Find specialized suppliers for deep hole drilling on Techpilot. Our platform offers access to suppliers who use advanced drilling technologies to create deep and precise holes in materials. Benefit from comprehensive market transparency and optimize your supplier selection.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

© MerCell GmbH I CNC - manufacturing technology 2013 I Conditions of Use Manufacturing turned parts we manufacture up to a diameter of 300 mm and a length of 640 mm. About power tools Here is the possibility of complete machining of components - eliminating the need for set-up costs of an additional engine Translation by Google Translate

Founded

1997

Employees

5 - 10

Certifications

Hanau

Germany - 63456

We are manufacturers of gas valves, DIN DVGW approved Extract products: - Steel ball valves in Duchtgangs- and angle versions, many connection types, including insulating - Thermal shut-off / TAS / TAE / TGSA - Insulating - Steel-PE connectors for gas and water - All components are in steel or stainless steel, also connections to customer Contract work: turning, milling, drilling, welding, assembly

Founded

1991

Employees

5 - 10

Certifications

Erndtebrück

Germany - 57339

The MBM Lychen GmbH is your competent partner for the manufacture of machinery parts in the installation qualities (IT 6 and IT 7) as well as the assembly of modules. We work on prototypes, single parts and series in all sizes and provide a job shop machine fixtures forth according to your technical drawings. In addition, our company sees itself as a "fire brigade" in case of damage to machinery and equipment. That is, in an emergency, we do your orders within 24 or 48 hours. The MBM Lychen GmbH has all the machinery and equipment for cutting shaping of the classic built-in components of all kinds. With the support of reliable partners we are further able to your needs in the areas of heat treatment, surface finishing and coating edit technology and sheet metal work in full. The following materials we process with our modern machinery: - Non-ferrous metals (aluminum, copper, brass) - Hot and high-strength steels, - Construction and quality steels, - Hardened and tempered steels, - Tool and nitriding, - Stainless steels, - Cast iron, - Nickel and titanium alloys, - Plastics

Founded

1991

Employees

20 - 50

Certifications

Lychen

Germany - 17279

The company was founded in 1961 by Mr. Roland Smith in Untersteinach. Within the framework of an asset deal, the company IK Blacksmith GmbH has bought the company on 01/05/2014. At the company's site in 95369 Untersteinach about 40 skilled workers work on modern and high-precision CNC lathes, grinding, milling and EDM. We produce individual parts and small series as well as special machinery parts and special clamping tools according to customer requirements. Our customers are global engineering industry and automotive suppliers.

Founded

1961

Employees

20 - 50

Certifications

Untersteinach

Germany - 95369

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

CHODOS CHODOV s.r.o. is a medium-sized machinery company, employing 170 people. The main production program includes machine production for rubber and plastic industry. We follow and develop the brand history and tradition of CHODOS. The company has its own design and technological department and production base for development and production of own products in machinery. CHODOS disposes of management quality certificate according to the standard ISO 9001 and ČSN EN SO 3834-2 for welding processes. - design, development, production and servicing of machines for the rubber and plastics industry - design, development, production and servicing of machines and machinery - production of compact heat transfer stations - machining, heat and chemical-heat treatment and plating of components

Founded

1883

Employees

100 - 200

Certifications

Chodov

Czech Republic - 35735

We are a young company based in Baden-Württemberg, we have been working in the Brace for 2 years. Machinery: Two 3-axis milling machines, a CnC lathe with 3m bar feeder diameter up to 42mm. a CnC lathe with 3 jaw chuck span width up to 250mm. a saw

Founded

2020

Employees

< 5

Certifications

Boxberg

Germany - 97944

The company HSR Speckhahn has been anchored on the market and in the region for over 60 years. Our 35 qualified employees are in the field of steel construction, mechanical processing with CNC-controlled machines and in technical industrial service for our customers. Mechanical machining - Turning, milling, drilling, grooving on CNC controlled equipment Welding operation special constructions industry service

Founded

1954

Employees

20 - 50

Certifications

Radenbeck

Germany - 29378

ZS Zylinderbau & Service has been planning, designing and manufacturing large and special hydraulic cylinders for industrial customers, mobile machines and hydraulic steel construction for over 20 years. Thanks to the high level of vertical integration (turning, milling, drilling, deep hole drilling, grinding, honing, welding), we can also carry out extensive repairs of third-party products if required.

