Find specialized suppliers for turning on Techpilot. Our platform offers access to suppliers who use advanced turning technologies to manufacture precise and customized parts. Benefit from comprehensive market transparency and optimize your supplier selection.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

Your fastening solutions designed, manufactured and optimized, worldwide

Founded

1934

Employees

50 - 100

Certifications

Avrillé

France - 49240

Precision is our passion Your specialist for CNC manufacturing technology and individual precision parts.

Founded

2009

Employees

5 - 10

Certifications

Ried

Germany - 86510

Since the company was founded in 2004, we have set ourselves the task of inspiring you with our sophisticated services in machining technology. Benefit from our professional and personal expertise, our reliability and our quality and solution-oriented work. Thanks to our modern and flexible machines, we can serve customers from a wide range of industries and also offer them complete solutions. Our customers include companies from the fields of tool and mechanical engineering, aerospace technology, medical technology and the automotive industry.

Founded

2004

Employees

10 - 20

Certifications

Ötisheim

Germany - 75443

R&G Plast – We turn ideas into precision. We design and manufacture high-quality injection molds and plastic components for automotive, industrial, and home appliances sectors. From concept to serial production, we deliver complete solutions with ISO 9001 & IATF 16949 standards. Modern machinery, flexibility, and passion for innovation make us a reliable partner for demanding projects.

Founded

2012

Employees

200 - 500

Certifications

Mielec

Poland - 3900

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Focus areas: • Processing of fine-grained structural steels up to S960QL • Welded structures up to 13 m in length • Large components up to 5 t component net weight • Mechanical processing up to 6,300 x 1500 x 1800 mm • Engineering services • Fixture construction with construction as a business area Certifications: • ISO 9001:2015 vehicle-connecting components) • KBA certified in accordance with German and international road traffic law • Welding approval for fine-grained structural steels up to S960QL including all process tests from S355 to S960 hand and robot • EN 15085 2 CL 1 (rail vehicles) • Manufacturer qualification in accordance with DIN 2303 Q2 BK1 • Welding certificate DIN 18800 7 class E • Welding certificate for welding steel structures up to EXC3 in accordance with EN 1090 2 • • Approval in accordance with ÖNORM EN ISO 3834 2

Founded

2000

Employees

100 - 200

Certifications

Thalgau

Austria - 5303

Development at the highest level No compromises in quality and performance From transmissions, axles, vehicle components, systems and kits to entire vehicles in the area of very small and small series, Oberaigner can draw on decades of experience and expertise. Our expertise lies particularly in the entire vehicle powertrain, including axles and axle suspension, in particular in the area of all-wheel drive technology and special transmissions for special applications. Oberaigner is a long-standing system supplier to the automotive industry, certified in accordance with IATF 16949. Through continuous development of our management and QA system, we can ensure the provision of services using the latest facilities and methods, both for our own developments and for our customers. The components, aggregates, systems and vehicles developed by Oberaigner are subjected to extensive testing and testing in accordance with the latest standards in the automotive industry and in accordance with the specifications of our customers. When carrying out various tests and evaluating the results, we work closely with both clients and competent service providers, partners and scientific institutions in order to be able to offer our customers the best and safest product.

Founded

2002

Employees

100 - 200

Certifications

Nebelberg

Austria - 4155

Since 1969, we have been your reliable partner for CNC machining services. With a team of 20 employees, we offer high-precision turning and milling work for various industries. Our focus is on quality and customer satisfaction. Contact us to find out how we can meet your manufacturing needs.

Founded

1969

Employees

10 - 20

Certifications

Emmendorf

Germany - 29575

We are a company that is dynamically developing in the field of CAD design and CNC services. With many years of experience in the industry, we provide comprehensive services tailored to the individual needs of our clients. Our modern machine park offers a wide range of applications, enabling us to carry out complex projects. We take pride in our reputation and the trust our clients place in us.

