Find specialized suppliers for milling on Techpilot. Our platform offers access to suppliers who use advanced milling technologies to create precise and complex components. Benefit from comprehensive market transparency and efficient supplier search.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

Founded

1994

Employees

10 - 20

Certifications

Haag

Germany - 83527

In the third generation, the 50-year-old Klaus Peter Abel runs the Abel Metallsystem company in Geisa and has since developed it successfully from a pure craft business to an idea generator, pioneer and producer of individual fall protection and railing systems. With over 100 employees, state-of-the-art technology, consistent target group orientation as well as patents and market innovations, Abel Metallsysteme has developed into a permanent partner for architects, construction companies and customers in window and metal construction throughout Europe. This year the company is celebrating its 100th anniversary and is proud of its craft tradition and innovative strength. Abel Metallsysteme has received several awards for this successful development in recent years, for example the strategy award of the Wartburg region and the “Architects`Darling Award 2018” from Heinze GmbH in the “Best Product Innovation Expansion” category. “We have recently received an award from the Erfurt Chamber of Commerce and Industry as an excellent training company. Personally, I am particularly pleased because our employees are the heart of the company for me, ”says Klaus Peter Abel. "I am particularly pleased when we can enable young people to have a successful and good career path."

Founded

1920

Employees

100 - 200

Certifications

Geisa

Germany - 36419

The company Arthur Paluch Metalltechnik was founded in 2016. Even before becoming self-employed, the founder, Arthur Paluch, had been working in the toolmaking sector for over 28 years. During this time, he was able to acquire extensive knowledge in design, production and measurement technology, so that he has expertise in all areas of toolmaking. Our services cover the entire process of manufacturing individual parts as well as small and large series production. This is complemented by our services such as spare parts production, tool repairs or tool adaptations for all types of stamping and forming tools, as well as parts for plastics technology. The team consists of five qualified and motivated specialists and managers who are committed to the company and its customers on a daily basis. In the design and production of individual parts, we are able to achieve a high-quality goal with the help of the latest technologies and methods. After only a short time, we are proud to have built up a customer base consisting of companies from the tool and mold making, mechanical engineering, product development, automotive and food industries. Our customers appreciate APM's speed, flexibility and price-performance ratio. These attributes are part of our mission statement, which we consistently see as our top priority for every order.

Founded

2016

Employees

5 - 10

Certifications

Wickede (Ruhr)

Germany - 58739

Founded

1985

Employees

< 5

Certifications

Zimmern ob Rottweil

Germany - 78658

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We have 26 machining centers for mechanical processing on CNC machines. Components from MWS production are processed there, but also aluminum castings from all casting processes are contracted. The machine park is characterized by flexible horizontal 4-axis machines, 5-axis machines and double-spindle machining centers. Innovative tool concepts guarantee a short cycle time as well as a high degree of automation through the use of handling robots.

Founded

2005

Employees

200 - 500

Certifications

Ternberg

Austria - 4452

PSAPET PROD-COM SRL is a high-precision CNC manufacturing company based in Romania, specialized in aerospace, defense, industrial equipment, and high-accuracy mechanical components. With more than 28 years of experience and a highly skilled engineering team, we deliver complex machined parts with top-level precision, consistency, and full quality traceability. Our production systems are certified according to ISO 9001 and AS9100, enabling us to manufacture safety-critical components for the aerospace and aviation industry. We operate an advanced CNC workshop equipped with Okuma, Victor, Hyundai WIA, and Schaublin machines, capable of high-accuracy turning, milling, multitasking operations, and 3D machining. Core Capabilities CNC Turning • Maximum turning diameter: up to 400 mm • Maximum turning length: up to 1000 mm • Multi-axis turning + milling on Okuma Multus • High-precision shafts, bushings, housings, flanges, threaded parts • Prototype → small & medium series production • Tight tolerances down to ±0.005 mm depending on geometry CNC Milling • 3-Axis and 5-Axis CNC machining • Workpiece size up to 1000 × 600 × 500 mm • Complex 3D surfaces and structural components • Pocketing, contouring, engraving, thin-wall machining • High surface quality and precision finishing Aerospace & Aviation Expertise • Machining of aluminum, stainless steel, titanium, and special alloys • Components for mechanical assemblies, aerospace brackets, housings, fixtures, and safety-critical elements • Documentation and process control according to AS9100 • Full traceability for materials, processes, and inspections • FAIR (First Article Inspection Report) according to AS9102 • Manufacturing support for prototypes and serial production Quality & Inspection • CMM dimensional inspection • In-process & final inspection • FAIR / PPAP / CoC documentation • Measuring instruments calibrated and certified • Quality culture implemented in every production stage Company Overview • Production area: 900 m² • Employees: 20–50 • Founded: 1996 • Turnover: 1M EUR • Certifications: ISO 9001, AS9100 • Flexible production: prototypes, one-off parts, small batches, medium series Why Work With Us • Certified and trusted supplier for aerospace & high-precision industries • Excellent machining accuracy and repeatability • Fast response, flexibility, and professional communication • Modern CNC equipment and experienced engineers • High reliability, stable quality, and long-term partnerships

