Find specialized suppliers for surface grinding on Techpilot. Our platform offers access to suppliers who use advanced grinding technologies to create precise and high-quality surface finishes. Benefit from comprehensive market transparency and efficient supplier search.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

PREMETEC develops solutions for customer-specific measurement and testing tasks with the necessary upstream or downstream automation steps for our customers. We implement the measuring devices, gauges, assembly systems and systems we supply in-house until they are put into operation. We represent almost all specialist machine construction sectors: from mechanical design to electrical project planning, control cabinet construction, PLC and robot programming (Siemens, Kuka, Yaskawa), parts manufacturing (turning, milling, flat and cylindrical grinding), assembly, commissioning and service. You can find some examples of our products in the link. https://premetec.de/de/leistungen/produkte You can find more applications here on the YouTube channel. https://www.youtube.com/channel/UCvoLYgt6TPaNvzd0Uhh3hEw

Founded

1994

Employees

20 - 50

Certifications

Suhl

Germany - 98527

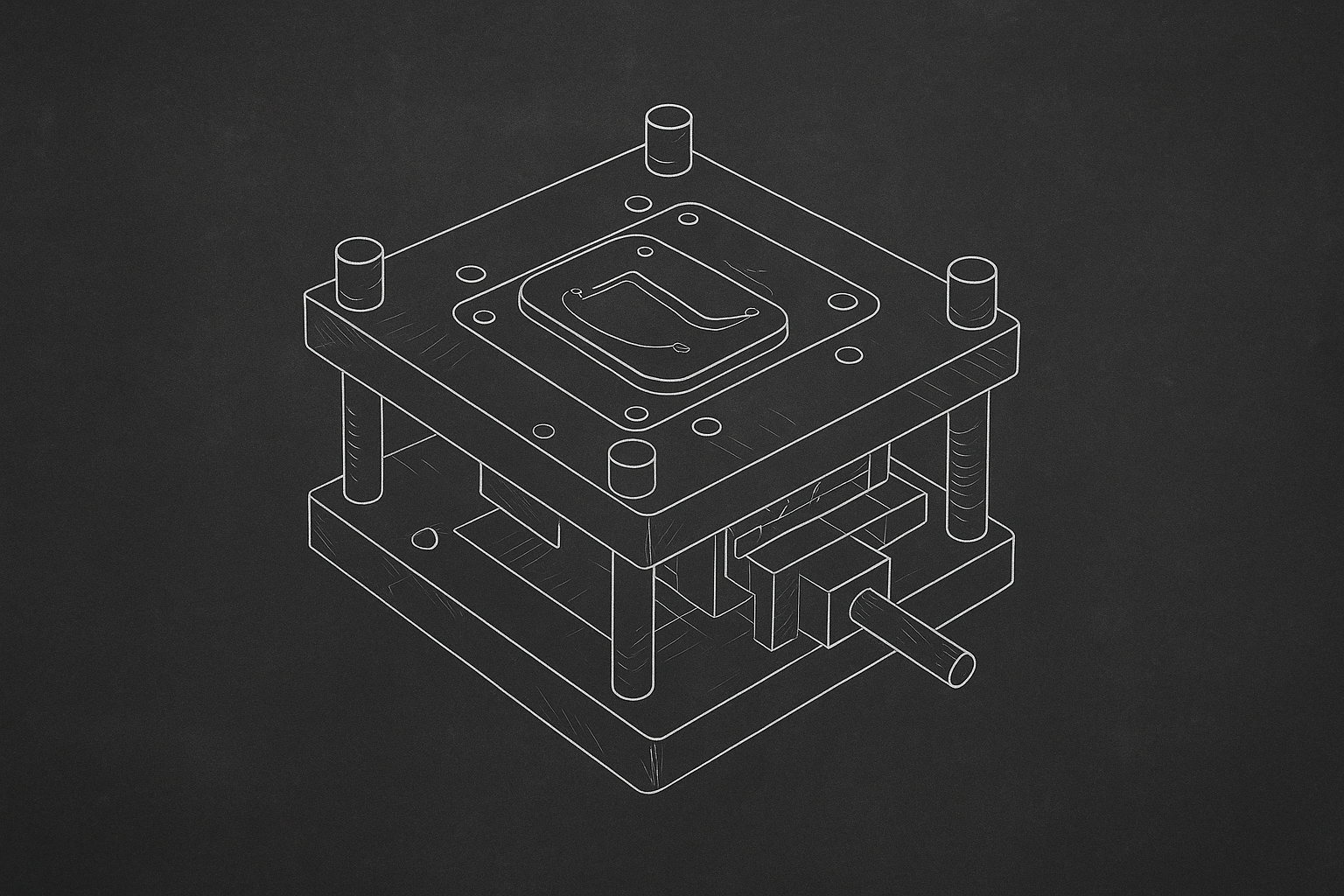

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002

Production and sales of cold forming parts, turning and milling parts. All size ranges and part geometries. CNC single and multi-spindle

