Discover specialized suppliers for module assembly on Techpilot. Our platform connects buyers with suppliers who handle complex module and system assembly. Use the e-sourcing process to find efficient partners.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

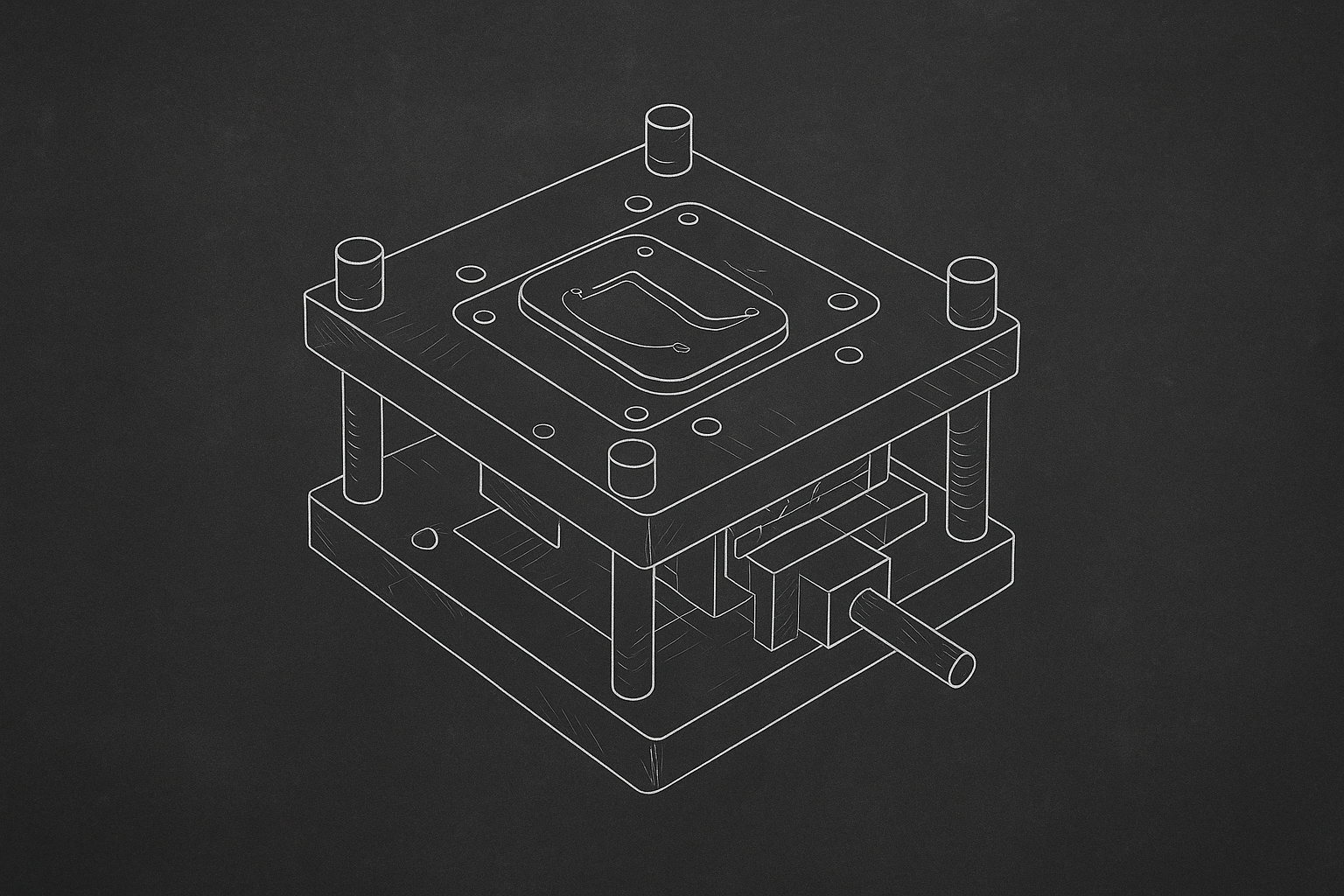

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002

ASAB GmbH Augsburger steel, engineering and tank In 1994, the company ASAB GmbH was founded as a "management buy out" of Pfister Waagen Augsburg. At 2500 sq foot was caught with initial staff of 11 in the apparatus and container. The successful and constant specialization of custom steel and stainless steel the company has ASAB GmbH can grow to 30 employees in the meantime. In 2005 was combined with the partner company Spegel GmbH (www.spegel.de) to a new building with 3600 m² and 400 m² production office in the Ostrachstraße. Today the ASAB GmbH also handles the business operations of Spegel GmbH. The Spegel GmbH acts as a holding company. An ultra-modern machinery along with qualified and motivated employees guarantee the highest precision and quality of our products in very short delivery time. Our motto is: The more difficult, the better! Schweißtechnken and welding processes: Welding and cutting (up to 300 mm in steel) in Autogentechnik Welding with stick electrodes Arc welding in MIG / MAG and TIG process Automatic welding by means of a modern 800 amp UP-conditioning Spot welding machines The following materials we process among others: general structural steels such as S235 (37-2) and S 355 (St 52-3) Stainless steels from 1.4031 to 1.4579, Hastelloy Aluminum alloys Cu-Ni alloys, Black / white joints Production We

Founded

1946/1995

Employees

20 - 50

Certifications

Augsburg

Germany - 86165

Our Company Our company is successful in the supplier market for CNC milling and turning parts active since 1992. Initially founded as a one-man company, the employee and turnover figures and the available machines and premises grew continuously. Our clients include mainly foundries, companies in the automobile industry of agricultural machinery and general machinery as well as a particular degree in the field of hydraulic engineering. Currently we are producing a two-shift system on a highly modern machinery. Our current equipment list