Discover specialized suppliers for engraving milling on Techpilot. Our platform connects buyers with suppliers who use modern engraving and milling technologies to create precise engravings. Use the e-sourcing process to find the best suppliers.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

We also manufacture using the latest technology components to customer specifications. - Diameter up to 20mm - Knurling, threading, reaming, drilling, slotting - Cross-processing by-driven tools possible - Especially stainless steels such as 1.4021, 1.4034, 1.4301, 1.4305, 1.4310 - Processing of materials such as brass, silver, bronze, plastic, cutting steel - Production of small modules possible (assembly, pressing, Laserscheweißen) - Individual labeling with Article no. possible by laser technology - 5-axis milling machine for post processing of complex components, as well as for pure Fräsfertigung - Item manufacturing possible up to series production of up to 30,000 pieces. Precision turned parts to customer specifications. Possibilities are rolling smallest diameters up to complex machining with thread and smooth surfaces.

Founded

1993

Employees

10 - 20

Certifications

Wellendingen

Germany - 78669

MRE - PHN is a French group specialized in plastic injection (PP, PA, POM, ABS, PC ...) and overmolding (Rubber, PVC, Elastomer ...). Our two production sites in France and Romania produce and deliver our customers all over the world. We cover all the process from design to delivery since 1908.

Founded

Employees

50 - 100

Certifications

Blangy-sur-Bresle

France - 76340

Founded

2000

Employees

100 - 200

Certifications

Kaunas

Lithuania - LT-47175

Design&Engineering produces machine parts using the machining processes of turning and milling technology on CNC machining centers as well as turning and milling machines with digital displays for individual parts up to series production. In addition, D&E produces high-strength functional components and covers and the like using additive 3D printing processes, including quality certificates. Assembly work and documentation complete the profile.

Founded

Employees

< 5

Certifications

Nersingen

Germany - 89278

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Binder Automation is a modern mechanical engineering company with 30 years of experience. Our field of activity is the development and manufacture of customer-specific special machines. Our individual complete solutions cover all relevant fields of activity of your project. From planning, design, manufacture and programming to service and maintenance by Manufacturing facilities: Our service areas are in areas such as - assembly and machining - Transfer and handling - Check and measure - Production lines and transfer lines - Special equipment, special machines - test stations - setting and riveting devices

Founded

1991

Employees

20 - 50

Certifications

Lonsee

Germany - 89173

ZENTRIQ manufactures high-precision aluminum, stainless steel and titanium parts for the semiconductor industry, aerospace, medical technology, racing and alternative energy. After machining, the manufactured parts are finished in a specially set up department. The module is assembled in a quality class 6 clean room, which corresponds to an contamination of less than 1 million particles with a size of 0.1 µm per m3 of air. ZENTRIQ has 40 high-tech machining centers in the turning and milling sector and processes raw materials up to a diameter of 600 mm (turning range) and a processing length of up to 4000 mm (milling range). Our 3 and 5-axis machining centers enable us to cover a wide range of customer requirements.

Founded

1998

Employees

100 - 200

Certifications

Anthering

Austria - 5102

Based on a practical experience in the field, Metal-Inov Engineering SRL can offer you mechanical processing services, CAD design, CAM processing. Our main activity is the CNC milling processing operations, on a vertical center with HAAS brand numerical control, with a working volume of 762x406x508mm with an accuracy of +/- 0.02mm. The materials we usually work with are aluminum, steel, stainless steel, and in general any cutting material. Due to the knowledge in the field of computer aided design we can execute any geometric shape that can be transposed in CAD2D / 3D format, the parts can be made by 2D milling or by 3D milling (complex geometries / volumetry) Together with our collaborators we can also offer surface treatments so as to deliver the ready-to-use parts. CONTACT US by e-mail or telephone, in order to obtain more details regarding the mechanical processing operations performed by our professionals

Founded

2021

Employees

< 5

Certifications

Satu Mare

Romania - 444000

CP Tech GmbH from Büren has been part of the Nedschroef Group since June 2017 and focuses on innovative in-house products, engineering services, high-performance components and complete solutions for the automotive, motorsport and aviation industries. The focus of the corporate strategy is on the development of new mobility concepts, shaped by global trends such as e-mobility, lightweight construction, networking, sustainability and autonomous means of transport. With around 210 employees, CP covers the entire value chain from development through project management, production and assembly to testing and validation of complete vehicles. The core competence of CP lies in the production of high-precision lightweight components from high-strength steels and the interaction of hand-held welding processes, heat treatments, mechanical processing, including the associated device concepts. CP also has its own agency in Shanghai (China) and works there with various companies.

Founded

2006

Employees

100 - 200

Certifications

Büren

Germany - 33142

As a specialist company in southern Germany, Mayer offers contract manufacturing for welded structures with mechanical processing. In addition to welding in various processes and mechanical processing on CNC-controlled moving column machines, our competencies include many other processes related to the processing of steel. At the Heidenheim site, we offer a unique production depth and modern machinery, which enable fast response and short delivery times. Our uncompromisingly high quality standards are reflected in all manufacturing processes and in our trained specialists.

