WB GmbH

Contacts

Competencies

Parts (1)

Technologies

Etching and Spark Erosion

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Spark erosion wire cutting | 1 - 100 | 1 - 360 | 1 - 240 | 1 - 220 | - | max. 500 | - |

Spark erosion countersinking | 1 - 100 | 1 - 950 | 1 - 600 | 1 - 350 | - | max. 1000 | - |

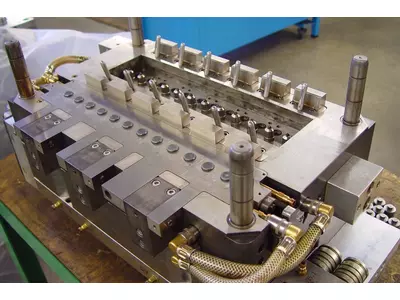

Company description

Werner Breitschädel GmbH has been active in the field of machine and tool construction since 1950. For our satisfied customers we manufacture precise tools and mechanical engineering and plastic parts. To carry out our orders, we have a team of highly qualified employees who are always up to date with the latest technology thanks to regular further training.

Machines (4)

Copmany images

Materials

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Free-cutting/mild steel

Tool steel

Spring steel

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Cast metals

Cast steel

Cast iron

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Non-metal inorganic materials

Graphite

Industries

Automation and control engineering

Electrical industry

Railway and rail vehicles industry

Mechanical engineering

Precision engineering, mechatronics and optics

Special purpose machinery manufacturing

Medical technology

Measurement and control technique, laboratory equipment

Packaging industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.