Get CNC milled parts from verified suppliers on Techpilot. Our platform connects buyers with manufacturers offering precise and customized CNC milled components. Use the e-sourcing process to save time and costs.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

ARG Metinātava is always open to new collaboration opportunities and is interested in projects requiring high-quality, customized metal solutions. We are ready to offer our expertise, profes-sional team, and certified production capabilities to bring your ideas to life and ensure out-standing results. Our team consists of certified welders performing TIG, MIG, and MAG welding, ensuring the highest precision and quality in every project. ARG Metinātava holds EN 1090 certification, guaranteeing European-level quality, and complies with ISO 3834 standards, demonstrating meticulous production process control and professional welding practices. Our mission is to provide clients with reliable, durable, and precise metal solutions, tailored to individual requirements, while maintaining top-quality standards for both local and European markets.

Founded

Employees

5 - 10

Certifications

Olaine

Latvia - LV2114

Founded

Employees

< 5

Certifications

Elmshorn

Germany - 25335

Founded

Employees

20 - 50

Certifications

Tartu

Estonia - 50412

Founded

2024

Employees

5 - 10

Certifications

Wuppertal

Germany - 42287

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

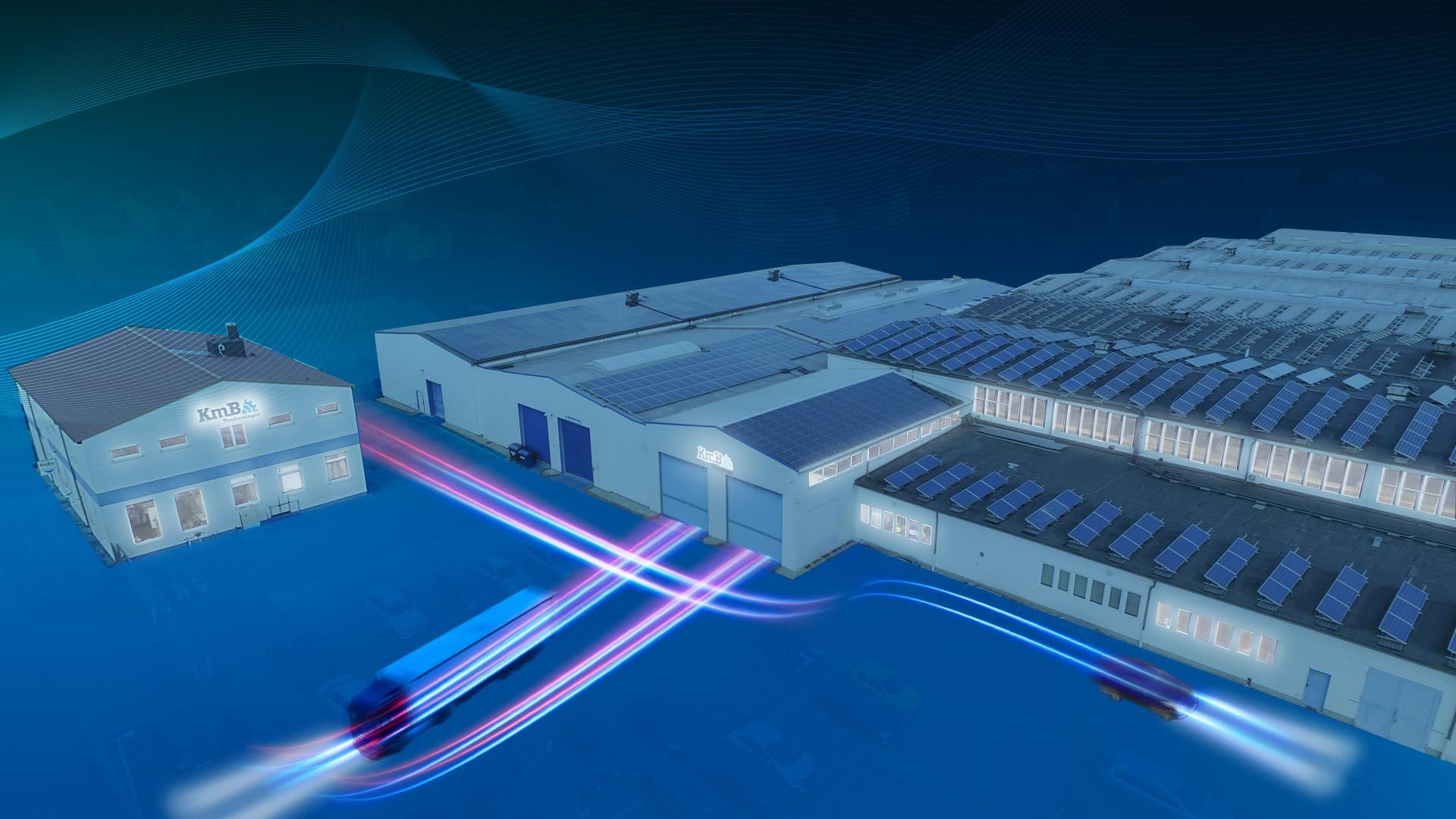