Founded

1939

Employees

200 - 500

Certifications

Wuppertal

Germany - 42117

Founded

1985

Employees

< 5

Certifications

Zimmern ob Rottweil

Germany - 78658

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our company offers precision engineering and more from one source. On a modern, computer-aided machine tools we mill prototypes, individual parts and series parts. Using the latest machining centers we work with high precision milled parts up to 5 pages in one setting. This complex machined parts can be manufactured economically. The NC programs are prepared for programming on workstations. We can easily your drawing dxf data in formats dwg, step, igs, vda, sat assume. Materials and work area We process the materials of aluminum, iron, cast iron, steel, titanium, brass and plastic The maximum working range of our machines is 500x500x400 mm Program of delivery Ready for renowned customers from different industries and we edit: Bearing, housing, plates, linear units, assembly units, handling units, grippers, guides, levers, bars, distances, angles, baking, clasps, frames, covers, holders, body, castings, profiles Assemblies Complete assemblies and devices are manufactured by us ready for installation including the given surface treatment and fitted.Our own tool enables the production of stamped and bent parts

in small and medium-sized batches. Through our wide range of possibilities for cutting and non-cutting processing results in a wide range of activities. Our services are completed by: Surface treatments such as Trowalieren, polishing, grinding and sandblasting Surface coatings such as anodizing, chromating, burnishing, nickel plating, etc. Heat treatment processes such as carburizing, nitriding, inductive hardening. Proven Quality All products are subject to during production and before delivery to continuous quality control by our qualified staff to meet our demand for a zero-defect production.

Founded

1922

Employees

Certifications

Pforzheim

Germany - 75175

Oerlikon Barmag is the world market leader in the manufacture of spinning systems for man-made fibers such as nylon, polyester and polypropylene, as well as texturing machines. In addition to plant design and system design and production, the core competencies also include the manufacture of the associated components such as winding heads, pumps and godets. At the headquarters in Remscheid, Germany, over 100 engineers and technicians develop innovative and technologically leading products for the world of tomorrow.

Founded

1922

Employees

500 - 1000

Certifications

Remscheid

Germany - 42897

CNC PRODUCTION Turning, milling (5-side machining), grinding with state-of-the-art machining equipment according to current production techniques. We offer machining and high-precision finishing using different production techniques. Individual one-off production as well as serial production according to customer requirements. METAL AND TOOL MAKING Production of tools for hot forging presses (horizontal), complete new production and regeneration offer ready-to-install solutions. Individual areas of the value chain can be processed here.

Founded

1847

Employees

10 - 20

Certifications

Ortenberg

Germany - 77799

HISTORY The craft business, founded in 1961 by Mr. Johannes Richter Senior, has been successfully continued and expanded by Mr. Peter Richter to this day. Our company has been located in the GADA / Bergkirchen industrial estate since 2009. In 2013 we were able to name Mr. Stefan Frank alongside Mr. Peter Richter as managing director. OPPORTUNITIES With our modern machinery and corresponding know-how, we can deal individually with all tasks. TRAINING OPERATION As a conscientious training company, we are committed to providing information events and offers on site, future-oriented and with social responsibility. EMPLOYEE All of our employees were trained and taken on within our company. In addition, further education and training are carried out.

Founded

1961

Employees

5 - 10

Certifications

Bergkirchen/GADA

Germany - 85232

WHO ARE WE? We are a new and young company specializing in all sheet metal systems, especially laser cutting and bending, edging and laser welding. We are located in the north of Croatia 5 km from the Slovenian border and just as far from the highway which is very important to us makes it easily accessible. We are there to manufacture the requested parts precisely and with a high quality for you We look forward to working together.