Founded

1996

Employees

20 - 50

Certifications

Bacau

Romania - 600384

Production and sales of cold forming parts, turning and milling parts. All size ranges and part geometries. CNC single and multi-spindle

Founded

1939

Employees

200 - 500

Certifications

Wuppertal

Germany - 42117

Leutz Lötsysteme GmbH is an innovative, dynamic and flexible family company. We offer the development, construction and manufacture of parts and devices.

Founded

1986

Employees

5 - 10

Certifications

Albershausen

Germany - 73095

HFI is a global tier 1 supplier of precision engineering parts and components for demanding companies in market segments such as: Measurement & Control, Medicine, Semiconductors & Optics, Energy, Defense, Food & Agricultural Suspension. HFI is literally and figuratively about manufacturing extremely precise products from a wide variety of metals and alloys. We achieve this through a combination of highly qualified, practical and experienced professionals as well as advanced and efficient processing methods using the latest CNC-controlled machines. What sets us apart? Our long-standing and solid relationships with our customers. As a reliable partner in our customers' supply chains, we understand the value of stability and continuous delivery of the highest quality and precision like no other. Every day anew. At HFI, we believe in self-development like no one else. We not only manufacture products in accordance with our customers' specifications, but are also constantly developing our own process solutions. Not only in the form of tools, but also through innovative, tailor-made production systems and equipment. Every day, we work on innovations to meet the constantly changing needs and wishes of our customers. We do this from our headquarters in Groenlo in Gelderland, in the middle of the Achterhoek, with a dedicated team of 85 motivated and enthusiastic colleagues. What is unique for HFI on the market is our delivery reliability, our high level of precision work and quality. We strive for nothing less than the highest level of excellence. Proud of what we've achieved so far, we work passionately to exceed all expectations.

Founded

1965

Employees

50 - 100

Certifications

Groenlo

Netherlands - 7141 CX

BMmetal is an industrial unit specialized Machining (Turning & Milling) . A member of the B&M group , it offers its company a wide range of services, always striving for Rigor and Quality in each product it produces. Operating from the municipality of Óbidos, we work for the whole world. We are prepared, both in technical equipment and in specialized human resources, to carry out work with any type of metal in order to materialize each project. Our focus is always the specifics requested by each client. All the raw materials used are chosen for their quality, in order to ensure a high quality finished product.

Founded

1997

Employees

100 - 200

Certifications

Óbidos

Portugal - 2510-752

solder masks soldering form Lakierträger Contract manufacturer milling 5 axis milling Milling plates jig Assembly