As a “turner”, KmB was founded in 1995 and is today one of the most renowned automotive suppliers in Saxony-Anhalt. Our high-precision turned and milled parts are used in steering systems, transmissions and chassis from various automotive manufacturers. Through a variety of cutting and chipless processing technologies, we create sophisticated automotive components in small and large batches — semi-finished or ready for installation, digitally connected across the entire supply and value chain.

Founded

1995

Employees

100 - 200

Certifications

Zerbst

Germany - 39261

Founded

2021

Employees

5 - 10

Certifications

Dimitrovgrad

Bulgaria - 6400

We are engaged in the production of individual and serial parts in the field of machining

Founded

1956

Employees

10 - 20

Certifications

0 Salzburg

Austria - 5020

MDG International d.o.o. is a premier provider of precision-machined production components, serving a wide array of industries since our inception in 2012. Our unwavering commitment to quality and excellence defines our approach to manufacturing and client service.

Founded

2012

Employees

50 - 100

Certifications

Vogosca

Bosnia & Herzegovina - 71320

Founded

Employees

10 - 20

Certifications

kacarevo

Serbia - 26212

KRÄMER+GREBE is a market leader in developing, designing and manufacturing moulds and tools for demanding castings – from the prototype to the production series. The company specialises in finding solutions to complex geometries and particularly stringent requirements for the properties of castings, and is a recognised partner to the international automotive industry and to foundries across the world. Over many decades we have developed innovative solutions in areas such as grey-iron and light metal casting for the high-pressure-die-casting, permanent-mould-casting and sand-casting processes. For more then 100 years the family-run KRÄMER+GREBE company has stood for experience, passion and extensive know-how.

