Morawetz GmbH

Contacts

Stefan Morawetz

Production

Phone:

E-Mail:

Competencies

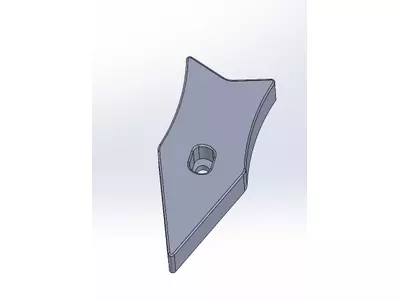

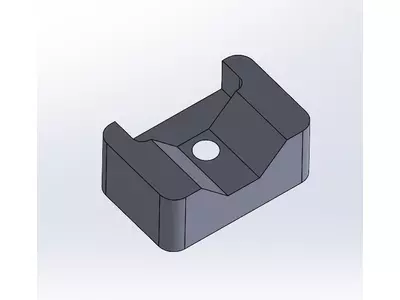

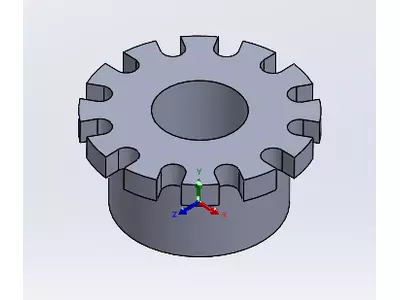

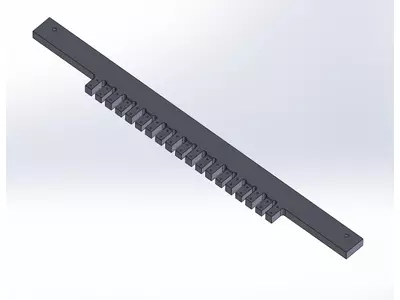

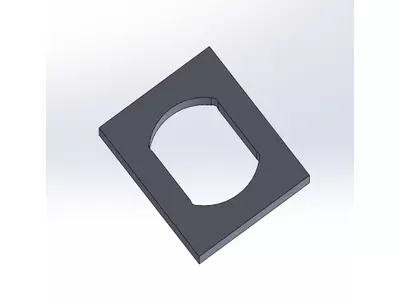

Parts (6)

Technologies

Welding

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Inert gas shielded arc welding (MIG/MAG) | 25 - 100 | 1000 - 2500 | 1000 - 2500 | 1000 - 2500 | - | 25 - 500 | - |

Inert gas shielded arc welding (TIG) | 5 - 25 | 1000 - 2500 | 1000 - 2500 | 1000 - 2500 | - | 25 - 500 | - |

Company description

Morawetz GmbH is an innovative company that specializes in the high-precision manufacturing of parts and components using computer-aided numerical control (CNC). With the latest machines and technologies, we offer tailor-made solutions for various industries. Our dedicated team of experts ensures the highest quality and reliability in every manufacturing process. By continuously investing in the latest technologies and training our employees, we ensure that we are always at the forefront of technological developments. We attach great importance to customer proximity and individual advice. Together with our customers, we develop innovative manufacturing solutions that offer maximum benefit and efficiency. Our services range from prototype development to small series to mass production. Morawetz Technik GmbH stands for precision, quality and sustainable production methods. Rely on our expertise and see how we turn your ideas into reality.

Machines (2)

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Industries

Aerospace and aviation industry

Medical technology

Measurement and control technique, laboratory equipment

Military engineering

Furniture industry

Paper and printing machinery industry

Clean room technology

Shipbuilding industry

Special purpose machinery manufacturing

Telecommunication industry

Packaging industry

Machine tool manufacturing

Apparatus engineering

Drive and gear engineering

Information technology (hardware)

Office machinery and supplies

Chemical industry

Railway and rail vehicles industry

Electrical industry

Power generation and transmission industry

Precision engineering, mechatronics and optics

Household appliance industry

Hydraulic and pneumatic industry

Air conditioning, refrigeration and ventilation industry

Boiler, container and tank construction

Mining and tunnel engineering

Lighting industry

Construction and architectural supplies

Plant engineering and construction

Automotive and vehicle construction

Automation and control engineering

Fittings engineering

Building, agricultural and forestry machinery manufacturing

Mechanical engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.