Find specialized suppliers for turning on Techpilot. Our platform offers access to suppliers who use advanced turning technologies to manufacture precise and customized parts. Benefit from comprehensive market transparency and optimize your supplier selection.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

The azw is a reliable partner for the settlement of commercial work. A dedicated team of production staff and learners produced for you to advanced machinery and equipment. In the highest quality and on time and at competitive prices, we carry out your order.

Founded

2002

Employees

50 - 100

Certifications

Winterthur

Switzerland - 8401

Frez Projekt provides services in the scope of comprehensive metal and plastic processing with the use of CNC machines. Our knowledge and many years of experience is what enables us to successfully execute even the most difficult tasks. We cooperate with companies operating in many lines of business, including automotive, medical, food or construction, which enables constant development and increasingly better adjustment to the needs and requirements of clients, including the most demanding ones. We manufacture singular small items, as well as small and medium product series. Our main assets are the following: • high quality of product and attention to details • comprehensive services, including designing • short delivery dates • our own transport

Founded

2013

Employees

5 - 10

Certifications

Krzymow

Poland - 62513

Founded

Employees

5 - 10

Certifications

Frankenberg

Germany - 09669

we, as elzem technical metal, are a company operating in the machining and cutting tool sales sector. We are serving in the machining sector with our cnc lathe, cnc milling and sliding head machine.

Founded

Employees

5 - 10

Certifications

ÇEKMEKÖY

Turkey - 0(553) 684 49 52

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Today Centrometal d.o.o. persistently is underway to become a leading Croatian thermotechnical equipment constructor. Accent at development is pointed to the equipment which use renewable energy sources (wood, pellets, wood chip, sun…) thus the company is actively involved in protection of the environment and effectively use of energy.

Founded

1965

Employees

200 - 500

Certifications

Macinec

Croatia - 40306

Since 1988, Steel Lavorazioni Meccaniche has been manufacturing medium to large mechanical components through high-precision machining. The multisectoral approach and the long experience on the multiple types of materials make us the market leader. The company is headquartered in Motta di Livenza, in the province of Treviso, where our large fleet of machines allows for high specialization in: ●Milling ●Turning ●Deep drilling ●Water cutting ●Tangential adjustment We are specialized in the production of plates for the production of PET preform molds and we have a solid and heterogeneous customer portfolio. In fact, we produce a wide range of products for multiple sectors including •Aeronautical •Food •Automation •Packaging •Recycling •Nuclear Our machine park consisting of 44 work centers allows us to guarantee certain and competitive processing times, maximum quality and precision even in large components up to 6 meters in length. The meticulous checks in the metrology room ensure the quality of the production processes and ascertain the dimensional correspondence of the pieces produced. In 35 years of experience, we have become a leading company in the sector. We support our customers with know-how and innovative technologies to offer a complete service that ranges from the selection of materials to technical construction support for the choice of the best construction solutions. Thanks to the experience gained in collaboration with WRS Waste Recycling System, our partner company, we can also create pre-assembled mechanical groups with the parts produced in our workshop. Our quality system meets the most advanced standards and guarantees tracked, controlled and replicable process management. Steel Mechanical Processing is also certified according to the strict requirements required by the specifications of the aerospace and nuclear industry.

Founded

1988

Employees

20 - 50

Certifications

Motta di Livenza (TV)

Italy - 31045

P&M tools construction is a young company that was founded in 2018 by two mechanical engineers with many year od experience. The company was founded to offer the market new conceptual solutions, as well as to contribute to the development of the auto and machine industry. In addition, we deal with tool making, modeling and programing. We offer welding of complex assemblies as well as laser cutting of materials.

Founded

2018

Employees

5 - 10

Certifications

Kragujevac

Serbia - 34000

The company started in 1990. as a workshop for production and repair of brake cylinders, and today we operate as a company in product development and production of parts made of polymer and metal materials.

Founded

2022

Employees

5 - 10

Certifications

Vrbovec

Croatia - 10340

RUPREC Industries is a company specialized in high-precision CNC machining (3 and 5 axes), turning, EDM, certified welding, mechanical assembly, and dimensional control. With a strong focus on quality, precision, and innovation, RUPREC operates in the aerospace, electronics, pharmaceutical, food, and packaging sectors, providing high-performance technical solutions. With a presence in Portugal, Spain, France, Germany, and Switzerland, the company stands out for its responsiveness, flexibility, and commitment to excellence in every project.

