Discover specialized suppliers for milled parts on Techpilot. Our platform connects buyers with manufacturers delivering precision components made through milling processes. Use the e-sourcing process to optimize your sourcing.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

CNC PRODUCTION Turning, milling (5-side machining), grinding with state-of-the-art machining equipment according to current production techniques. We offer machining and high-precision finishing using different production techniques. Individual one-off production as well as serial production according to customer requirements. METAL AND TOOL MAKING Production of tools for hot forging presses (horizontal), complete new production and regeneration offer ready-to-install solutions. Individual areas of the value chain can be processed here.

Founded

1847

Employees

10 - 20

Certifications

Ortenberg

Germany - 77799

CNC milling contract manufacturing We can manufacture plastic, aluminum, brass, copper, steel, stainless steel and tool steel components using a 3-axis CNC milling machine. Key data Minimum component size: 7 x 7 x 7 mm Maximum component size: 450 x 160 x 150 mm Processing in the uncured state (steels) Prototypes individual parts small series Machining strategies Milling Deburring / chamfering Drill Tapping Reduce Rub Thread milling engraving 3D processing Materials plastic Brass aluminum copper steel stainless steel Tool steel

Founded

Employees

Certifications

Spalt

Germany - 91174

ASAB GmbH Augsburger steel, engineering and tank In 1994, the company ASAB GmbH was founded as a "management buy out" of Pfister Waagen Augsburg. At 2500 sq foot was caught with initial staff of 11 in the apparatus and container. The successful and constant specialization of custom steel and stainless steel the company has ASAB GmbH can grow to 30 employees in the meantime. In 2005 was combined with the partner company Spegel GmbH (www.spegel.de) to a new building with 3600 m² and 400 m² production office in the Ostrachstraße. Today the ASAB GmbH also handles the business operations of Spegel GmbH. The Spegel GmbH acts as a holding company. An ultra-modern machinery along with qualified and motivated employees guarantee the highest precision and quality of our products in very short delivery time. Our motto is: The more difficult, the better! Schweißtechnken and welding processes: Welding and cutting (up to 300 mm in steel) in Autogentechnik Welding with stick electrodes Arc welding in MIG / MAG and TIG process Automatic welding by means of a modern 800 amp UP-conditioning Spot welding machines The following materials we process among others: general structural steels such as S235 (37-2) and S 355 (St 52-3) Stainless steels from 1.4031 to 1.4579, Hastelloy Aluminum alloys Cu-Ni alloys, Black / white joints Production We

Founded

1946/1995

Employees

20 - 50

Certifications

Augsburg

Germany - 86165

HISTORY The craft business, founded in 1961 by Mr. Johannes Richter Senior, has been successfully continued and expanded by Mr. Peter Richter to this day. Our company has been located in the GADA / Bergkirchen industrial estate since 2009. In 2013 we were able to name Mr. Stefan Frank alongside Mr. Peter Richter as managing director. OPPORTUNITIES With our modern machinery and corresponding know-how, we can deal individually with all tasks. TRAINING OPERATION As a conscientious training company, we are committed to providing information events and offers on site, future-oriented and with social responsibility. EMPLOYEE All of our employees were trained and taken on within our company. In addition, further education and training are carried out.

Founded

1961

Employees

5 - 10

Certifications

Bergkirchen/GADA

Germany - 85232

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Leutz Lötsysteme GmbH is an innovative, dynamic and flexible family company. We offer the development, construction and manufacture of parts and devices.

Founded

1986

Employees

5 - 10

Certifications

Albershausen

Germany - 73095

The Modellbau H. Brüggemann Gmbh For decades, predominantly classic wood models were manufactured for the foundry industry. In the course of In the course of time, the company structure and range of products changed several times. Due to the continuous development of the company in 1977, a new, larger premises in Hemer, the present headquarters of the company, can be obtained. This allowed the machine park to be expanded and additional production areas to be gained. Today, the company employs 15 highly motivated and specially trained employees on an area of about 1000 square meters. The technical know-how as well as responsibility and quality awareness are kept at the highest level by permanent training and further education. It is our ambition and obligation to satisfy our customers every day and to master the daily new tasks in a personal dialogue with you.

Founded

1906

Employees

10 - 20

Certifications

Hemer

Germany - 58675

Founded

1979

Employees

50 - 100

Certifications

Bursa

Turkey - 16235

solder masks soldering form Lakierträger Contract manufacturer milling 5 axis milling Milling plates jig Assembly

Founded

2010

Employees

10 - 20

Certifications

Soest

Germany - 59494

Series and component assembly Cable assembly Measurement technology environmental, Vibration and climatic test Mechanical machining