Founded

2022

Employees

50 - 100

Certifications

Donji Zebanec

Croatia - 40314

COMPANY PROFILE For over 2 decades, we are now working for you and ensure satisfied customers. We work with a variety of materials in processing apart and have extensive expertise and modern machinery. Our quest is to develop innovative products using functional home materials. Of course, with the highest accuracy. SERVICE For all our products we have, of course, a comprehensive repair service. Procurement of materials and surface finishing of the finished parts, we assume, if desired. Assemblies of assemblies or complete units are no problem for us. We Vibratory grinding, glass pearl - or sandblasting. For more information, please contact us. PRODUCTS Materials We used: - Plastic - Steel - Stainless Steel - Ferrous metal - Inter alia Detailed Description: For our products we use a variety of materials to meet the demands of the customers. We can advise you which materials for the desired product, would be ideal considering the use. It is our concern, already in solving this problem to be your partner and specialist. The post-processing of various materials is not a problem for us dar. Precision milled parts and micro-milled parts made of various materials are no problem for us. Detailed Description: To manufacture our machine park features Milling: • Processing Center "FADAL" with 4 axis 26 tools Weg760mm • Maho 800 E • Maho 600 P • Maho 400 E • 1 hand lever milling machine Precision Gears we produce for you in orders of magnitude from 3mm-250mm diameter, module 0.15 - 5mm in various of materials. Detailed Description: To manufacture our machines include hobbing (Gear): • 2 micron diameter 200mm • 1 Klopfer Ø 150mm • 1 Gauthier Ø 80mm • 1 PFauter Ø 250mm Vices We manufacture Kleinschraubstöcke for laboratories and goldsmiths, as well as to measure of workpieces. From the materials steel, stainless steel and titanium. Detailed Description: Highest accuracy and Vearbeitungsqualität also feature our vices individually produced. With the materials used, steel, stainless steel and titanium durability is guaranteed. Precision Turned Parts we produce for you in all materials with a diameter of 1mm to. Find out more about our extensive editing options. Detailed Description: Our production is not limited to the production of the requested rotation parts. Our services go back to the development and production of finished components. to manufacture our machinery has the following lathes: • CNC Colchester Tornado 80 meters loader spindle bore Ø42mm • Automatic EMI MEC • 2 turret lathes Ø10mm • 4 lathes Ø26mm • 1 guide and Zugspinder Colchester Precision Table Saw RPTK I: the saw for non-ferrous metal 15 x 15mm U / min.1400/2800 RPTK II: the saw for steel 12 x 12mm U / min. 700/1400 • Special accessories available Detailed Description: This small precision saws are the problem solution with many advantages. They are with their different speeds ideal for efficient exact cutting. Additional Operations omitted. The longitudinal stop with clamping lever and micrometer screw is used for the efficient and fast adjustment of the desired finished length of the abzusägenden part. The massive construction (beveled and welded body), as well as precision bearing parts of the nitrided blade shaft and the pivot system allow a saw cut of the highest surface quality. If interested, we will send you detailed info...

Founded

1985

Employees

< 5

Certifications

Eisenberg

Germany - 87637

Founded

2016

Employees

< 5

Certifications

Manisa

Turkey - 45030

The Kurt Schneider AG is a mechanical operation in the field of production and module assembly. Our products range consists of the complete manufacture of individual parts to series production. We can manufacture simple to highly complex products of any materials.

Founded

1973

Employees

20 - 50

Certifications

Thun

Switzerland - 3608

We are a Netherlands based company producing goods in Asia. We have been in Asia for 20 years and specialise in many custom made parts for our clients in Europe. We have technical staff in China locally, including European managers and a wide array of suppliers giving us the ability to provide our customers with a variety of parts. We specialise in hot-forged and casted items but are also strong in sheet metal, turning and milling. Our warehouse is located in Veldhoven, The Netherlands here we stock goods for our customers so we can always supply our goods on-time. We also have some of our own CNC milling and lathing equipment in The Netherlands where we produce smaller quantity items for our customers. We have experience in different fields and are able to work with standard procedures such as PPAP level 3 and 8D when solving SCAR's from our customers. We have experience in the automotive industry and are capable in adhering to the required standards, We look forward to meeting you in Veldhoven or at your business and creating a mutually beneficial relationship!

Founded

Employees

5 - 10

Certifications

Veldhoven

Netherlands - 5508RN

The company was founded in 1949 by Hauke Walter Hauke sen. founded. The company has set itself the target to process all kinds of metal. Made of iron, steel, stainless steel, aluminum, copper and brass welding complicated constructions and pipe bending constructions are made. The material undergoes metal with us from the mechanical machining to surface treatment is a proven program. This production range assumes, of course highly qualified and motivated employees and a large, high-quality machinery. Our company philosophy, "quality at a very reasonable price" has proven itself for over 50 years. Our customers, who are party to all industries, come from all over Germany. Take a picture of us - look!