Founded

1850

Employees

20 - 50

Certifications

Heidenheim an der Brenz

Germany - 89522

Your specialist for mechanical metal processing in Friedberg (Bavaria) We are a highly specialized company for mechanical metal processing and have been offering timely, order-based single-part and series production for mechanical and plant engineering for over 20 years. Our range of services includes the production of welded structures, the production of turned parts and milled parts, ready-to-assemble assemblies including development and CAD design.

Founded

2001

Employees

20 - 50

Certifications

Friedberg

Germany - 86316

The object of the company is • engineering services; • Development, manufacture and sale of mechanical and mechatronic devices, hardware, software and control products; • Mechanical, metal, apparatus, plant and vehicle construction as well as their distribution, assembly, commissioning and maintenance; • Order processing in wood, metal and plastic.

Founded

2020

Employees

5 - 10

Certifications

Geretsried

Germany - 82538

Our drive elements made of plastics are manufactured exclusively by injection, optionally at special rework in machining processes. With our advanced injection molding machines and by ongoing investment in current technology, we are able, our products cost-effective and automated at the highest level to manufacture. The injection molding process allows us to produce both parts with high accuracy as well as mass-produced in a short time. The necessary tools for this are either already available or are prepared by Zipperle itself. In addition, we also manufacture special parts in various geometries and in a variety of chemical-resistant plastics. AKROTEC - a new material made of aliphatic polyketone (PK) This material has high mechanical properties, has very good chemical resistance and toughness Shock loads, as well as a very high abrasion resistance.

Founded

Employees

20 - 50

Certifications

Renningen (Malmsheim)

Germany - 71272

We are specialized to manufacture according to customer drawings parts from plastics such as Hgw 2082 ..., HP ..., PVC, POM, PA, GRP. We work with our experienced staff on the latest machines and can also meet current customer needs.

Founded

2000

Employees

20 - 50

Certifications

Sehmatal-Cranzahl

Germany - 09465

Leutz Lötsysteme GmbH is an innovative, dynamic and flexible family company. We offer the development, construction and manufacture of parts and devices.

Founded

1986

Employees

5 - 10

Certifications

Albershausen

Germany - 73095

Since its founding by ALOIS RETTENMAIER in 1914, the company is in Familienbesitz.Als trained steel engraver founder placed particular emphasis on sophisticated and detailed elaboration of designs and embossing tools. Since then our product range has also for the club need constantly erweitert.Heute and in the future, it is our endeavor to meet the highest quality standards. Skilled employees enable the production from design to final product under one roof. Our strength is to realize special requests of any size carefully and at short notice. Constant advancements in tool made it possible to manufacture precision stamping and bending parts, among other things for well-known automobile manufacturers. In addition, we are a manufacturer of keychain, belt buckles, tokens, badges, bottle openers, letter openers, lettering, advertising signs, tie clips ... Our assortment is huge.

Founded

1914

Employees

20 - 50

Certifications

Schwäbisch Gmünd

Germany - 73525

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We, the HES Factory, are a young company and want to help in this way with our high-quality and holistic services to implement your projects.

Founded

2023

Employees

5 - 10

Certifications

Neu-Ulm

Germany - 89233

BMmetal is an industrial unit specialized Machining (Turning & Milling) . A member of the B&M group , it offers its company a wide range of services, always striving for Rigor and Quality in each product it produces. Operating from the municipality of Óbidos, we work for the whole world. We are prepared, both in technical equipment and in specialized human resources, to carry out work with any type of metal in order to materialize each project. Our focus is always the specifics requested by each client. All the raw materials used are chosen for their quality, in order to ensure a high quality finished product.

