Discover specialized suppliers for 3D form milling on Techpilot. Our platform connects buyers with suppliers who use advanced milling technologies to create complex 3D shapes. Use the e-sourcing process to find the best suppliers.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

As a powerful company, we offer technical expertise in the field of metal processing. With qualified staff, know-how, practical experience and modern machinery, we guarantee the highest quality and punctuality. In the context of metalworking, we offer services ranging from single parts to assemblies up to complete production. We are your efficient partner in precision parts machining all materials: * Stainless steels * Heat-treatable steels * Cutting steels * Silver Steel * Plastics * Aluminum * And much more Machinery • CNC lathe MoriSeiki NL 2500/700 SY o with bar loader to 80mm diameter o Y-axis and driven tools counter spindle o machining length 700mm o Year 2008 • CNC lathe Mazak Quick Turn Nexus 100 II M o with bar loader to 42mm diameter o driven tools o Year 2007

Founded

2007

Employees

5 - 10

Certifications

Berngau

Germany - 92361

Founded

-1992

Employees

5 - 10

Certifications

janjevo

Albania - 14050

As leading experts in tool making, we distinguish ourselves through our expertise in cold and hot forming. We offer our customers reliable toolmaking solutions for high-strength and ultra-high-strength steels, aluminum forming and carbon products that are tailored exactly to their individual needs. Mechanical processing at weba Werkzeugbau stands for maximum precision and innovation. With our versatile machinery and decades of experience, we manufacture your components in the field of mechanical, plant and tool manufacturing — whether small parts, medium size or large part processing. Machine park: over 30 milling machines Products: Manufacture of workpieces in any shape with high precision using 5-axis milling machines Maximum processing dimensions: 8,000 x 3,100 x 1800 mm Indoor cranes: up to 25 t Precision: accuracy of +/- 0.01 mm is possible Programming: Creation of CNC programs by in-house programming department using Esprit and WorkNC Data formats: CATPart, CATProduct, DWG, DXF, Siemens NX, STEP, IGES, VDA

Founded

1982

Employees

200 - 500

Certifications

Dietach

Austria - 4407

Our company was founded in 1985 as a mobile portal machine tool manufacturer. To overcome the crisis of the 90s, collaboration began with the company ORTHOFIX S.r.l., a world leader in external orthopedic products, in particular, the engineering of prototypes and pre-series was studied. As the stagnation in machine tools persisted, in 1997, we switched to the production of orthopedic modular systems on behalf of ORTHOFIX S.r.l., including the construction of bone cortical screws. We subsequently added other customers, always consistent in their qualitative needs, such as OMV MACHINERY S.r.l., a leader in the production of machinery for the production of food containers, the P. BERETTA WEAPON FACTORY in Gardone Valtrompia, BALZARIN S.r.l. which deals with the design, construction and processing of sheet metal molds. We specialize in the processing of steels according to UNI EN 10088-1 AISI/ASTM, aluminum alloys, plastic materials (PSU-Polysulfone, Pom C, Nylon, etc.) and thermoforming materials. We have chosen to have few qualified customers so that we can guarantee, not only quality, but also delivery. This is why we manage our warehouse of parts agreed with the customer. In 2023, the company had more than one million euros in turnover and can count on 10 qualified employees. Thanks to the support of our qualified suppliers, we are able to provide surface treatments such as hard anodic oxidation after tumbling, vacuum hardening, sandblasting, stainless steel polishing, electropolishing and laser marking. Our production is continuously monitored according to quality specifications, designed to exceed the strictest standards, and everything is archived for traceability of both production and raw material.

Founded

1985

Employees

5 - 10

Certifications

Pescantina

Italy - 37026

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

HISTORY The craft business, founded in 1961 by Mr. Johannes Richter Senior, has been successfully continued and expanded by Mr. Peter Richter to this day. Our company has been located in the GADA / Bergkirchen industrial estate since 2009. In 2013 we were able to name Mr. Stefan Frank alongside Mr. Peter Richter as managing director. OPPORTUNITIES With our modern machinery and corresponding know-how, we can deal individually with all tasks. TRAINING OPERATION As a conscientious training company, we are committed to providing information events and offers on site, future-oriented and with social responsibility. EMPLOYEE All of our employees were trained and taken on within our company. In addition, further education and training are carried out.