can be found in the area of services. Our range of services We have specialized in the CNC milling of prismatic parts such as gearbox, engine parts, hydraulic or other machine components. Loading and unloading of even very large vehicles are under cover. Basically, workpieces can be processed with the following parameters: Prismatic parts: - Max. Edge length 1400x1250x1250 mm - Max. Weight 1500 kg - Bore tolerance IT6 - Positioning accuracy 0.006 mm We are happy to face new challenges and look forward to your inquiry.

Founded

1992

Employees

5 - 10

Certifications

Chemnitz

Germany - 09117

Our company offers precision engineering and more from one source. On a modern, computer-aided machine tools we mill prototypes, individual parts and series parts. Using the latest machining centers we work with high precision milled parts up to 5 pages in one setting. This complex machined parts can be manufactured economically. The NC programs are prepared for programming on workstations. We can easily your drawing dxf data in formats dwg, step, igs, vda, sat assume. Materials and work area We process the materials of aluminum, iron, cast iron, steel, titanium, brass and plastic The maximum working range of our machines is 500x500x400 mm Program of delivery Ready for renowned customers from different industries and we edit: Bearing, housing, plates, linear units, assembly units, handling units, grippers, guides, levers, bars, distances, angles, baking, clasps, frames, covers, holders, body, castings, profiles Assemblies Complete assemblies and devices are manufactured by us ready for installation including the given surface treatment and fitted.Our own tool enables the production of stamped and bent parts

in small and medium-sized batches. Through our wide range of possibilities for cutting and non-cutting processing results in a wide range of activities. Our services are completed by: Surface treatments such as Trowalieren, polishing, grinding and sandblasting Surface coatings such as anodizing, chromating, burnishing, nickel plating, etc. Heat treatment processes such as carburizing, nitriding, inductive hardening. Proven Quality All products are subject to during production and before delivery to continuous quality control by our qualified staff to meet our demand for a zero-defect production.