Founded

1997

Employees

100 - 200

Certifications

Óbidos

Portugal - 2510-752

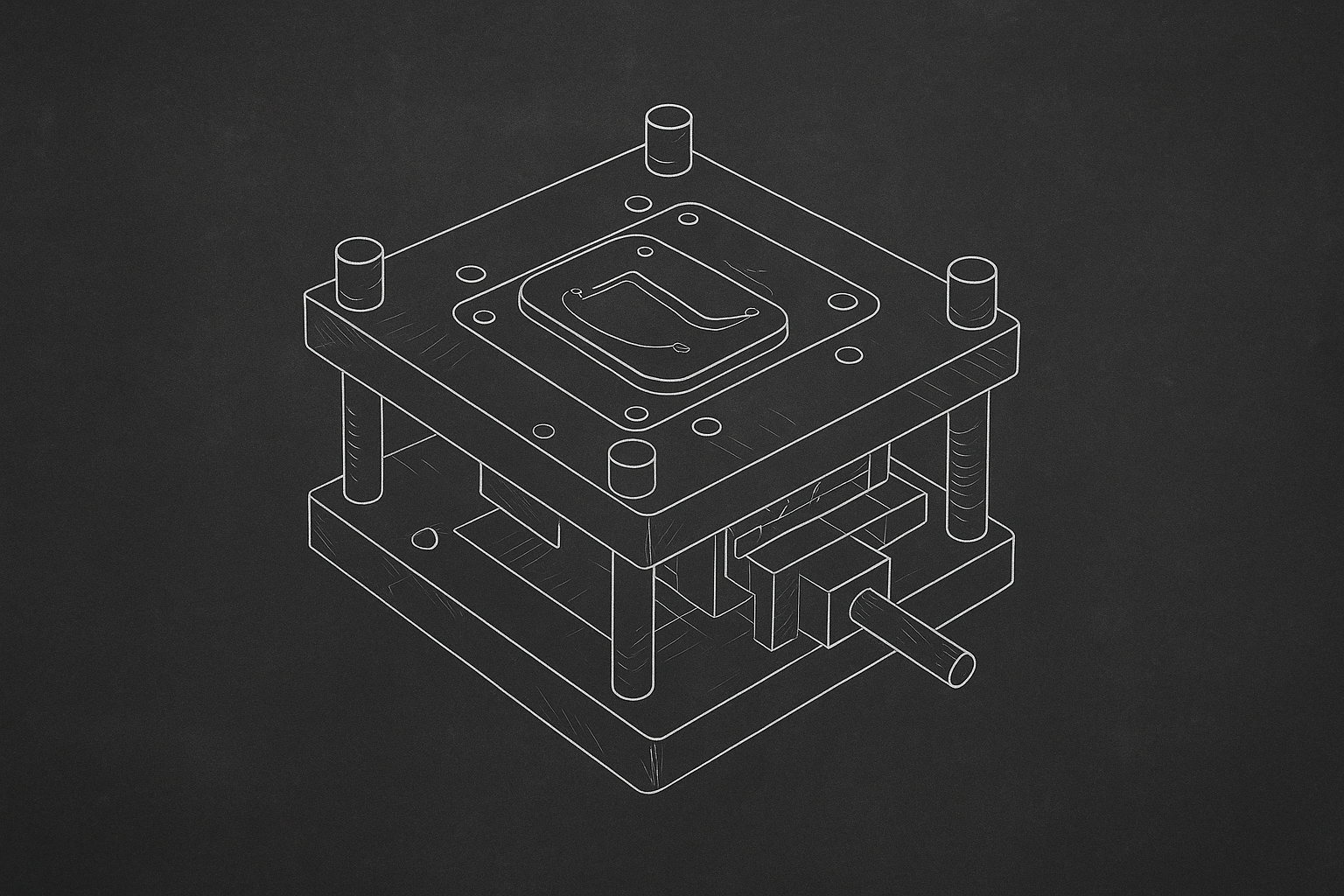

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002

With around 30 injection molding machines ranging between 40-200 tons of feed, rekuplast GmbH is the perfect partner for manufacturing components with an injection weight of 0.05 to 500 grams. Our machinery consists primarily of Arburg and Demag Sumitomo machines. This puts us in an excellent position in terms of accuracy and reliability. This is also reflected in our permanently statistically monitored machine and process capabilities. In our injection molding production, we produce quantities of 100 to 40,000,000 pieces per year for individual parts. In higher quantities, the processes are fully automated, depending on the complexity of the component. To ensure perfect series quality, every component is produced with the suitably configured machine. The feed and screw ratio are optimally tailored to the component — without compromise! Compliance with specified process parameters is a matter of course. Our organization is structured in accordance with the 5S philosophy in terms of order and cleanliness. In doing so, we attach great importance to a targeted material flow and use a portal conveyor for this purpose, which connects production with storage and shipping. This ensures FIFO and batch traceability, from raw material to delivered component.

Founded

1969

Employees

50 - 100

Certifications

Wertheim

Germany - 97877

Production profile Industrial service providers and manufacturers of capital goods • Development, design, manufacture, assembly and commissioning of components or complete systems according to customer requirements • Individual solutions with exact Manufacturing accuracy • Repairs, maintenance, conversion, implementation, expansion of existing machines and systems • Industrial service • Compressed air technology / service (specialized in KAESER compressors) • item pluspartner • Arms manufacturing license Main profile • Special machines, systems, aggregates and components for the capital goods industry • Filter systems for particle filtration • Container construction • Steel construction • mech. Machining workpieces • Refurbishment and revision of drilling and construction machines • Precision machining in automatic construction down to the zero dimension range • Production of weapon parts and complete weapons • Tool making • Production of analog film production systems Services etc. • technological steel construction • Assembly services for all chemical, pharmaceutical and production engineering apparatus and plant engineering • All types of welded structures • Profile construction • Aluminum profile construction • Industrial services • Maintenance, inspection and servicing of mechanical equipment • Tool repair (grinding, sharpening) • Repair of film and photo technical systems

Founded

1991

Employees

20 - 50

Certifications

Bitterfeld-Wolfen

Germany - 06766