Wicro Plastics B.V.

Contacts

Tom Croughs

Commercial management

Phone:

E-Mail:

Competencies

Parts (6)

Technologies

Injection Moulding, Extruding

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Injection moulding | 1000 - 99999998 | 1 - 99999998 | 1 - 99999998 | 1 - 99999998 | - | 0.5 - 99999998 | - |

Injection-mould around inserts | 1000 - 99000000 | 1 - 1500 | 1 - 1500 | 1 - 1500 | - | max. 10 | - |

Multi component injection moulding | 1000 - 99000000 | 1 - 1000 | 1 - 1000 | 1 - 1000 | - | max. 10 | - |

Company description

Company Profile – Wicro Plastics & Alligator Plastics Wicro Plastics B.V. is a high-quality injection molding specialist based in the Netherlands, delivering precision-engineered plastic components for a wide range of industries including high-tech, automotive, consumer, and industrial applications. With over 70 years of experience, we combine deep engineering expertise with state-of-the-art production technology and a strong commitment to customer success. In 2025, Alligator Plastics – a well-established injection molding company with locations in Eindhoven and Son & Breugel – joined the Wicro Group. Together, we offer expanded capacity, broader technical capabilities, and direct access to the Brainport high-tech region. This integration strengthens our position as a full-service, knowledge-driven production partner in the Benelux. Our Capabilities - Injection molding (thermoplastics, including food-grade and technical materials) - Product development & co-engineering - Tooling design and coordination (outsourced to trusted partners in Europe and Asia) - Assembly & post-processing - Production automation & in-line quality control - Small to mid-sized series (typically from 5,000 to 10,000,000 pcs) What We’re Good At - Precision molding of technically demanding parts with tight tolerances - Supporting early-stage product design through DfM feedback - Managing complete mold projects, including validation, T1/FOT/SOT - Delivering consistent quality for both mass production and recurring series - Short, transparent communication lines and proactive project follow-up What We Value At Wicro, we aim for long-term partnerships based on reliability, technical excellence, and mutual growth. Quality is at the core of everything we do — not only in the parts we produce, but also in how we communicate and deliver. We think along with our customers, not just as suppliers, but as true production partners.

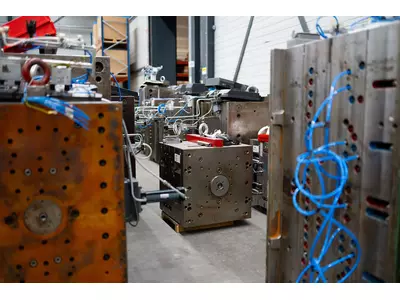

Copmany images

Materials

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Industries

Special purpose machinery manufacturing

Lighting industry

Household appliance industry

Furniture industry

Fittings engineering

Electrical industry

Aerospace and aviation industry

Air conditioning, refrigeration and ventilation industry

Automation and control engineering

Automotive and vehicle construction

Boiler, container and tank construction

Building, agricultural and forestry machinery manufacturing

Chemical industry

Clean room technology

Construction and architectural supplies

Railway and rail vehicles industry

Packaging industry

Office machinery and supplies

Military engineering

Medical technology

Mechanical engineering

Measurement and control technique, laboratory equipment

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.