Founded

1973

Employees

Certifications

Markdorf

Germany - 88677

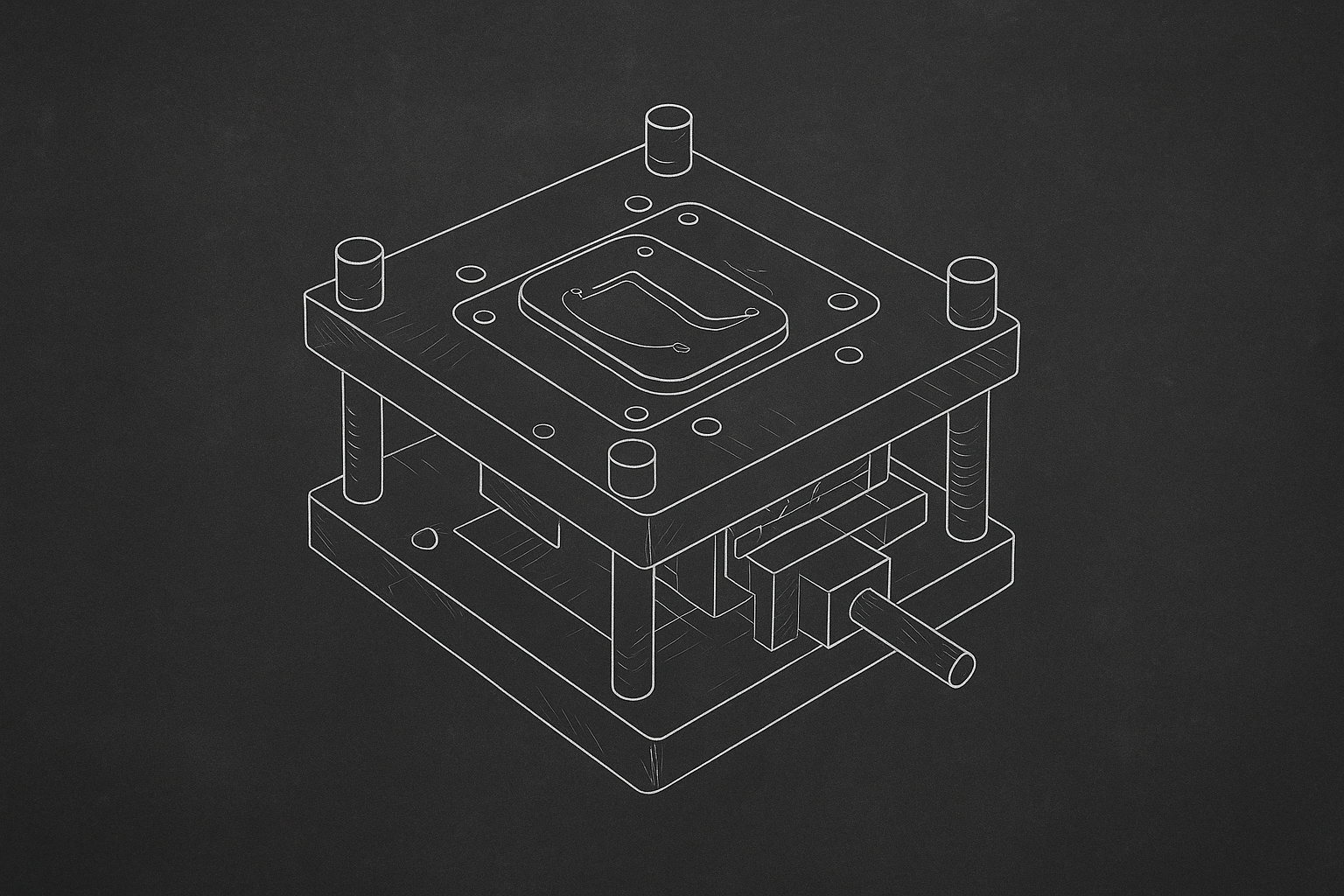

Impuls 97 Ltd. is a European manufacturer specializing in high-quality plastic components and custom mold-making. For over 20 years, we have been a trusted partner to companies across diverse industries, delivering precision, reliability, and innovation. What sets us apart is our end-to-end expertise: we not only produce plastic components, but also design and manufacture the molds in-house. This integrated approach ensures shorter lead times, optimized costs, and consistent quality. Our in-house team of experienced engineers supports clients from concept to production, offering solutions tailored to specific technical and business needs. Thanks to modern equipment and continuous improvement of our processes, we are able to meet demanding requirements for both small series and large-scale production. Core competencies: Plastic injection molding Design and manufacturing of molds Engineering support and co-development Custom solutions for industrial applications At Impuls 97, we take pride in combining family-business values with European industry standards — building long-term partnerships based on trust, flexibility, and technical excellence.

Founded

1990

Employees

20 - 50

Certifications

Voivodinovo

Bulgaria - 4002

TCM Germany is a subsidiary of TCM International GmbH. The headquarters of TCM International GmbH are in Stainz (Austria). In addition to numerous holdings, it has branches in Germany, Luxembourg, Poland, the Czech Republic, Hungary, France and China. As an innovative technology partner in machining production, the TCM Group offers a diverse portfolio of services. This ranges from the tool trade and output systems of the “TOOLBASE” brand to the complete, productivity-oriented TOOL MANAGEMENT service. In order to be able to support TCM customers even better and to meet modern requirements of "Smart Production", the company WinTool with the tool management software of the same name is one of the cornerstones of the TCM Group. The TCM company portfolio is rounded off by its own training program in which technical expertise on machining processes and their environment is imparted in a modular and manufacturer-independent manner.