Founded

1961

Employees

5 - 10

Certifications

Bergkirchen/GADA

Germany - 85232

The company was founded in 1997 Adelhausen. In the early days, the service sector amounted to mold making and prototyping for the plastics processing. Due to the constant change in the economic situation in the following years, the company has become more specialized on the automotive industry. By investing in modern machinery other services could be offered. The company is now active in the fields of jigs and fixtures, CNC milled parts and the assembly. The farm size is presently 10 employees and trainees as an industrial mechanic in the area of production technology.

Founded

1997

Employees

10 - 20

Certifications

Adelhausen / Straufhain

Germany - 98646

Adestra metalworking, flexible modern enterprise, the sheet metal and tube machining, and mechanical machining can offer turning and milling. We design, produce and assemble according to customer requirements: housing, terminals, machines, machine covers, custom solutions, components and assemblies.

Founded

1994

Employees

50 - 100

Certifications

Pilsen

Czech Republic - 301 00

solder masks soldering form Lakierträger Contract manufacturer milling 5 axis milling Milling plates jig Assembly

Founded

2010

Employees

10 - 20

Certifications

Soest

Germany - 59494

Your competent partner for manufacturing mechanical products on CNC-controlled processing machines. VETEC Zerspanungs- und Feinwerktechnik GmbH has been successfully manufacturing complex mechanical individual products and assemblies for over 30 years. The focus is on both single-part and prototype production as well as series production for small and medium-sized quantities according to your specifications. We see ourselves as an innovative manufacturing company for high-quality precision engineering. A creative team of highly trained specialists, technicians and engineers enables the efficient implementation of individual manufacturing services with consistently high quality. Our motivation, continuous modernization of our machinery and close cooperation with our customers are the basis of our corporate success. performances As a competent partner for CNC machining, our long-standing customers particularly appreciate the close cooperation in optimising their projects for production and comprehensive advice on the selection of possible materials and surface and material treatments. We can draw on over 20 years of experience here. Our specialty is primarily high-precision and complex components. We have a lot of experience in processing a wide variety of materials. With regard to technical requirements and project management, we respond flexibly to the wishes of our customers. We work for a wide range of sectors of the economy. Our customer base includes companies from the automotive industry, medical technology, aerospace, the electrical industry, many companies with innovative products, research and development companies and much more. We offer you the following services: CNC turning CNC milling Customization development and construction during production Assembly of components Finishing according to our service profile (see brochure and website)

Founded

1992

Employees

20 - 50

Certifications

Rostock

Germany - 18069

PREMETEC develops solutions for customer-specific measurement and testing tasks with the necessary upstream or downstream automation steps for our customers. We implement the measuring devices, gauges, assembly systems and systems we supply in-house until they are put into operation. We represent almost all specialist machine construction sectors: from mechanical design to electrical project planning, control cabinet construction, PLC and robot programming (Siemens, Kuka, Yaskawa), parts manufacturing (turning, milling, flat and cylindrical grinding), assembly, commissioning and service. You can find some examples of our products in the link. https://premetec.de/de/leistungen/produkte You can find more applications here on the YouTube channel. https://www.youtube.com/channel/UCvoLYgt6TPaNvzd0Uhh3hEw

Founded

1994

Employees

20 - 50

Certifications

Suhl

Germany - 98527

Production of molded parts of rigid polyurethane foam. From individual and on small series up to max. 10,000 units / year. Post-processing on a 5-axis CNC system directly in the house.

Founded

2005

Employees

10 - 20

Certifications

Dierdorf-Wienau

Germany - 56269

TCM Germany is a subsidiary of TCM International GmbH. The headquarters of TCM International GmbH are in Stainz (Austria). In addition to numerous holdings, it has branches in Germany, Luxembourg, Poland, the Czech Republic, Hungary, France and China. As an innovative technology partner in machining production, the TCM Group offers a diverse portfolio of services. This ranges from the tool trade and output systems of the “TOOLBASE” brand to the complete, productivity-oriented TOOL MANAGEMENT service. In order to be able to support TCM customers even better and to meet modern requirements of "Smart Production", the company WinTool with the tool management software of the same name is one of the cornerstones of the TCM Group. The TCM company portfolio is rounded off by its own training program in which technical expertise on machining processes and their environment is imparted in a modular and manufacturer-independent manner.