Founded

1922

Employees

50 - 100

Certifications

Biedenkopf

Germany - 35216

With more than 35 years of experience, PENCOM provides global manufacturing services that combine state-of-the-art technology, engineering expertise, and efficient supply chain management. Our worldwide network of manufacturing facilities and distribution centers ensures on-time delivery, optimized production costs, and consistent high-quality parts. Core Services & Specialties Precision Machining & Metal Forming CNC Machining: Precision parts with complex geometries, tight tolerances, and versatile materials like aluminum, steel, brass, and plastics. From prototyping to production. Metal Stamping: High-speed progressive stamping, custom tooling, and consistent quality assurance for intricate metal components. Automatic Screw Machining: High-speed production for precision-turned components, optimized for cost-efficiency and tight tolerances. Molding & Casting Solutions Plastic Injection Molding: Durable parts using thermoplastics and engineering-grade resins. Includes insert molding for hybrid components and flexible production runs. Die Casting: Lightweight, corrosion-resistant aluminum, zinc, and magnesium parts with close tolerances and automated, high-volume production. Insert Molding: Integrating metal and plastic for hybrid components, streamlining assembly. Fastener & Component Manufacturing Cold Heading: Efficiently produce strong, high-integrity fasteners and specialty hardware with minimal material waste. Assembly Services: Combine molding, machining, and fastener integration to deliver ready-to-use products with reduced lead times. Finishing & Quality Assurance Secondary Services: Surface treatments like plating, anodizing, and painting to enhance aesthetics and durability. Post-Processing: Tapping, deburring, polishing, and more to refine components. Quality Control: Advanced inspections ensure every part meets specifications. Industries We Serve PENCOM’s manufacturing solutions cater to a diverse range of industries, each with unique requirements for precision, reliability, and cost-effectiveness: Automotive: Engine components, electronics housings, interior parts. Aerospace & Defense: Lightweight, high-strength parts built to stringent quality standards. Medical & Healthcare: Biocompatible plastics and metals for durable, precise components. Consumer Electronics: Compact, high-volume parts with fine detail. Industrial & Automation: Robust mechanical parts for assemblies and factory machinery. Energy & Utilities: Corrosion-resistant materials for harsh operating environments. PENCOM’s Quality & Engineering Support ISO-Certified Systems: Our facilities follow recognized quality standards to ensure consistency in every batch. Advanced Equipment & Technology: CNC machines, automated presses, and high-precision tooling deliver reliable results. Design Optimization: Work with our engineers to reduce material usage, simplify part design, and improve product longevity. Prototyping & Testing: Validate part performance and refine designs before committing to full-scale production. Dedicated Project Management: A single point of contact for streamlined communication and timely updates.

Founded

Employees

500 - 1000

Certifications

Gdańsk

Poland - 80-426

Founded

1954

Employees

200 - 500

Certifications

Tesanj

Bosnia & Herzegovina - 74260

Innovative technology Made in Germany Since it was founded by Fritz Faudi in 1938, FAUDI has stood for innovative filtration and separation technology. Today, with its two product areas Coolant (coolant treatment) and Process (treatment of process fluids and gases), FAUDI GmbH guarantees high-quality plant engineering Made in Germany, which of course takes into account all important international approvals and certificates. FAUDI is committed to Germany as a location: At our headquarters in Stadtallendorf, central Hesse, we focus on project planning, engineering, construction, manufacturing, service, sales and marketing in order to provide our customers with the best solutions from a single source. Our representatives in all major regions of the world make it possible to serve our local customers promptly. We offer you genuine filtration solutions for a wide range of tasks. Our products and services help you comply with regulatory requirements and improve performance while reducing operating costs. Because when we talk about quality at FAUDI, it goes beyond the categories of durability and freedom from faults: “Total cost of ownership” (TCO) is an important benchmark for our engineers when it comes to project planning work. FAUDI uses its patented filter systems without filter aids. This results in less waste, which is not only economical but also serves to protect the environment and our planet. The plant processes are fully automated and therefore support and simplify work processes. The exclusive use of high-quality components in product design are key reasons why FAUDI systems are so durable and safe. We're here to help you achieve your goals.

Founded

1938

Employees

50 - 100

Certifications

Stadtallendorf

Germany - 35260

We not only produce sporting rifles for Olympic champions (www.bleiker.ch) but also your precision mechanical parts. Our capabilities: Production of high-tech sporting rifles Milling/5-axis wire erosion sinker erosion Highly dynamic simultaneous 5-axis machining Electrode manufacturing Innovative product and process development

Founded

Employees

10 - 20

Certifications

Bütschwil

Switzerland - 9606

We see ourselves as a reliable partner for high-quality complete mold manufacturing solutions. As HemaTec, we are proud to be able to provide individual support to our customers throughout the entire product life cycle. Our portfolio ranges from article or module design, through tool design and mechanical production, to initial sampling and the initial sample test report. We would be happy to take on series production and all associated tasks for you. Our specialty is comprehensive project management, from development to assembly of a finished assembly and its testing - every detail is carefully checked to ensure that our customer receives the best possible result. Our production facility is equipped with cutting-edge equipment and technologies to ensure the highest efficiency and quality.