Founded

Employees

20 - 50

Certifications

Xanten

Germany - 46509

As a specialist for special and precision turned parts in the field of turning, milling and grinding parts, we serve clients in the areas of aerospace, Automotive, electrical and drive systems operate. Other customers of Pneumatics, hydraulics and connection, high frequency and Medical part of our long-standing customer base. The machining of aluminum, plastics, carbon and vending machines and hardened steels represents for us no problems In particular, we can nickel - chromium - alloys and stainless steels and heat resisting steels in smaller and medium quantities manufacture for you. Also materials from the aerospace industry can be edited with our machinery. Of course, we are also certified according to DIN EN ISO 9001:2000. In addition corresponds to our quality management system the requirements of the Federal Association of the German air and space industry and has been audited by QSF-B (EN 9100).

Founded

1937

Employees

50 - 100

Certifications

Waldkirch

Germany - 79183

Production and sales of cold forming parts, turning and milling parts. All size ranges and part geometries. CNC single and multi-spindle

Founded

1939

Employees

200 - 500

Certifications

Wuppertal

Germany - 42117

TCM Germany is a subsidiary of TCM International GmbH. The headquarters of TCM International GmbH are in Stainz (Austria). In addition to numerous holdings, it has branches in Germany, Luxembourg, Poland, the Czech Republic, Hungary, France and China. As an innovative technology partner in machining production, the TCM Group offers a diverse portfolio of services. This ranges from the tool trade and output systems of the “TOOLBASE” brand to the complete, productivity-oriented TOOL MANAGEMENT service. In order to be able to support TCM customers even better and to meet modern requirements of "Smart Production", the company WinTool with the tool management software of the same name is one of the cornerstones of the TCM Group. The TCM company portfolio is rounded off by its own training program in which technical expertise on machining processes and their environment is imparted in a modular and manufacturer-independent manner.

