STETORN

Contacts

STEFANO BAREL

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

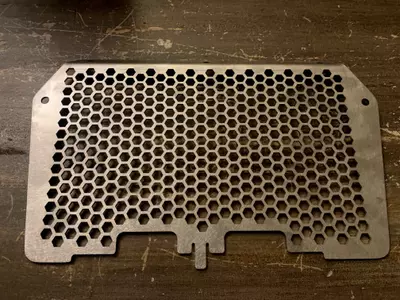

Parts (7)

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 100 | max. 99999998 | max. 99999998 | - | - | - | max. 99999998 |

Laser cutting, tube & section | 1 - 50 | 100 - 6000 | 100 - 6000 | 100 - 6000 | - | - | max. 10 |

Company description

Stetorn is a young and dynamic company specializing in precision mechanical machining. Specifically, we specialize in: DESIGN Using 3D modeling software, we can design parts according to your specific requirements. MACHINING Turning, milling, laser cutting, bending, welding, assembly, and special machining upon request. HEAT & SURFACE TREATMENTS We can perform heat treatments on our parts, such as induction hardening, total hardening, and case hardening. Once the part is finished, according to the customer's specifications, we can perform cold-dip galvanizing, hot-dip galvanizing, nickel plating, and powder coating. TECHNOLOGY 3D modeling software, use of CNC machines, fiber lasers, and state-of-the-art welding machines. We stand out for: QUICK DELIVERIES On-time deliveries thanks to an efficient work organization. EXPERIENCE Although our company is young, we can boast over 20 years of experience in the mechanical machining sector thanks to the skills of our collaborators. FLEXIBILITY Ability to adapt to special requests and urgent changes. ON-GOING ASSISTANCE Technical support and consulting for every phase of the project, from design to production.

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Free-cutting/mild steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Light metals

Aluminium and aluminium alloys

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Cast metals

Cast iron

Industries

Mechanical engineering

Apparatus engineering

Building, agricultural and forestry machinery manufacturing

Special purpose machinery manufacturing

Machine tool manufacturing

Shipbuilding industry

Air conditioning, refrigeration and ventilation industry

Plant engineering and construction

Aerospace and aviation industry

Automotive and vehicle construction

Chemical industry

Furniture industry

Fittings engineering

Construction and architectural supplies

Boiler, container and tank construction

Lighting industry

Packaging industry

Paper and printing machinery industry

Power generation and transmission industry

Railway and rail vehicles industry

Hydraulic and pneumatic industry

Mining and tunnel engineering

Precision engineering, mechatronics and optics

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.