Pencom Engineering

Contacts

Michał Janczukowicz

Marketing and Sales

Phone:

E-Mail:

Competencies

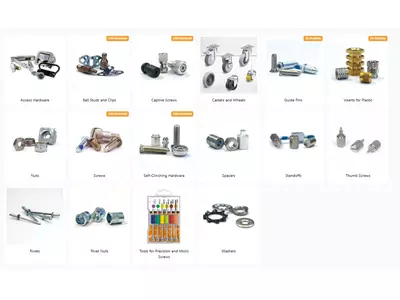

Parts (1)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 10 - 500000 | max. 1000 | - | - | max. 200 | - | - |

Company description

With more than 35 years of experience, PENCOM provides global manufacturing services that combine state-of-the-art technology, engineering expertise, and efficient supply chain management. Our worldwide network of manufacturing facilities and distribution centers ensures on-time delivery, optimized production costs, and consistent high-quality parts. Core Services & Specialties Precision Machining & Metal Forming CNC Machining: Precision parts with complex geometries, tight tolerances, and versatile materials like aluminum, steel, brass, and plastics. From prototyping to production. Metal Stamping: High-speed progressive stamping, custom tooling, and consistent quality assurance for intricate metal components. Automatic Screw Machining: High-speed production for precision-turned components, optimized for cost-efficiency and tight tolerances. Molding & Casting Solutions Plastic Injection Molding: Durable parts using thermoplastics and engineering-grade resins. Includes insert molding for hybrid components and flexible production runs. Die Casting: Lightweight, corrosion-resistant aluminum, zinc, and magnesium parts with close tolerances and automated, high-volume production. Insert Molding: Integrating metal and plastic for hybrid components, streamlining assembly. Fastener & Component Manufacturing Cold Heading: Efficiently produce strong, high-integrity fasteners and specialty hardware with minimal material waste. Assembly Services: Combine molding, machining, and fastener integration to deliver ready-to-use products with reduced lead times. Finishing & Quality Assurance Secondary Services: Surface treatments like plating, anodizing, and painting to enhance aesthetics and durability. Post-Processing: Tapping, deburring, polishing, and more to refine components. Quality Control: Advanced inspections ensure every part meets specifications. Industries We Serve PENCOM’s manufacturing solutions cater to a diverse range of industries, each with unique requirements for precision, reliability, and cost-effectiveness: Automotive: Engine components, electronics housings, interior parts. Aerospace & Defense: Lightweight, high-strength parts built to stringent quality standards. Medical & Healthcare: Biocompatible plastics and metals for durable, precise components. Consumer Electronics: Compact, high-volume parts with fine detail. Industrial & Automation: Robust mechanical parts for assemblies and factory machinery. Energy & Utilities: Corrosion-resistant materials for harsh operating environments. PENCOM’s Quality & Engineering Support ISO-Certified Systems: Our facilities follow recognized quality standards to ensure consistency in every batch. Advanced Equipment & Technology: CNC machines, automated presses, and high-precision tooling deliver reliable results. Design Optimization: Work with our engineers to reduce material usage, simplify part design, and improve product longevity. Prototyping & Testing: Validate part performance and refine designs before committing to full-scale production. Dedicated Project Management: A single point of contact for streamlined communication and timely updates.

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.