Metallbau Hoese GmbH

Contacts

Christian Schaumann

Technical management

Phone:

E-Mail:

Competencies

Technologies

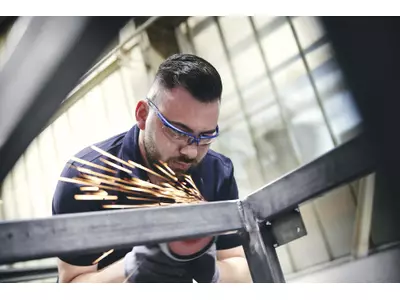

Welding

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Inert gas shielded arc welding (MIG/MAG) | 1 - 10000 | 100 - 3000 | 50 - 1500 | 50 - 1800 | 200 - 3000 | 1 - 3000 | 1 - 15 |

Inert gas shielded arc welding (TIG) | 1 - 10000 | 100 - 3000 | 50 - 1500 | 50 - 1800 | 200 - 3000 | 1 - 3000 | 1 - 8 |

Laser-beam welding | 1 - 100000 | 10 - 3000 | 10 - 600 | 10 - 600 | max. 600 | max. 250 | - |

Robot welding | 1 - 10000 | 50 - 1600 | 50 - 1250 | 50 - 600 | - | max. 400 | - |

Spot welding | 1 - 5000 | - | - | - | - | - | 1 - 3 |

Company description

Since 1979, Metallbau Höse GmbH has stood for the highest precision and quality in sheet metal processing. As a family-owned company based in Biedenkopf-Wallau, we offer a comprehensive range of services, including laser cutting, punching, welding, deburring, bending, and complete assembly of components. Our state-of-the-art machinery, equipped with TRUMPF technology and partially fully automated, enables us to deliver customized solutions for our clients. Our core competencies include: Laser cutting: Burr-free cutting results for the highest demands. Bending: Precise production starting from batch size 1. Welding: Clean weld seams in steel and stainless steel. With a highly motivated team and a passion for innovation, we focus on fast response times and customer-oriented solutions. Our certifications according to DIN EN ISO 9001 and 14001 highlight our commitment to quality, the environment, and continuous improvement. We are always looking for dedicated professionals and offer attractive career and training opportunities in a dynamic working environment. Contact us for your next project – we respond within 24 hours!

Machines (4)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Precious metals

Other precious metals

Industries

Packaging industry

Machine tool manufacturing

Plant engineering and construction

Automation and control engineering

Apparatus engineering

Furniture industry

Mechanical engineering

Medical technology

Measurement and control technique, laboratory equipment

Special purpose machinery manufacturing

Building, agricultural and forestry machinery manufacturing

Precision engineering, mechatronics and optics

Electrical industry

Lighting industry

Construction and architectural supplies

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.