Founded

1996

Employees

500 - 1000

Certifications

Gladbeck

Germany - 45966

Our company was founded in 1985 as a mobile portal machine tool manufacturer. To overcome the crisis of the 90s, collaboration began with the company ORTHOFIX S.r.l., a world leader in external orthopedic products, in particular, the engineering of prototypes and pre-series was studied. As the stagnation in machine tools persisted, in 1997, we switched to the production of orthopedic modular systems on behalf of ORTHOFIX S.r.l., including the construction of bone cortical screws. We subsequently added other customers, always consistent in their qualitative needs, such as OMV MACHINERY S.r.l., a leader in the production of machinery for the production of food containers, the P. BERETTA WEAPON FACTORY in Gardone Valtrompia, BALZARIN S.r.l. which deals with the design, construction and processing of sheet metal molds. We specialize in the processing of steels according to UNI EN 10088-1 AISI/ASTM, aluminum alloys, plastic materials (PSU-Polysulfone, Pom C, Nylon, etc.) and thermoforming materials. We have chosen to have few qualified customers so that we can guarantee, not only quality, but also delivery. This is why we manage our warehouse of parts agreed with the customer. In 2023, the company had more than one million euros in turnover and can count on 10 qualified employees. Thanks to the support of our qualified suppliers, we are able to provide surface treatments such as hard anodic oxidation after tumbling, vacuum hardening, sandblasting, stainless steel polishing, electropolishing and laser marking. Our production is continuously monitored according to quality specifications, designed to exceed the strictest standards, and everything is archived for traceability of both production and raw material.

Founded

1985

Employees

5 - 10

Certifications

Pescantina

Italy - 37026

As a specialist for special and precision turned parts in the field of turning, milling and grinding parts, we serve clients in the areas of aerospace, Automotive, electrical and drive systems operate. Other customers of Pneumatics, hydraulics and connection, high frequency and Medical part of our long-standing customer base. The machining of aluminum, plastics, carbon and vending machines and hardened steels represents for us no problems In particular, we can nickel - chromium - alloys and stainless steels and heat resisting steels in smaller and medium quantities manufacture for you. Also materials from the aerospace industry can be edited with our machinery. Of course, we are also certified according to DIN EN ISO 9001:2000. In addition corresponds to our quality management system the requirements of the Federal Association of the German air and space industry and has been audited by QSF-B (EN 9100).

Founded

1937

Employees

50 - 100

Certifications

Waldkirch

Germany - 79183

Founded

1985

Employees

< 5

Certifications

Zimmern ob Rottweil

Germany - 78658

Manufacturer of attachment tools for Baumschinen

Founded

1997

Employees

10 - 20

Certifications

Goldenstedt

Germany - 49424

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

DVM Technology provides experts in metalworking, CNC machining, plasma cutting, welding, and custom design services to provide high-quality solutions for projects of any size.

Founded

Employees

< 5

Certifications

Pirot

Serbia - 18307

Our Company Our company is successful in the supplier market for CNC milling and turning parts active since 1992. Initially founded as a one-man company, the employee and turnover figures and the available machines and premises grew continuously. Our clients include mainly foundries, companies in the automobile industry of agricultural machinery and general machinery as well as a particular degree in the field of hydraulic engineering. Currently we are producing a two-shift system on a highly modern machinery. Our current equipment list can be found in the area of services. Our range of services We have specialized in the CNC milling of prismatic parts such as gearbox, engine parts, hydraulic or other machine components. Loading and unloading of even very large vehicles are under cover. Basically, workpieces can be processed with the following parameters: Prismatic parts: - Max. Edge length 1400x1250x1250 mm - Max. Weight 1500 kg - Bore tolerance IT6 - Positioning accuracy 0.006 mm We are happy to face new challenges and look forward to your inquiry.

Founded

1992

Employees

5 - 10

Certifications

Chemnitz

Germany - 09117

Adestra metalworking, flexible modern enterprise, the sheet metal and tube machining, and mechanical machining can offer turning and milling. We design, produce and assemble according to customer requirements: housing, terminals, machines, machine covers, custom solutions, components and assemblies.

Founded

1994

Employees

50 - 100

Certifications

Pilsen

Czech Republic - 301 00

Váll-Ker Ltd. was established in 1992 with the goal of meeting the industrial and machining needs of local businesses. Our dynamic company is committed to providing high-quality services that contribute to the business success of our partners.

Founded

1992

Employees

200 - 500

Certifications

Mako

Hungary - 6900

Short profile A + G Präzisionsformenbau As specialists in the precision mold, we offer our customers comprehensive service package. Our service includes the design, development and of course, the manufacture of tools for all areas of plastics engineering. We are capable of producing molds up to a weight of 3500 kilograms. Currently about 30 employees work in our headquarters in Bad Windsheim (BY). The large number of professionals enables us to offer individual solutions in record time. Translation by Google Translate

Founded

Employees

20 - 50

Certifications

Bad Windsheim

Germany - 91438