Founded

1922

Employees

Certifications

Pforzheim

Germany - 75175

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1947

Employees

200 - 500

Certifications

Mechernich

Germany - 53894

We manufacture from individual parts to complete machines. Above all devices, equipment and small series (bis. about 500 pieces). Competent and with great experience, we work every day creative solutions to clients at home and abroad. We like to go unconventional paths. Not just on principle. From experience we know that often just lead them to the goal. We see complex and unusual tasks as challenges, which are particularly exciting. And on whose solution we are really proud of. Down to the smallest detail. Precision Machined develop, manufacture, we measure and assemble for you machines, devices and components - because they can look very closely. What can we do FOR YOU? Basically EVERYTHING that you need for making your products or even the product itself: Machines, devices, assemblies or just items: After our design or customers, including functional test and acceptance report (mechanics) from small parts to large part Small parts min.3 x 3 x 3 mm and up to 0.3 g Large parts max. 8000 x 2000 x 1000 mm and up to 6000 Kg Even "problem parts" of lot size from 1 to 200 CNC turning and milling parts in 4 - and 5 - axis machining or multi-sided machining in one clamping position. For everyone, including stainless, high strength and hardened steels, aluminum, non-ferrous metals and plastics, including fiberglass-reinforced Basic frames and components made of steel or aluminum welded construction or cast version. fully assembled mechanical structures with high precision (15 microns) for various applications Workpiece-related fixtures with unit weights up to 6000 kg (hydraulic and / or mechanical) for multi-sided machining and multiple voltage according to our own design or customer specifications * 4-WAY JIG * 1-UP JIG * SWING CLAMPS * MANUAL CLAMPING DEVICE Device body (tombstone / rake / tension towers) Teaching and prototypes Mechanical assemblies and components for machine tools and measuring machines manufacturers such carriage, brackets, recordings etc. 3-D machined parts, mold frames and accessories for the tool and mold according to drawing and record Special parts and unique items according to sample or drawing One of our specialties is the Hard Milling and Boring workpieces made of hardened steel or titanium

Founded

1994

Employees

20 - 50

Certifications

Geislingen an der Steige

Germany - 73312

The GEBATEC GmbH was founded in 1980 and has since developed into a specialist in the field of development and production of customized switching elements. Among other things, we produce micro switch and contact pins of the highest quality. For many years in our home a quality management system introduced in accordance with DIN EN ISO 9001 and certified. We are counting on all of our customers to the A-suppliers. Schedule and quality loyalty are at the top with us. And this at a fair price. Convince yourself of our competence and inform yourself about our many products. Whether snap-action switch / micro switch, pins, or other products - can be specifically tailored to your products - you will be surprised at how affordable - even in small and medium quantities required. GEBATEC - your partner for high quality production of snap switches / micro switches and other customer-specific switching elements.

Founded

1980

Employees

5 - 10

Certifications

Lohra

Germany - 35102

solder masks soldering form Lakierträger Contract manufacturer milling 5 axis milling Milling plates jig Assembly

Founded

2010

Employees

10 - 20

Certifications

Soest

Germany - 59494

Production of molded parts of rigid polyurethane foam. From individual and on small series up to max. 10,000 units / year. Post-processing on a 5-axis CNC system directly in the house.

Founded

2005

Employees

10 - 20

Certifications

Dierdorf-Wienau

Germany - 56269

Founded

1994

Employees

10 - 20

Certifications

Haag

Germany - 83527

Fa DVM GmbH is a relatively young company in Germany, but has been working for many years already with well-known German and European companies. Our establishment is located in the Swabian Unteraspach (Backnang). Fa DVM GmbH is a competent and reliable partner for the trustful execution of: • QUALITY TESTS • ASSEMBLY • REWORK • ZP / ZFP DESTRUCTIVE TESTING / DESTRUCTIVE TESTING • SUPPLIER MANAGEMENT available. Our wide range of methods and know-how are the basis for the successful and efficient implementation of your (potential) outsourcing projects. DVM company was founded in 2007. DVM company is certified to ISO 9001-2008.