Founded

2010

Employees

10 - 20

Certifications

Soest

Germany - 59494

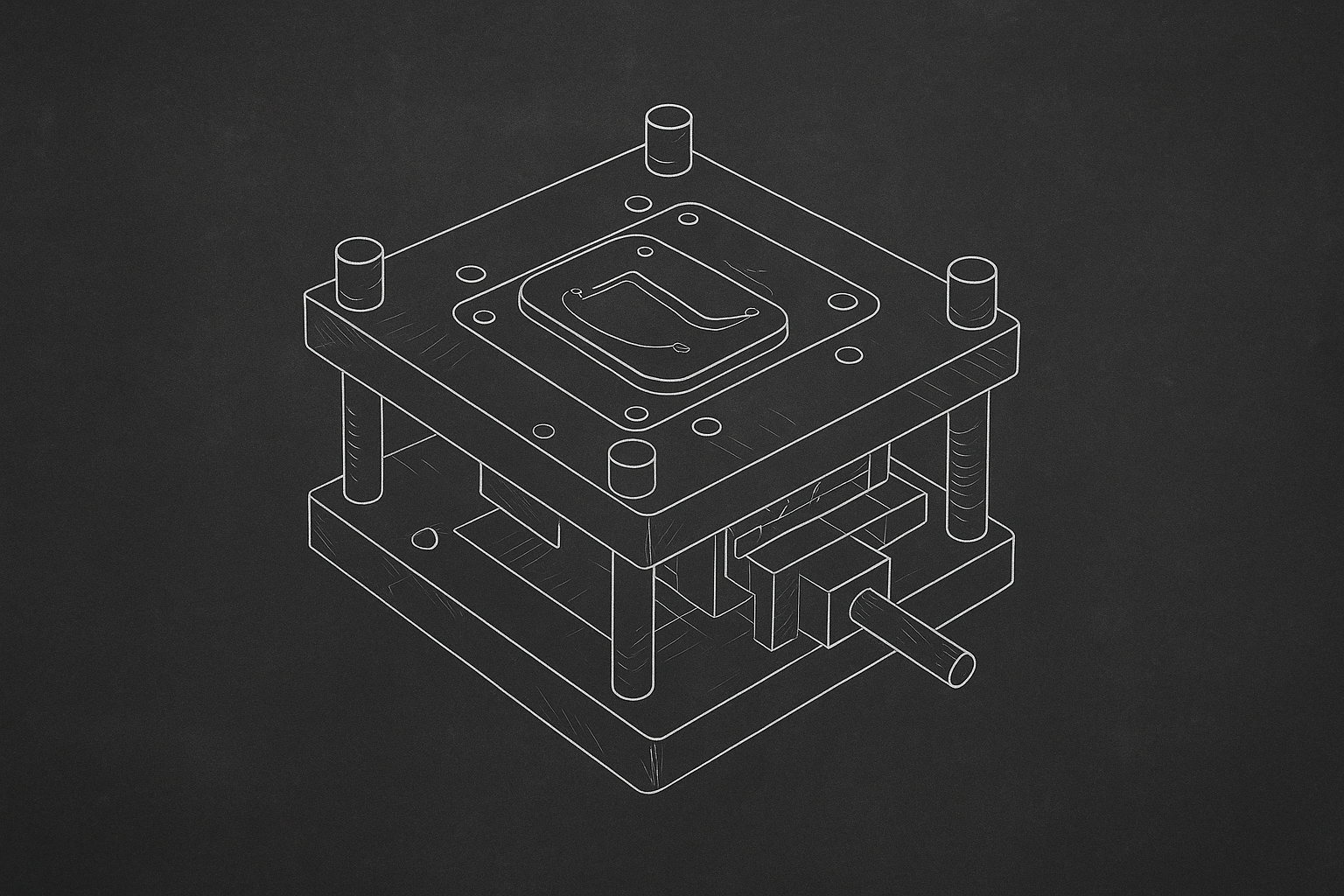

Short profile A + G Präzisionsformenbau As specialists in the precision mold, we offer our customers comprehensive service package. Our service includes the design, development and of course, the manufacture of tools for all areas of plastics engineering. We are capable of producing molds up to a weight of 3500 kilograms. Currently about 30 employees work in our headquarters in Bad Windsheim (BY). The large number of professionals enables us to offer individual solutions in record time. Translation by Google Translate

Founded

Employees

20 - 50

Certifications

Bad Windsheim

Germany - 91438

Adestra metalworking, flexible modern enterprise, the sheet metal and tube machining, and mechanical machining can offer turning and milling. We design, produce and assemble according to customer requirements: housing, terminals, machines, machine covers, custom solutions, components and assemblies.