Founded

1949

Employees

20 - 50

Certifications

Göppingen

Germany - 73037

Foundation Established in 1994, we mainly manufacture today for the steel plant and •. Our team consists of 12 specialists from various fields. Divisions: • Drehtechnik • Welding Technology • Flame cutting • Plasma cutting • cuts on plate shears or saw • Rollers • Bending • CNC turning • CNC Milling • Welding TIG, MIG, MAG • Machining • Milling Grind Cylindrical grinding • Max. D400 x 1500 Sheet metal & steel construction • Bending • Cut • Welding • Rollers

Founded

1994

Employees

10 - 20

Certifications

Homburg (Saar)

Germany - 66424

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

GTS Gate To Steel GmbH is a German company based in Düsseldorf. We are based in the field of mechanical and plant engineering. Our subsidiary is located in Wuxi near Shanghai. We have been in our line of business in China since 2004. We know the market and business inside and out. Our customers are German companies that sell industrial equipment to China. We are not an intermediary! GTS produces itself in its own hall. GTS takes over the production of the local production portion in China for the customers. We manufacture both entire assemblies and individual parts - it only depends on the needs of our customers. Of course we can also take care of the transport to Europe and all related formalities. We stand for: German quality made in China Know-how protection Customary market prices On-time delivery Our highly qualified team in our own assembly hall, together with a proven network of sub-suppliers, form your extended arm in China. Together they realize your projects in your usual German quality. GTS offers you an all-round carefree package tailored to your requirements.

Founded

2015

Employees

10 - 20

Certifications

Düsseldorf, Wuxi

Germany - DE-40223, CN-214185

Our family is in the 4th Generation and has 2 legs. Technical marine equipment and sheet metal processing. Due to the marine equipment we are used to respond flexibly and quickly. Our manufacturing capabilities are: - Punches up to 80t - Tieftiehen up to 100t - Lasers (ST to 25mm; VA to 12 mm, aluminum up to 8 mm) - Edge- - Welding - Roberterschweißen - (Rice Roborics) - Own tool - Solder - Rivets - Trowalieren - Degreasing

Founded

1881

Employees

20 - 50

Certifications

Reinbek

Germany - 21465

Kiffe surface grinding - lapping, fine grinding, flat grinding, flat honing, polishing, double face grinding, cleaning, laser marking, Flatness measurement, complete machining. For rush orders also Preferred processing.

Founded

1985

Employees

10 - 20

Certifications

Villingen-Schwenningen

Germany - 78048

We want to introduce ourselves to your company as a highly capable suppliers and partners who can offer the best solutions for your particular tasks and problems in trusting cooperation. Our company acts as a supplier for cubic components, turned parts and assemblies since 1999. Compliance with the required quality and the desired delivery of the highest priority. After moving in the summer of 2007, since then we are 900 square meters of production space. Currently we manufacture 14 CNC turning and CNC milling machines in three shifts. For future changes, there is still significant Erweiterungspotenial at a plot size of about 5000 square meters. To utilize our manufacturing capacity as possible, we are in search of work, starting with conventional lathes and milling operations from the machine-cutting through to the production of complete assemblies ready for installation and complete solutions. From the single-part production on small to large series are us in connection with our system partners, virtually the entire range of manufacturing options available, especially in the diameter range up to 150 mm. We look forward to your inquiries and assure you receive today a timely and reliable processing to.

Founded

1999

Employees

20 - 50

Certifications

Altdorf

Germany - 90518

Cramer Schleiftechnik not only grinds, modifies, repairs and coats existing cutting tools, but we also manufacture special tools according to your needs and specifications, which are not yet available on the market. By professionally regrinding, coating or repairing cutting tools, you can significantly extend the useful life of tools and thus save considerable costs. With special tools specifically tailored to your production, it is often possible to combine several work steps. In addition to cost savings, this often results in shorter production times or higher production volumes in the same time compared to several steps with standard tools. With all our services, we clearly focus on your wishes and needs and react flexibly to changes or special requirements. Precision, quality and on-time delivery are a matter of course for us in all services.

Founded

1975

Employees

10 - 20

Certifications

Mönchengladbach

Germany - 41238