Founded

Employees

5 - 10

Certifications

Rzeszow

Poland - 35203

For 60 years, we have specialized in: - Precision optical products - Technical glass products - Custom glass processing Planoptik e.g. windows, mirrors and prisms ✅ highest surface accuracy single lenses single lenses lens geometries e.g. concave, convex, spherical, aspherical ✅ tailor-made with maximum precision special components special components for special applications e.g. small series and prototypes ✅ individual production Technical glasses Technical glasses Processing and finishing e.g. glass rods, glass rings, light guides ✅ highest dimensional accuracy and surface quality glass processing glass processing e.g. blanks, semi-finished products, radii ✅ individual and perfect fit filters filters e.g. individual filters, filter groups ✅ Application-specific Tailored

Founded

1960

Employees

10 - 20

Certifications

Königs Wusterhausen

Germany - 15712

Founded

1954

Employees

200 - 500

Certifications

Tesanj

Bosnia & Herzegovina - 74260

Dear ladies and gentlemen! As H. Conle Wespe GmbH, we would like to introduce ourselves to you as a reliable partner in the precision manufacturing of machine components and weapon parts as well as rifle and pistol barrels of various calibers. Since our founding in 2019, we have stood for the highest standards of quality, precision and reliability. Our many years of experience in special machine construction enable us to efficiently implement complex manufacturing tasks using the latest technology. Our range of services includes: • Deep hole drilling technology • CNC turning and milling • Wire EDM • Honing and grinding • Burnishing, hardening, bluing and anodizing • 3D printing • laser engraving • Official shooting • Weapons work (including pulling, changing caliber, cutting cartridge storage and muzzle threads and much more) • R93 and Mauser barrels, special barrel shapes Many other works — upon request. In-depth insight and information can be obtained at any time from our Find the homepage www.wespe-gmbh.at. We would be delighted to support you with future projects and develop optimal solutions together.

Founded

2019

Employees

5 - 10

Certifications

Ferlach

Austria - 9170

Walle GmbH - Your specialist for turning parts, milling parts, CNC turned parts, CNC Milling, Conventional production, medical We offer the production of turned parts and machined parts according to your wishes. Our machines are on the cutting edge technology of CNC and ensure the highest standard of precision.

Founded

1974

Employees

20 - 50

Certifications

Blieskastel-Biesingen

Germany - 66440

MecProtec is a manufacturing service provider with a focus on CNC machining, special machine construction and project management. We produce precise turned and milled parts for mechanical and plant engineering as well as for special industrial applications. With modern CNC technology, clear processes and short decision-making processes, we produce individual parts, small and medium-sized series reliably and on time. Our work is based on technical understanding, reproducible quality and clean implementation. We think in a solution-oriented way, speak the language of designers and buyers and assume responsibility — from component to result.

Founded

Employees

< 5

Certifications

Gummersbach

Germany - 51643

Laserexpress GmbH is a specialized service provider in the area of contract manufacturing for metal and plastic components. As a reliable industrial partner, we manufacture tailor-made products exactly according to customer specifications — from individual parts to completely assembled components, including all standard surface treatments. Our range of services includes sheet metal processing, machining, welding technology and assembly. Our portfolio is supplemented by powder coating, which is carried out within our group of companies. In this way, we offer all services from a single source and guarantee the highest quality, precision and punctuality. We can also arrange delivery flexibly with our own fleet of vehicles. With a clear focus on customer orientation and technical expertise, Laserexpress GmbH is your reliable partner for sophisticated manufacturing solutions.

