LOLO equipment SIA

Contacts

Nils Plētiens

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (4)

Technologies

Measuring & Testing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Measuring / testing | - | 0.5 - 500 | 0.5 - 500 | 0.5 - 500 | 1 - 500 | max. 200 | - |

Company description

We are a turnkey solution provider, specializing in transforming our clients’ ideas into finished products, precision components, or even complete manufacturing machinery. Our capabilities cover the entire product development cycle: Engineering & Design – from concept to technical drawings Prototype Development & Testing CNC Manufacturing – including complex and high-precision parts Custom Machinery Design & Fabrication Automation & Programming – including PLC and CNC systems Production Optimization – including part redesign for cost-effective manufacturing Electrical Integration – wiring, control systems, and panel building We work across a wide range of materials, including plastics, aluminum, copper, stainless steels, titanium, and exotic alloys like tantalum and Hardox. Whether you need a single precision part, a functional prototype, or a fully automated production system, we provide a complete and reliable manufacturing solution.

Machines (1)

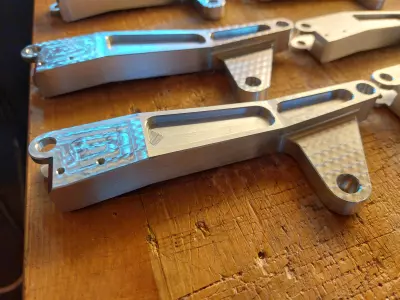

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Precious metals

Other precious metals

Industries

Construction and architectural supplies

Electrical industry

Special purpose machinery manufacturing

Aerospace and aviation industry

Hydraulic and pneumatic industry

Precision engineering, mechatronics and optics

Mechanical engineering

Machine tool manufacturing

Automation and control engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.