | max. 2 |

Company description

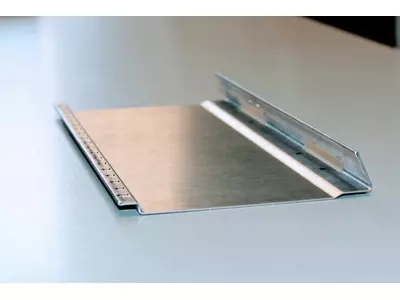

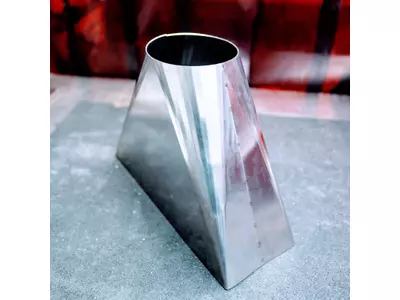

Helmut Schlachter GmbH, based in Karlsruhe, Germany, is a family-owned metalworking company now in its fifth generation. The company’s origins date back to 1896, with the current GmbH established in 1981. As a full-service manufacturing partner, Helmut Schlachter GmbH covers the entire value chain – from technical consulting and design support to manufacturing, finishing, and logistics. The company specializes in custom-made components and assemblies made of steel, stainless steel, and aluminum. Core capabilities: Laser cutting (up to 1500 × 3000 mm) Press brake bending up to 3000 mm Welded assemblies (MIG/MAG, TIG, laser welding) Mechanical finishing (drilling, tapping, grinding) Surface finishing and external coatings Assembly and small to medium batch production Materials processed: Steel up to 25 mm Stainless steel up to 20 mm Aluminum up to 12 mm Helmut Schlachter GmbH serves customers in mechanical engineering, electrical engineering, automotive and vehicle construction, metal and plant engineering, packaging, food processing, as well as design and special-purpose applications. The company operates according to DIN EN ISO 9001:2015 and is certified to EN 1090 (CE). A modern machine park, high vertical integration, and reliable delivery times – including for small batch sizes – characterize Helmut Schlachter GmbH as a dependable manufacturing partner.

Machines (3)

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Industries

Plant engineering and construction

Machine tool manufacturing

Packaging industry

Special purpose machinery manufacturing

Air conditioning, refrigeration and ventilation industry

Mechanical engineering

Medical technology

Paper and printing machinery industry

Furniture industry

Apparatus engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.