Discover contract manufacturers for milling services on Techpilot. Our platform connects buyers with suppliers offering precise CNC milling for various materials. Use the e-sourcing process to compare offers.

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

Supplier of precision machined parts (individual parts and small series) according to customer drawings for medical technology, precision engineering and optical industry, laboratory, and laser industry Processed materials: aluminum, steel V2A, plastics, non-ferrous metals Tolerances and surfaces: Flatness to 0.003 mm; Ra> 0.04; Machining tolerances + / -0.01 Mm; Complete processing including surface treatment such as zBElox (also decorative with no visible machining marks), nickel plating, gold plating ... Laser engraving in copper and other materials CNC 3-coordinate measuring technique Data transfer

Founded

1991

Employees

20 - 50

Certifications

Laasdorf

Germany - 07646

Our company for more than 40 years is of high quality tools and injection-molded parts, because your claims deserve quality. From concept, through mold to mass production. ABOUT US 25 employees which 4 trainees Tooling - Plastics Processing - Subcontracting about 1500m² production area generous storage facilities CAD-CAM systems Unigraphics NX, ME10 OneSpaceDesigner and PEPS CNC milling machines from DMG and Mikron Wire EDM machines from AGIE EDMs of AGIE and Zimmer + Kreim CNC lathe of nuclear Grinders from Jung and Elf Injection molding machines from Arburg High quality and durable tools are the result of years of experience that have come to appreciate our customers in the automotive, electrical and household goods industries as well as the environmental, medical and packaging technology. Both injection molds (multicomponent) as well as in press tools and MIM (Metal Injection Moulding), we are your partner! Our highly trained and trained staff set for you to to always modern equipment what you expect from a modern tool! In our plastic processing, we can test the tools for you extensively, and if you want, also happy to produce zero, small and large series!

Founded

1970

Employees

20 - 50

Certifications

Wipperfürth

Germany - 51688

Aluminum is our competence. Metal and contract manufacturing from a single source! The GLEICH Group is a traditional family business from Kaltenkirchen, near Hamburg. Founded in 1980 by Günter and Christel Gleich, the group of companies is now run by Roland Gleich in the second generation. Since the mid-1990s, the core business has been the development, production and worldwide distribution of G.AL® aluminum panels. The brand name G.AL® stands for extremely low-warpage, dimensionally stable and homogeneous aluminum precision and mold boards with consistently good quality. A special manufacturing process allows us to clearly distinguish it from conventional aluminum slabs. Our customers benefit from the resulting unique material properties by significantly reducing production times and component costs. As a unique service package, you will receive from us both the raw material from our own production and the finished drawing part. Travel distances of up to 3,000 x 4,000 are possible here.

Founded

1980

Employees

100 - 200

Certifications

Kaltenkirchen

Germany - 24568

Founded

Employees

5 - 10

Certifications

Bornova

Turkey - 35060

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our company was founded in 1966 and since then we have always worked in the field of mechanical machinings and assemblings for third parties. We decided not to start a production programm on our own but to concentrate our efforts on our qualities of flexible and reliable supplier who addresses to his customers with the aim to satisfy their needs in a common way of technological growth. We constantly work in close cooperation with our customers for the development of the production process of mechanical parts with the features of considerable complexity and functional importance: our references are our best visiting cards and the first reason of pride for our team. The PASSION for mechanic, the COMPETENCE in our field, the TECHNOLOGY of the equipments, the ABILITY and the MOTIVATION of our staff, are the reasons of the excellence of the results we have obtained up today .

Founded

Employees

20 - 50

Certifications

Rescaldina

Italy - 20027

KML Precision Machining GmbH offers a wide range of services in the field of manufacturing technology. Since 2013 we have acted as a manufacturing partner for technologically sophisticated manufacturing parts all materials. In addition to mechanical processing, surfaces, heat treatment and partial assemblies can also be offered. Production of precision individual and serial parts Production of assemblies (including assembly and measurement protocol) Complex 3D and 5-axis milling operations in all materials freeform surfacing eccentric parts cam making All common data formats (e.g. step, iges, Pro/E, dif, Catia V5, etc.) can be processed to transmit the article data.