Founded

1996

Employees

500 - 1000

Certifications

Gladbeck

Germany - 45966

In addition to well-founded technical know-how, we use the latest CNC technology in production. The efficiency of modern machines enables low manufacturing costs from sample and individual parts to quantities of several thousand parts

Founded

1995

Employees

10 - 20

Certifications

Bernau

Germany - 16321

PSAPET PROD-COM SRL is a high-precision CNC manufacturing company based in Romania, specialized in aerospace, defense, industrial equipment, and high-accuracy mechanical components. With more than 28 years of experience and a highly skilled engineering team, we deliver complex machined parts with top-level precision, consistency, and full quality traceability. Our production systems are certified according to ISO 9001 and AS9100, enabling us to manufacture safety-critical components for the aerospace and aviation industry. We operate an advanced CNC workshop equipped with Okuma, Victor, Hyundai WIA, and Schaublin machines, capable of high-accuracy turning, milling, multitasking operations, and 3D machining. Core Capabilities CNC Turning • Maximum turning diameter: up to 400 mm • Maximum turning length: up to 1000 mm • Multi-axis turning + milling on Okuma Multus • High-precision shafts, bushings, housings, flanges, threaded parts • Prototype → small & medium series production • Tight tolerances down to ±0.005 mm depending on geometry CNC Milling • 3-Axis and 5-Axis CNC machining • Workpiece size up to 1000 × 600 × 500 mm • Complex 3D surfaces and structural components • Pocketing, contouring, engraving, thin-wall machining • High surface quality and precision finishing Aerospace & Aviation Expertise • Machining of aluminum, stainless steel, titanium, and special alloys • Components for mechanical assemblies, aerospace brackets, housings, fixtures, and safety-critical elements • Documentation and process control according to AS9100 • Full traceability for materials, processes, and inspections • FAIR (First Article Inspection Report) according to AS9102 • Manufacturing support for prototypes and serial production Quality & Inspection • CMM dimensional inspection • In-process & final inspection • FAIR / PPAP / CoC documentation • Measuring instruments calibrated and certified • Quality culture implemented in every production stage Company Overview • Production area: 900 m² • Employees: 20–50 • Founded: 1996 • Turnover: 1M EUR • Certifications: ISO 9001, AS9100 • Flexible production: prototypes, one-off parts, small batches, medium series Why Work With Us • Certified and trusted supplier for aerospace & high-precision industries • Excellent machining accuracy and repeatability • Fast response, flexibility, and professional communication • Modern CNC equipment and experienced engineers • High reliability, stable quality, and long-term partnerships

Founded

1996

Employees

20 - 50

Certifications

Bacau

Romania - 600384

DVM Technology provides experts in metalworking, CNC machining, plasma cutting, welding, and custom design services to provide high-quality solutions for projects of any size.

Founded

Employees

< 5

Certifications

Pirot

Serbia - 18307

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our company offers precision engineering and more from one source. On a modern, computer-aided machine tools we mill prototypes, individual parts and series parts. Using the latest machining centers we work with high precision milled parts up to 5 pages in one setting. This complex machined parts can be manufactured economically. The NC programs are prepared for programming on workstations. We can easily your drawing dxf data in formats dwg, step, igs, vda, sat assume. Materials and work area We process the materials of aluminum, iron, cast iron, steel, titanium, brass and plastic The maximum working range of our machines is 500x500x400 mm Program of delivery Ready for renowned customers from different industries and we edit: Bearing, housing, plates, linear units, assembly units, handling units, grippers, guides, levers, bars, distances, angles, baking, clasps, frames, covers, holders, body, castings, profiles Assemblies Complete assemblies and devices are manufactured by us ready for installation including the given surface treatment and fitted.Our own tool enables the production of stamped and bent parts

in small and medium-sized batches. Through our wide range of possibilities for cutting and non-cutting processing results in a wide range of activities. Our services are completed by: Surface treatments such as Trowalieren, polishing, grinding and sandblasting Surface coatings such as anodizing, chromating, burnishing, nickel plating, etc. Heat treatment processes such as carburizing, nitriding, inductive hardening. Proven Quality All products are subject to during production and before delivery to continuous quality control by our qualified staff to meet our demand for a zero-defect production.

Founded

1922

Employees

Certifications

Pforzheim

Germany - 75175

CNC milling contract manufacturing We can manufacture plastic, aluminum, brass, copper, steel, stainless steel and tool steel components using a 3-axis CNC milling machine. Key data Minimum component size: 7 x 7 x 7 mm Maximum component size: 450 x 160 x 150 mm Processing in the uncured state (steels) Prototypes individual parts small series Machining strategies Milling Deburring / chamfering Drill Tapping Reduce Rub Thread milling engraving 3D processing Materials plastic Brass aluminum copper steel stainless steel Tool steel

Founded

Employees

Certifications

Spalt

Germany - 91174

CNC PRODUCTION Turning, milling (5-side machining), grinding with state-of-the-art machining equipment according to current production techniques. We offer machining and high-precision finishing using different production techniques. Individual one-off production as well as serial production according to customer requirements. METAL AND TOOL MAKING Production of tools for hot forging presses (horizontal), complete new production and regeneration offer ready-to-install solutions. Individual areas of the value chain can be processed here.