Founded

1996

Employees

100 - 200

Certifications

Cuxhaven

Germany - 27472

With more than 35 years of experience, PENCOM provides global manufacturing services that combine state-of-the-art technology, engineering expertise, and efficient supply chain management. Our worldwide network of manufacturing facilities and distribution centers ensures on-time delivery, optimized production costs, and consistent high-quality parts. Core Services & Specialties Precision Machining & Metal Forming CNC Machining: Precision parts with complex geometries, tight tolerances, and versatile materials like aluminum, steel, brass, and plastics. From prototyping to production. Metal Stamping: High-speed progressive stamping, custom tooling, and consistent quality assurance for intricate metal components. Automatic Screw Machining: High-speed production for precision-turned components, optimized for cost-efficiency and tight tolerances. Molding & Casting Solutions Plastic Injection Molding: Durable parts using thermoplastics and engineering-grade resins. Includes insert molding for hybrid components and flexible production runs. Die Casting: Lightweight, corrosion-resistant aluminum, zinc, and magnesium parts with close tolerances and automated, high-volume production. Insert Molding: Integrating metal and plastic for hybrid components, streamlining assembly. Fastener & Component Manufacturing Cold Heading: Efficiently produce strong, high-integrity fasteners and specialty hardware with minimal material waste. Assembly Services: Combine molding, machining, and fastener integration to deliver ready-to-use products with reduced lead times. Finishing & Quality Assurance Secondary Services: Surface treatments like plating, anodizing, and painting to enhance aesthetics and durability. Post-Processing: Tapping, deburring, polishing, and more to refine components. Quality Control: Advanced inspections ensure every part meets specifications. Industries We Serve PENCOM’s manufacturing solutions cater to a diverse range of industries, each with unique requirements for precision, reliability, and cost-effectiveness: Automotive: Engine components, electronics housings, interior parts. Aerospace & Defense: Lightweight, high-strength parts built to stringent quality standards. Medical & Healthcare: Biocompatible plastics and metals for durable, precise components. Consumer Electronics: Compact, high-volume parts with fine detail. Industrial & Automation: Robust mechanical parts for assemblies and factory machinery. Energy & Utilities: Corrosion-resistant materials for harsh operating environments. PENCOM’s Quality & Engineering Support ISO-Certified Systems: Our facilities follow recognized quality standards to ensure consistency in every batch. Advanced Equipment & Technology: CNC machines, automated presses, and high-precision tooling deliver reliable results. Design Optimization: Work with our engineers to reduce material usage, simplify part design, and improve product longevity. Prototyping & Testing: Validate part performance and refine designs before committing to full-scale production. Dedicated Project Management: A single point of contact for streamlined communication and timely updates.

Founded

Employees

500 - 1000

Certifications

Gdańsk

Poland - 80-426

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

ISOPROFIL provides unique solutions with metal. Made of steel and stainless steel, we process materials made of aluminum, brass, copper, steel and plastic into finished parts or assemblies including surface treatment. We always guarantee 100% functionality — all components are coordinated and together form a perfect system. With over 40 years of experience and a wide range of services, ISOPROFIL sees itself as a reliable partner for individual profile solutions in various industrial sectors such as mechanical engineering, aviation, architecture, medical technology and more.

Founded

1983

Employees

20 - 50

Certifications

Wuppertal

Germany - 42327

We have been a family business since 1987, starting with the repair of bicycles. Today, we are a modern contract manufacturer in the area of turning and milling. We use the latest technology for this. From simple 3-axis milling to 5-axis simultaneous milling, as well as lathes with Y-axis and counter spindle. We have also equipped 2 machines with robotics to make optimal use of our capacities.

Founded

1987

Employees

5 - 10

Certifications

Brandenburg - Werder (Havel)

Germany - 14542

We are engaged in the production of individual and serial parts in the field of machining

Founded

1956

Employees

10 - 20

Certifications

0 Salzburg

Austria - 5020

Traditional family business with focus on CNC manufacturing and a modern product portfolio. Our motto: Our heart beats for metal. Since 1947.