Founded

Employees

20 - 50

Certifications

TROFA

Portugal - 4785

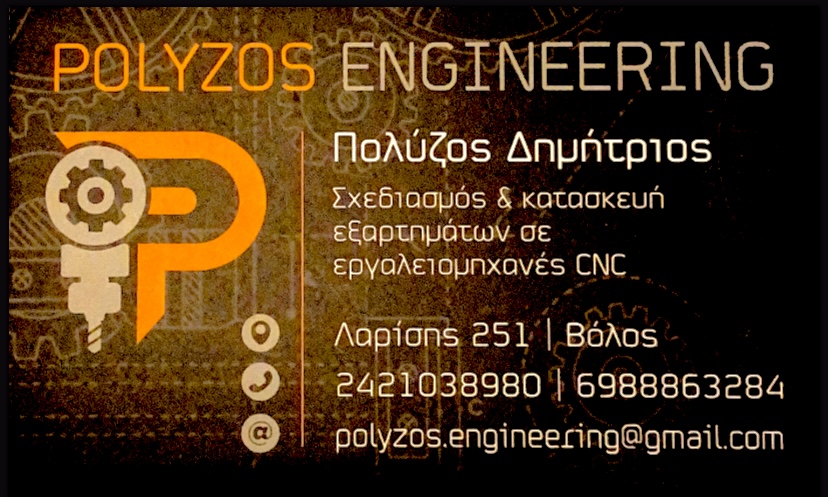

Polyzos Engineering is a leading CNC machine shop that manufactures high-quality parts for local industries. With expertise in creating custom parts from designs or samples, we ensure precision and durability. Our specialization in repairs and reverse engineering allows us to provide tailored solutions for complex mechanical challenges. Committed to innovation and excellence, Polyzos Engineering leverages advanced technology to meet the unique needs of each client. Experience reliable service and exceptional craftsmanship with us. Choose Polyzos Engineering for all your CNC machining requirements.

Founded

1978

Employees

< 5

Certifications

VOLOS

Greece - 38445

Ciemme 80 is an Italian company based in the Emilia-Romagna active. We operate in machining. With over 30 years experience in the field of metalworking, Ciemme 80 manufactured according to customer demand high-quality turned and milled parts in all materials. Are manufactured items, smaller series, prototypes and complete modules especially for industries automation, mechanical engineering, automotive industry, metallurgy, beverage, and pharmaceutical industries. The company sees itself as a system supplier. Ciemme 80 has in addition to traditional machines with the latest CNC technology to 5-axis machining as well as a powerful CAD / CAM system (SOLIDWORKS / SOLID CAM). Various other services such as surface treatments, heat treatments, electrical discharge machining, gear cutting, grinding or other machining operations do not pose a problem Next Korresp.: en Enquiries to: CIEMME 80 srl, Uta Wetzler, Via Monte Bianco 29, 41042 Fiorano (MO), Mobile: +39 340 6019533, E-mail: wetzler@ciemme80.it, Office. Tel +39 0536 843490, www.ciemme80.it

Founded

1980

Employees

10 - 20

Certifications

Fiorano Modenese

Italy - 41042

We manufacture using the latest technology in the field of CNC turning technology. In a lively exchange with the various industries constantly new parts are added to the product range and made appropriate investments in the production stations. We manufacture highly precise, just in time both small and large quantities with quality, price and service come first with us.

Founded

1964

Employees

20 - 50

Certifications

Leopoldshöhe

Germany - 33818

Founded

2017

Employees

200 - 500

Certifications

Augsburg

Germany - 86153

KML Precision Machining GmbH offers a wide range of services in the field of manufacturing technology. Since 2013 we have acted as a manufacturing partner for technologically sophisticated manufacturing parts all materials. In addition to mechanical processing, surfaces, heat treatment and partial assemblies can also be offered. Production of precision individual and serial parts Production of assemblies (including assembly and measurement protocol) Complex 3D and 5-axis milling operations in all materials freeform surfacing eccentric parts cam making All common data formats (e.g. step, iges, Pro/E, dif, Catia V5, etc.) can be processed to transmit the article data.