Founded

2023

Employees

5 - 10

Certifications

Herford

Germany - 32052

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

VULIC - ECM is an international company with a focus on electrochemical deburring (ECM) for high-quality ECM deburring systems as well as their devices and spare parts. VULIC - ECM is constantly striving to find new ways for technical innovations and applications. One of the main reasons for comprehensive performance is the professional competence and continuous commitment of every employee. Efficient technology, perfect service: VULIC - ECM has consistently implemented the requirements of its customers and practical experience for the development and optimization of deburring systems. The company is qualified in accordance with the international standard DIN ISO 9001. In addition to general market requirements, our management system also meets other requirements in the areas of environmental protection, occupational safety, and data protection.

Founded

2007

Employees

10 - 20

Certifications

Ottobeuren

Germany - 87724

Our company is comprised of specialists with backgrounds in automotive and aerospace manufacturing. We deeply understand what quality and precision truly mean. We’re prepared to develop unconventional solutions and approach every project with uncompromising quality standards.

Founded

2022

Employees

5 - 10

Certifications

Kharkiv

Ukraine - 61000

ISOPROFIL provides unique solutions with metal. Made of steel and stainless steel, we process materials made of aluminum, brass, copper, steel and plastic into finished parts or assemblies including surface treatment. We always guarantee 100% functionality — all components are coordinated and together form a perfect system. With over 40 years of experience and a wide range of services, ISOPROFIL sees itself as a reliable partner for individual profile solutions in various industrial sectors such as mechanical engineering, aviation, architecture, medical technology and more.

Founded

1983

Employees

20 - 50

Certifications

Wuppertal

Germany - 42327

WIRO GmbH — metal construction with substance. Technology with measure. As a technical wholesaler with its own production facilities, WIRO GmbH stands for practical solutions, maximum precision and tailor-made technology. Our focus is on metal construction and mechanical processing, supplemented by cutting-edge manufacturing options in filter technology, 3D printing and technical textile processing. 🏗️ Metal construction & machining — our core competence In our in-house metal processing department, we combine classic craftsmanship with the latest technology. Whether it's a special part, a single item, a small series or series production — we manufacture precisely according to drawings, samples or a jointly developed concept. An overview of our services: Machining: CNC turning, milling, drilling — highly precise and economical Sheet metal processing: laser cutting, edging, punching Welding technology: MIG/MAG/TIG welding Design & development: CAD-based planning, feasibility assessment, implementation Assembly & assembly: everything from a single source Typical applications: Machine parts, mounts, supports, covers Special frames, sheet metal housings, devices Repair or spare parts for systems and machines Our customers particularly appreciate: ➡️ Flexibility with special solutions ➡️ short response times ➡️ manufacturing-related advice from real professionals 🔩 More than just metal — our extended range of services: 🌀 Filter technology — standardized or individually manufactured filter mats, pocket filters, filter bags Special formats made to measure for OEM or retrofit Short-term delivery capacity through in-house production 🖨️ 3D printing — shape ideas in record time prototyping, functional components, small series Support with design & choice of materials Ideal for individual adjustments or missing spare parts 🧵 Textile processing — tailor-made protection & function robot protection, machine covers, lift covers Individual mounting bags and special solutions Robust materials, precise workmanship, long-lasting use 💡 WIRO GmbH — your project. Our solution. With experience, manufacturing depth and technical expertise, we meet your requirements — from the idea to the finished product. ✔ Made to measure from quantity 1 ✔ Metal processing with passion & precision ✔ Personal advice, direct contacts ✔ Everything from a single source — efficient, solution-oriented, on schedule 📞 Talk to us about your requirements! WIRO GmbH — where technology becomes a solution. We are looking forward to your request.

Founded

1992

Employees

10 - 20

Certifications

Twistringen

Germany - 27239

We specialize in high-precision CNC machining for the medical and aviation industries. With years of expertise and 5-axis capabilities, we produce complex parts from plastics, composites, aluminum, alloys, and stainless steel. Leveraging advanced CAM software and automation, we ensure cost-effective, accurate, and reliable production. Certified to ISO 9001:2015, we guarantee top quality through 100% in-house inspection and efficient workflow management.

Founded

1992

Employees

10 - 20

Certifications

Tallinn

Estonia - 11415