Founded

1996

Employees

500 - 1000

Certifications

Gladbeck

Germany - 45966

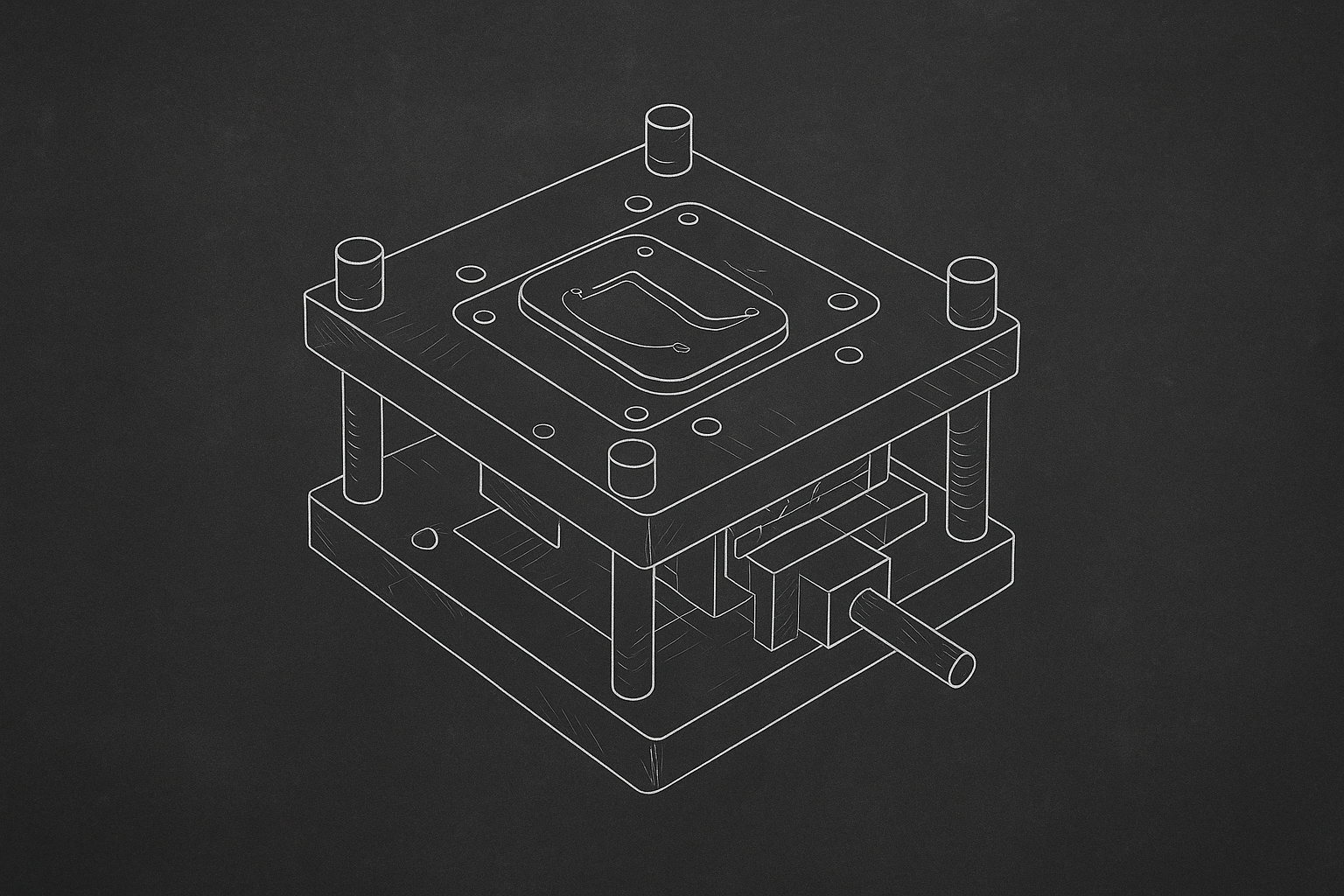

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002

VENDOM SRL has been supplying turned parts in various alloys such as aluminum alloys, cast aluminium, stainless steel and brass, bronze, special alloys, etc. for over 20 years. Our company has a wide range of machines and can therefore produce both small and large series. We guarantee our customers professionalism, competence and quality.

Founded

2006

Employees

< 5

Certifications

Brescia

Italy - 25128

Manufacturer of attachment tools for Baumschinen

Founded

1997

Employees

10 - 20

Certifications

Goldenstedt

Germany - 49424

BMmetal is an industrial unit specialized Machining (Turning & Milling) . A member of the B&M group , it offers its company a wide range of services, always striving for Rigor and Quality in each product it produces. Operating from the municipality of Óbidos, we work for the whole world. We are prepared, both in technical equipment and in specialized human resources, to carry out work with any type of metal in order to materialize each project. Our focus is always the specifics requested by each client. All the raw materials used are chosen for their quality, in order to ensure a high quality finished product.

Founded

1997

Employees

100 - 200

Certifications

Óbidos

Portugal - 2510-752

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Top performance and innovative power right from the start. The company, founded in Bavaria in 1959, initially mainly manufactured electrical switchgear. In 1971 the development and production of electrical equipment for drawing machines and winders started. Complete machines and accessories for the wire and cable industry have been manufactured since 1984. In 1997, an additional second production and administration building in Vohenstrauß could be occupied. The new plant 2 is located 7 km from the main plant in Albersrieth. Furthermore, in 2020 the manufacturing portfolio was expanded to include contract manufacturing in the following areas: Laser cutting, edging, welding, milling and turning, We have decades of experience in the manufacturing processes thanks to our mechanical engineering. We currently employ over 90 people and the trend is rising.

Founded

E263157807

Employees

50 - 100

Certifications

Waldthurn/Opf.