Founded

2013

Employees

20 - 50

Certifications

Wien

Austria - A-1100

We are a young, dynamic company and manufacture products made of steel and stainless steel, using separate production areas. We meet the requirements of EN1090 -2 in EXC 2 and ISO 3834 3. We produce welded structures on a production area of around 800m².

Founded

2024

Employees

< 5

Certifications

Bad Aussee

Austria - 8990

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Allweier is a family-owned company, established in 1970 by Hubert Allweier and his wife Edith Allweier. Since then, the company has continuously grown up. Currently, the production space available amounts to 6,500 sq. m and will soon be further extended. At our site, we currently employ 180 employees and 16 apprentices.

Founded

1970

Employees

200 - 500

Certifications

Überlingen/Bodensee

Germany - 88662

NEW The way ahead for 2012; Plogsties improved competence and service plan – read more. -------------------------------------------------------------------------------- Our product range comprises of all types of press components, turned components, and stamped components. With high precision certified quality. We specialise in the production of both individual requirements to mass-volume production of engineering drawings, with sub-assembly specification. Of: screws, nuts, hexagon bolts, pins. axles, rivets and washers. With prototype technical release procedures according to VDA & PPAP. We supply all materials, surface coating, electro-plating, and heat treatments. Implementing additional DIN testing with gage feasibility certification. We deliver worldwide in licence with MAThread™ special screws. As a world wide supplier with more than twenty years expanding experience we have reliably served the following industries. Auto, ship, and aircraft, fork lift trucks, escalators and lift manufacturing. With continuing focus to electronic and machine manufacturing development

Founded

1983

Employees

50 - 100

Certifications

Reinbek

Germany - 21465

Our family business founded in 1954, can look back on a long tradition of successful development and production of extruded parts. With the use of advanced technologies, we now offer cost-effective Kaltformteile of the highest quality and strength. It set us high manufacturing strength, innovative developments and energetic, strong partnerships with the most long-standing customers. are impeccable quality, reliability and intensive, solution-oriented advice on our part based on the trust of our customers. The customer satisfaction, combined with a trustful cooperation of our highly skilled staff, ensures our long-term success. -Strangpressen -Fließpressen

Founded

1954

Employees

50 - 100

Certifications

Remchingen

Germany - 75196

The company RWGrass GmbH is in the range of CNC precision turned and milled parts and finishing of cast and sintered parts at home. Our products are manufactured in various materials and various sizes from small to large series. Our flexibility refers not only to batch sizes from 500 to 100,000 pieces - the adaptation to customer requirements using CAD are appreciated by our partners. The manufacture and assembly of precision mechanical devices and modules is our specialty. Presses, punching, squeezing, riveting, drilling, threading, screw, solder, tin, merge, shapes, spot welding, grinding, milling, turning, adjust, measure and test the purchase of integrated operations. The house tool makes us independent and allows for maximum on-time delivery. So workflows are optimized and customer requirements into account even better. Products: We manufacture turned parts: - Diameter from 8mm to 650mm - Length up to 200mm Milled parts: - Length up to max.800mm Materials: Stainless steel (eg 1.4301, 1.4404,), steel, brass, copper, aluminum, plastics Delivery program: Pump body housing, valve body, piston, adapters, bearing chock, collets, bushings, grips, power tap, shielding, solder lugs, optics carrier photodiode holder, spacer sleeve, stop in connector, female, fiber filters, sleeve, guide pin twist mechanism, driver twist mechanism, thumbwheel mechanics, different door- window buttons, different door window handles, press rings with slope, reference upper part, orientation completely, burner housing, hollow shafts, bolts, lever cylinder housing, shaft for drive motor, cap for drive motor, ball valve, sleeve, guide shaft, stop bar, assembly photographic technique, component assembly Motor snowmaking equipment , component assembly for medical and measuring equipment of human blood analysis;

Founded

Employees

10 - 20

Certifications

Vahrn

Italy - 39040

Founded

Employees

< 5

Certifications

Gaißach

Germany - 83674