Founded

2007

Employees

20 - 50

Certifications

Aspach

Germany - 71546

Production of bent wire parts and springs from Ø 0.3 - 20 mm using the most modern CNC-controlled systems, multi-slide machines and self-made. Bulk wire articles according to samples or drawings. We use steel, stainless steels, spring steels, non-ferrous metals and alloys as raw materials. From disposable items to 3-dimensional designers - bent parts. From prototype construction to small series to large series. Leg, tension and compression springs. Robot welding parts MIG-MAG-TIG. Spot, projection, stud and butt welding. We punch, press, punch, calibrate on various mechanical and hydraulic Pressing 5 tons. up to 600 tons. Printing performance. Fast moving and deep drawing presses Hanging and painting hooks. Bucket and carry handle. CNC long turned and milled parts up to Ø 16.0 x 4,000 mm Processing such as drilling, milling, thread rolling, wobble riveting, chamfering, butting. Assembly of assemblies, 100% tests, special packaging and handling systems. Own tool shop. External surface processing such as blasting, pickling, anodizing, coating, gold plating, chrome plating, galvanize, KTL coating. Procurement of laser parts and laser welding through our partner companies. Punching and Deep-drawn parts from 0.1 - 5.0 mm sheet thickness and 300 mm sheet width.

Founded

1936

Employees

20 - 50

Certifications

Erkenbrechtsweiler

Germany - 73268

CNC milling contract manufacturing We can manufacture plastic, aluminum, brass, copper, steel, stainless steel and tool steel components using a 3-axis CNC milling machine. Key data Minimum component size: 7 x 7 x 7 mm Maximum component size: 450 x 160 x 150 mm Processing in the uncured state (steels) Prototypes individual parts small series Machining strategies Milling Deburring / chamfering Drill Tapping Reduce Rub Thread milling engraving 3D processing Materials plastic Brass aluminum copper steel stainless steel Tool steel

Founded

Employees

Certifications

Spalt

Germany - 91174

Our company has been operating since 1996 in the field of individual engineering and metal construction. We offer effective solutions for a wide variety of businesses, such as: logistics, transport and packaging methods. Our goal is to have a machine park that is flexible enough to meet the challenges of the market. Through continuous further development, we strive to ensure that our company can always keep up with current quality expectations.

Founded

1996

Employees

20 - 50

Certifications

Balogunyom

Hungary - 9771

We provide comprehensive contract manufacturing services, covering the entire process from simple mechanical component assembly to precise electro-mechanical assembly, functional testing, and the production of highly complex modules and complete machines.

Founded

2015

Employees

10 - 20

Certifications

Kielce

Poland - 25-663

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Series and component assembly Cable assembly Measurement technology environmental, Vibration and climatic test Mechanical machining

Founded

1973

Employees

Certifications

Markdorf

Germany - 88677

Adestra metalworking, flexible modern enterprise, the sheet metal and tube machining, and mechanical machining can offer turning and milling. We design, produce and assemble according to customer requirements: housing, terminals, machines, machine covers, custom solutions, components and assemblies.

Founded

1994

Employees

50 - 100

Certifications

Pilsen

Czech Republic - 301 00

BSA wants to be a point of reference for the Customers who are looking for a serious and professional partnership to fullfill their needs in the sector of sheet metal molded parts. OUR ACTIVITY SECTORS ARE: DESIGN AND CONSTRUCTION OF TOOLS FOR SHEET METAL COLD SHEET MOLDING AND TOOLING ASSEMBLIES OF SMALL COMPONENTS CNC PUNCHING AND PRESS BENDING

Founded

1993

Employees

20 - 50

Certifications

Venaria

Italy - 10078

As a metal processing company, SIBA stands out due to its many qualities. With our comprehensive knowledge, decades of experience and exceptional flexibility, we are able to solve even complex challenges for you. This is how we create trust and lasting satisfaction. As a flexible contract manufacturer, we are fast, imaginative and remain down to earth. We produce your top-quality products within the required time. Our wide range of manufacturing processes gives us exceptional flexibility. We see ourselves as your idea provider, idea implementer and idea developer. We work closely with our customers and find the best solution for every challenge!

Founded

1962

Employees

50 - 100

Certifications

Dillenburg-Frohnhausen

Germany - 35684

Stirline GmbH is your specialist for contract manufacturing in friction stir welding and CNC metalworking, with more than 5 years of experience in industrial FSW contract manufacturing for battery trays, inverter housings, electric motors and cooling applications. With us you get everything from a single source, devices - processes - serial parts! We start with the first sample series, up to the series production of several 100,000 pieces. We weld with 100% data tracking, and our GOM system also ensures our high quality standard. FSW - Ask us!

Founded

2022

Employees

< 5

Certifications

Graz

Austria - 8020