Founded

1947

Employees

5 - 10

Certifications

Föritztal

Germany - 96524

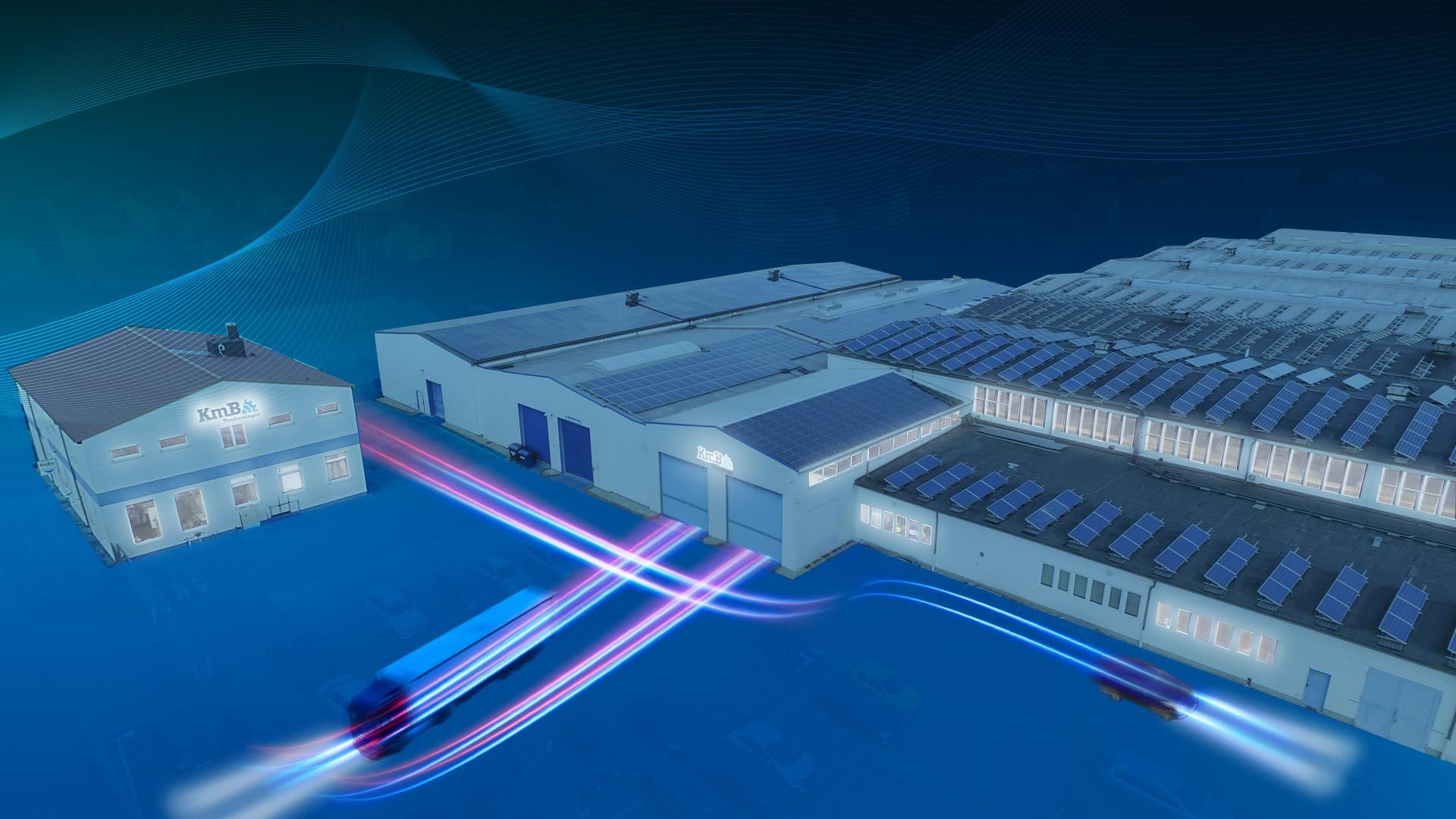

As a “turner”, KmB was founded in 1995 and is today one of the most renowned automotive suppliers in Saxony-Anhalt. Our high-precision turned and milled parts are used in steering systems, transmissions and chassis from various automotive manufacturers. Through a variety of cutting and chipless processing technologies, we create sophisticated automotive components in small and large batches — semi-finished or ready for installation, digitally connected across the entire supply and value chain.

Founded

1995

Employees

100 - 200

Certifications

Zerbst

Germany - 39261