Founded

1847

Employees

10 - 20

Certifications

Ortenberg

Germany - 77799

Manufacturer of attachment tools for Baumschinen

Founded

1997

Employees

10 - 20

Certifications

Goldenstedt

Germany - 49424

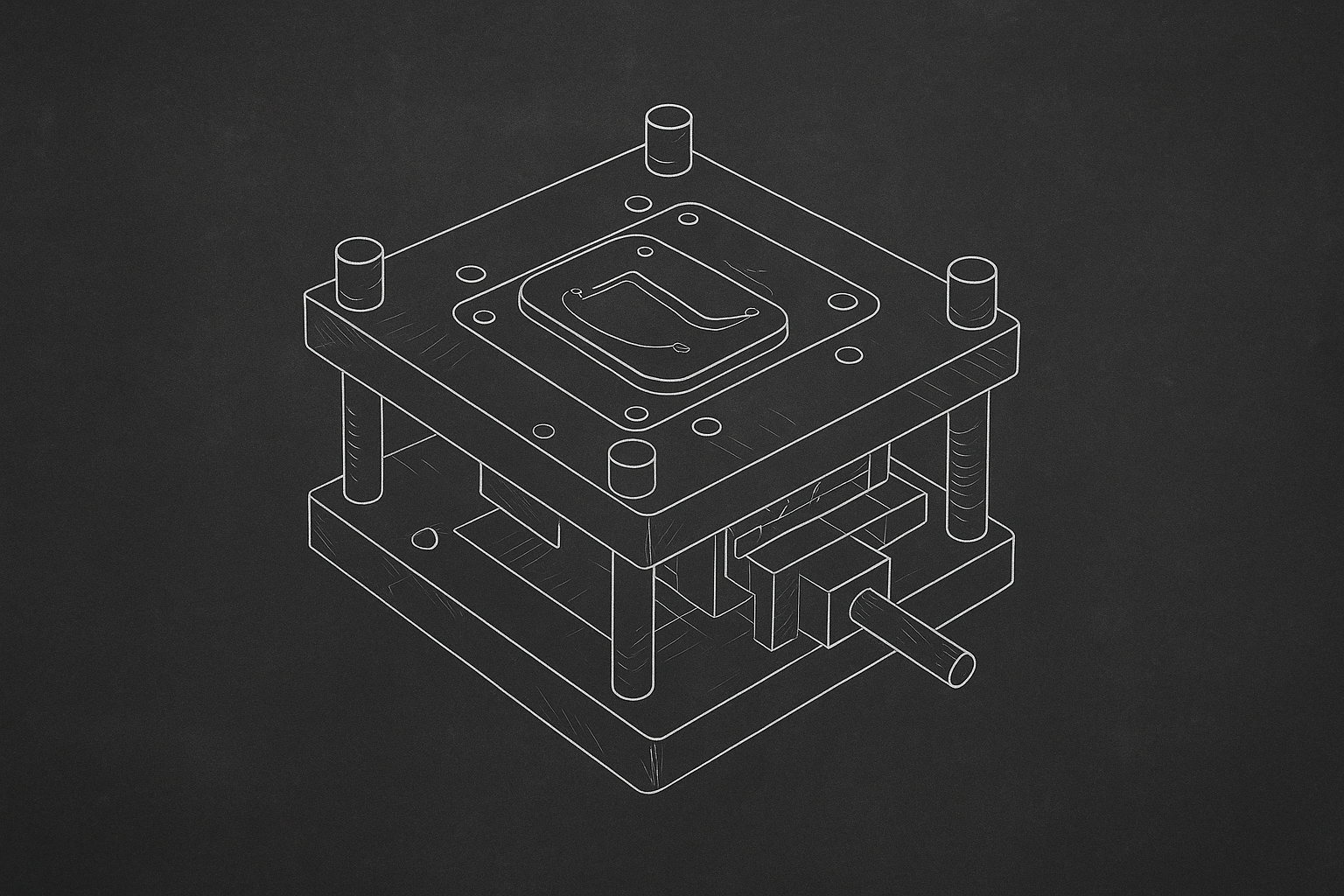

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002