Founded

1994

Employees

50 - 100

Certifications

Pilsen

Czech Republic - 301 00

The Modellbau H. Brüggemann Gmbh For decades, predominantly classic wood models were manufactured for the foundry industry. In the course of In the course of time, the company structure and range of products changed several times. Due to the continuous development of the company in 1977, a new, larger premises in Hemer, the present headquarters of the company, can be obtained. This allowed the machine park to be expanded and additional production areas to be gained. Today, the company employs 15 highly motivated and specially trained employees on an area of about 1000 square meters. The technical know-how as well as responsibility and quality awareness are kept at the highest level by permanent training and further education. It is our ambition and obligation to satisfy our customers every day and to master the daily new tasks in a personal dialogue with you.

Founded

1906

Employees

10 - 20

Certifications

Hemer

Germany - 58675

Series and component assembly Cable assembly Measurement technology environmental, Vibration and climatic test Mechanical machining

Founded

1973

Employees

Certifications

Markdorf

Germany - 88677

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

Employees

5 - 10

Certifications

Arad

Romania - 317121

PREMETEC develops solutions for customer-specific measurement and testing tasks with the necessary upstream or downstream automation steps for our customers. We implement the measuring devices, gauges, assembly systems and systems we supply in-house until they are put into operation. We represent almost all specialist machine construction sectors: from mechanical design to electrical project planning, control cabinet construction, PLC and robot programming (Siemens, Kuka, Yaskawa), parts manufacturing (turning, milling, flat and cylindrical grinding), assembly, commissioning and service. You can find some examples of our products in the link. https://premetec.de/de/leistungen/produkte You can find more applications here on the YouTube channel. https://www.youtube.com/channel/UCvoLYgt6TPaNvzd0Uhh3hEw

Founded

1994

Employees

20 - 50

Certifications

Suhl

Germany - 98527

Our company was founded in 1985 as a mobile portal machine tool manufacturer. To overcome the crisis of the 90s, collaboration began with the company ORTHOFIX S.r.l., a world leader in external orthopedic products, in particular, the engineering of prototypes and pre-series was studied. As the stagnation in machine tools persisted, in 1997, we switched to the production of orthopedic modular systems on behalf of ORTHOFIX S.r.l., including the construction of bone cortical screws. We subsequently added other customers, always consistent in their qualitative needs, such as OMV MACHINERY S.r.l., a leader in the production of machinery for the production of food containers, the P. BERETTA WEAPON FACTORY in Gardone Valtrompia, BALZARIN S.r.l. which deals with the design, construction and processing of sheet metal molds. We specialize in the processing of steels according to UNI EN 10088-1 AISI/ASTM, aluminum alloys, plastic materials (PSU-Polysulfone, Pom C, Nylon, etc.) and thermoforming materials. We have chosen to have few qualified customers so that we can guarantee, not only quality, but also delivery. This is why we manage our warehouse of parts agreed with the customer. In 2023, the company had more than one million euros in turnover and can count on 10 qualified employees. Thanks to the support of our qualified suppliers, we are able to provide surface treatments such as hard anodic oxidation after tumbling, vacuum hardening, sandblasting, stainless steel polishing, electropolishing and laser marking. Our production is continuously monitored according to quality specifications, designed to exceed the strictest standards, and everything is archived for traceability of both production and raw material.

Founded

1985

Employees

5 - 10

Certifications

Pescantina

Italy - 37026

The company Fermes deals with service processing of brass, aluminum and steel on CNC lathes and milling machines. In its machine park, it has 4 CNC lathes brand and model HAAS ST-10, 4 automatic CNC lathes with bar feeder brand and model HAAS CL-1, as well as 1 CNC milling machine brand and model HAAS VF-1. In addition to CNC equipment, Fermes also owns two channel two-chamber induction (casting) furnaces, deals with casting brass in molds, and also has a hot pressing (forging) machine.

Founded

1992

Employees

20 - 50

Certifications

Novi Sad

Serbia - 21209

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002