Hydravlon-1 Ltd.

Contacts

Boris Zhelev

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

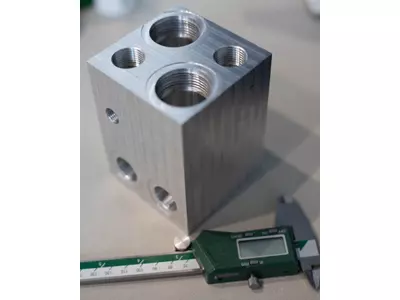

Parts (2)

Technologies

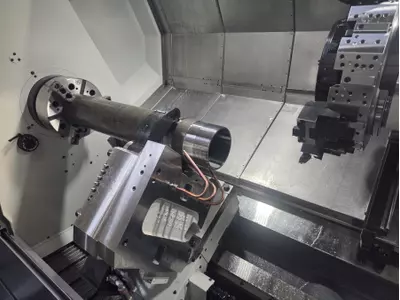

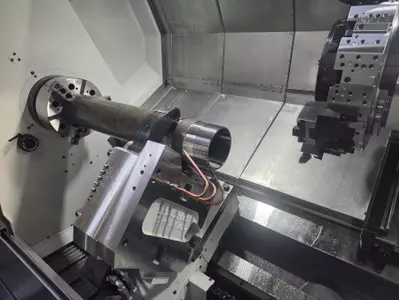

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 1000 | max. 99999998 | - | - | max. 99999998 | - | - |

Full-range turning (including milling) | 2 - 10000 | 1 - 3200 | - | - | 1 - 550 | - | - |

Shaft machining | 2 - 10000 | 1 - 3200 | - | - | 1 - 550 | max. 5000 | - |

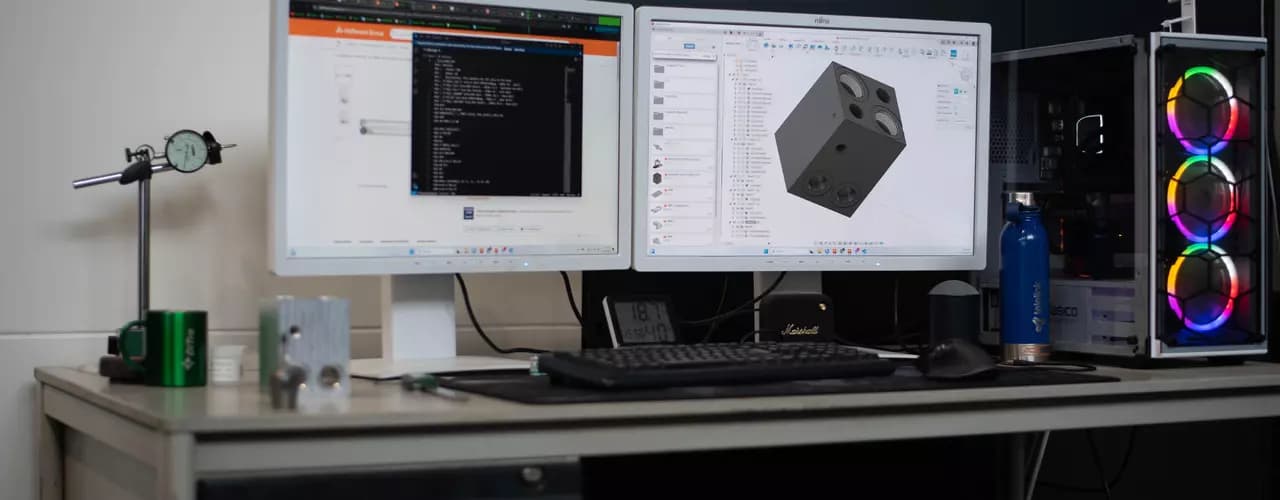

Company description

Hidravlon-1 is a long-standing partner of all shipbuilding and ship repair companies in Bulgaria mainly in the field of hydraulic systems. Since 2023, the company's team and machine park have been expanding significantly, with the aim of increasing the scope of engineering and manufacturing services. We have at our disposal a 3-axis M1 VMC from DMG Mori, and a last generation 4-axis turning center from our Spanish partner CMZ, model TD-30Y-3200. It is equipped with 12000 rpm live tools for milling operations and a Y-axis on the turret and is capable of processing diameters up to 550 mm and workpiece lengths up to 3200mm, positioning us well for the energy, mining and marine industries. And with plenty of space to grow, we are more than prepared to address any specific production requirements You might have. The company specializes in providing customized solutions for design, supply of materials and production of parts from ferrous and non-ferrous metals, engineering plastics, etc., with the team's main experience being in the production of hydraulic components and spare parts for them. In addition to manufacturing solutions Hydravlon-1 Ltd. can also offer: • repairs and re-manufacturing of hydraulic equipment • production of high-pressure industrial hoses • hydraulic system components and spares in stock • welding services (TIG, MIG/MAG, Argon) • finishing treatments • assembly of nodes or individual components Over 3 decades after our founding, our ambition is to continue to be the most reliable partner for hydraulic maintenance and production of components in the region. We have a team capable of assisting partners from the design phase, through manufacturing and optimization, to finishing and final assembly of nodes. We practice uncompromising quality control and high work rates, because we know that trust is the most valuable asset. Our team is available to answer all of your questions!

Machines (5)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Plastics/synthetic materials

Thermoplastics

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Industries

Power generation and transmission industry

Military engineering

Mining and tunnel engineering

Packaging industry

Aerospace and aviation industry

Building, agricultural and forestry machinery manufacturing

Electrical industry

Railway and rail vehicles industry

Special purpose machinery manufacturing

Shipbuilding industry

Mechanical engineering

Machine tool manufacturing

Hydraulic and pneumatic industry

Drive and gear engineering

Automotive and vehicle construction

Automation and control engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.