Ulmer Maschinenteile GmbH

Contacts

Dominik Späth

Marketing and Sales

Phone:

E-Mail:

Competencies

Parts (1)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 3 - 200 | 5 - 2000 | - | - | 50 - 400 | - | - |

Full-range turning (including milling) | 1 - 100 | 250 - 2500 | - | - | 200 - 1000 | - | - |

Shaft machining | 2 - 250 | 200 - 1800 | - | - | 30 - 450 | max. 1500 | - |

Company description

Strengths and unique features of the UMT Our focus is in the production of complex and high-precision individual parts and small series for machine building. We manufacture and install assemblies to the finished machine including commissioning and function test. And that since 1995. Our production range we include any kind of turning, milling, grinding, drilling, painting, and assembling. Strengths in staff • We work exclusively with trained and experienced personnel. Thus we are able to build completely different machines including production. • We provide our clients with individual advice to manufacturing and installation, as well as new developments of machines and assemblies. • Through this technical assistance, the customer gets the chance to reduce its costs of production and to develop production-ready components. • Due to shallow levels of management, clearly defined tasks with short decision paths, open exchange of information between and within the areas a fast and flexible adaptation to changing requirements is possible. • Our ams.erp system supports and ensures the transparency of the offer process on the commercial management, from production to installation. • We have a perpetual license for giving our employees. • This guarantee is for customer satisfaction, flexibility, competence and reliability. Technical strengths • We ask ourselves individually to our customers, because we can enable much our know-how and machinery. Ranging from transfer units, machining centers, tool grinding, induction hardening machines, electron beam welding machines, special purpose grinding machines for the aircraft to complex devices for the automotive supplier industry. • Consulting, planning, purchasing, manufacturing, assembly, electrical and service - all from one source. • These are our modern manufacturing. Through the consistent expansion of the production machinery machining centers we are very flexible in processing.We produce cubic components up to a size of 1.80 mx 1.80 mx 1.8 m with the highest accuracy (5 μ). • All machining centers have tool storage with 240-350 tools, palettes, and swivel heads with 5-side machining. In this way we minimize the set up time and can go unmanned shifts. • With our modern universal grinding machines, we can thread, out of round, grind inside and waves up to a size of 200 mm dia x 1400 mm with an accuracy of 1 μ. • With our modern "pick-up" machine, we can carry out the complete turning and milling of turned parts cost. And this up to a diameter of 400 mm. • We assume 3D data into a modern programming system of Open Mind. This error can be prevented and fast programming of the machine is guaranteed. • All parts that we deal with are measured in our quality assurance with modern Zeiss measuring machines and creates audit logs. • All this is a guarantee for quality and precision.

Machines (20)

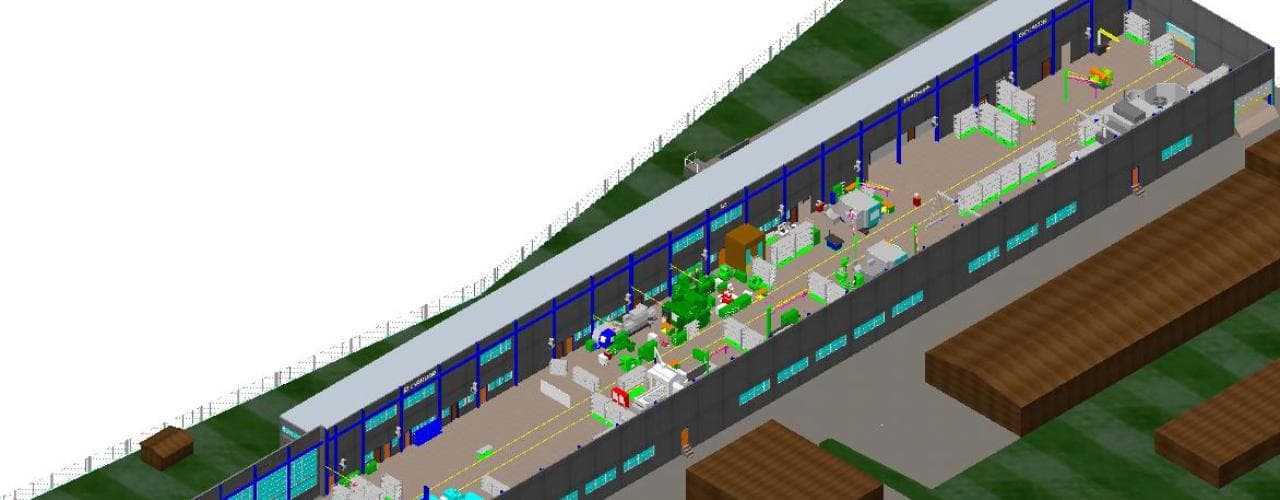

Copmany images

Materials

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Industries

Packaging industry

Boiler, container and tank construction

Apparatus engineering

Chemical industry

Hydraulic and pneumatic industry

Automotive and vehicle construction

Fittings engineering

Construction and architectural supplies

Aerospace and aviation industry

Shipbuilding industry

Telecommunication industry

Drive and gear engineering

Medical technology

Measurement and control technique, laboratory equipment

Precision engineering, mechatronics and optics

Mechanical engineering

Paper and printing machinery industry

Household appliance industry

Railway and rail vehicles industry

Mining and tunnel engineering

Lighting industry

Automation and control engineering

Electrical industry

Air conditioning, refrigeration and ventilation industry

Furniture industry

Information technology (hardware)

Office machinery and supplies

Military engineering

Power generation and transmission industry

Clean room technology

Plant engineering and construction

Building, agricultural and forestry machinery manufacturing

Machine tool manufacturing

Special purpose machinery manufacturing

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.