Germany - 92727

As leading experts in tool making, we distinguish ourselves through our expertise in cold and hot forming. We offer our customers reliable toolmaking solutions for high-strength and ultra-high-strength steels, aluminum forming and carbon products that are tailored exactly to their individual needs. Mechanical processing at weba Werkzeugbau stands for maximum precision and innovation. With our versatile machinery and decades of experience, we manufacture your components in the field of mechanical, plant and tool manufacturing — whether small parts, medium size or large part processing. Machine park: over 30 milling machines Products: Manufacture of workpieces in any shape with high precision using 5-axis milling machines Maximum processing dimensions: 8,000 x 3,100 x 1800 mm Indoor cranes: up to 25 t Precision: accuracy of +/- 0.01 mm is possible Programming: Creation of CNC programs by in-house programming department using Esprit and WorkNC Data formats: CATPart, CATProduct, DWG, DXF, Siemens NX, STEP, IGES, VDA

Founded

1982

Employees

200 - 500

Certifications

Dietach

Austria - 4407

SOBEK CNC manufactures ready-to-install turning, milling and drilling parts as individual parts or in small and large series from all machinable materials with or without surface treatment. With our modern and powerful machine park, we are optimally equipped for the production of sophisticated turned and milled parts. We are happy to support you in the product development stage and thus enable the cost optimization of your components right from the start. Processing methods outside of our production range, e.g. B. grinding, laser marking, heat treatment, gear cutting, polishing, electropolishing, anodizing, nickel plating, galvanizing, chromating and passivating are carried out by long-standing and trustworthy cooperation partners - we take care of the timely organization.

Founded

1985

Employees

5 - 10

Certifications

Karlsdorf-Neuthard

Germany - 76689

Our competence in consulting and manufacturing is built on years of experience as well as modern technology and makes us an estimated development partner for well known companies for engineering and plant construction. Sice the foundation in 1948 Lenser Praezisionstechnik has sucessfully developed into a leading independend provider of heating and cooling plates in Europe. Meanwhile we have been specialized in high precision machining of large metal surfaces for decades. For decades we have specialized in the production of heating and cooling plates for hydraulic presses. Our experience in this field has made us the leading provider in the European Market independent of the press manufacturer. Such plates are used in the wood-working industry for the production of chips- and fibre boards, for sports equipments as well as for the surface processing of doors, furniture components and timber products. In the field of laminating and multilayer components such plates are used in card presses and for the production of printed circuit boards. The Rubber goods industry uses our plates for the heating of vulcanising moulds and the production of conveyor belts. Our heating and cooling plates are exclusively designed product-related on customer request and manufactured as individual units. Our delivery program includes plates of dimensions up to 16.000 mm in length, up to 3.700 mm in width and maximum weights of up to 100 tons per unit. 01 Our pressing moulds are mainly used by the manufacturers of semi-finished products for the grouting of thermoplastics (e.g. PP, PE, HDPE). They are also used for producing filter elements made of propylene or similar materials. Indirectly Heated Pressing Moulds consisting of – basic plate – cover plate – movable frame parts. Gasic and cover plates are indirectly heated or cooled by the contact heat of heating plates. Frame parts are directly heated or cooled by corresponding mediums. Directly Heated Pressing Mould consisting of – basic heating plate – cover heating plate – movable frame part. The basic heating plate and the cover heating plate as well as the frame parts are directly heated or cooled by corresponding mediums. As an experienced and competent partner we offer customized solutions for dimensions up to 10.000 x 3.000 mm.

Founded

Employees

50 - 100

Certifications

Senden

Germany - 89250

“Our roots in toolmaking — your future in contract manufacturing” We have been specialists in punching tools for many years — precision and quality are our DNA. On this basis, we are taking the next step: From now on, we will also take over your contract manufacturing. Whether prototype, small series or series production — you benefit from our specialization in toolmaking and from a partner who understands manufacturing down pat. Rely on proven experience — in punching tools and contract manufacturing.

Founded

Employees

< 5

Certifications

Rhauderfehn

Germany - 26817