Founded

2013

Employees

20 - 50

Certifications

Wien

Austria - A-1100

Micromeccanica Srl is a leader company in the realization of Tools, Machinery, Industrial Automatic Equipment, serial parts. To ensure a full support to our clients, we also guarantee different typologies of Services such as Co-Design / CO-Engineering, Prototyping, metrological surveys to get both an inner control of the product and an ad-hoc metrological survey for client, Maintenance, after-sale Service and much more. Our workshop is characterized by different departments with machines tools connected to the 3D CAM Design Department through a direct post-processor. We are fully equipped with 3 and 5 axles multitasking milling, deep drilling, wire and die sinking EPDM, cylindrical and tangential Grinding, Turning, TIG and laser welding, metrological control with dimensional Report at the end of the cycle, tool trial and everything can be needed. All this allow us to reach a high-quality level of products and make possible the finishing precision. We have an Export Sales Department interacting with our worldwide customers in different languages. We are fully specialized in productions addressed to the Automotive field and diversifying our know-how, we easily adapt our skills and knowledge to other industrial fields such as Appliance, Food, Aeronautical and Electricity Industries. Besides having a Quality Management System in accordance with UNI EN ISO 9001:2008 and UNI EN ISO 14001:2004 Rules, the Certification in accordance with the IATF 16949:2016 technical specification is under implementation.

Founded

1980

Employees

50 - 100

Certifications

Salerno

Italy - 84135

Finish: ENERGY EFFICIENT, dimensionally stable, FRIENDLY MATERIAL Wage treatment: -Plasmanitrieren -Plasmanitrocarburieren And Oxidation -Abhol- U. Deliveries by arrangement -Werkstoffberatung Construction of plasma nitriding on customer Research and Development Delivery time: from 24h - We give everything, so you do not lose any time! The company: The company Plasmanitriertechnik was established in September 1996 by Prof. Dr.-Ing. Sabine Böhm founded. The goal was and is to offer plasma heat treatment as a contract manufacturer, as well as promote research and development in the fields of plasma and materials technologies and associated systems engineering. Since its establishment, our company has become a reliable partner for the machinery and vehicle and tool making. The services and core competencies of wage treatment include plasma nitriding, plasma nitrocarburizing and oxidation.Capacity for the processes offered are steadily built up to meet the growing demand for these Oberflächenh��rtungsmöglichkeiten can. In the meantime more than 15 years of business, the company can look back on a steady development. Quickly rose to the top customer number and order volumes, so now have 8 plants for plasma nitriding and nitrocarburizing in operation. With the move from the old location in the center of Chemnitz technology to its current location in the Robert-Blum-Str. in Chemnitz in 2005, this possibility was created for this extension. Since 2005, the plants are built themselves and, since 2010, the construction is performed in-house. In addition to building their own systems also several engineering projects for various customers were realized. In addition to the wage treatment plant and existing technologies in research and development projects developed, established innovative procedures, as well as designed and constructed new facilities.Research topics include the plasma polishing, atmospheric plasma treatment, and the use of existing technology in new application areas. It is working closely with a variety of partners from industry, universities and research institutions. The number of employees has been expanded from an initial 2 now on 12 full and part-time employees. Many trainees have completed their required internships. Students of universities and technical colleges, and technical schools enrolled diploma, bachelor and technicians working on topics of plasma nitriding and related topics. For the future is important for us not to stand still, but develop ourselves. With research and development projects, we intend to further develop the technology. New facilities should be designed and constructed. In best way we want to be there for our customers and the orders done quickly and in very good quality.

Founded

1996

Employees

10 - 20

Certifications

Chemnitz

Germany - 09116

Frez Projekt provides services in the scope of comprehensive metal and plastic processing with the use of CNC machines. Our knowledge and many years of experience is what enables us to successfully execute even the most difficult tasks. We cooperate with companies operating in many lines of business, including automotive, medical, food or construction, which enables constant development and increasingly better adjustment to the needs and requirements of clients, including the most demanding ones. We manufacture singular small items, as well as small and medium product series. Our main assets are the following: • high quality of product and attention to details • comprehensive services, including designing • short delivery dates • our own transport

Founded

2013

Employees

5 - 10

Certifications

Krzymow

Poland - 62513

Keppler- Precision Engineering is a successful family business for demanding and geometrically complex components made of thermoplastic materials, high-temperature Plastics and metal injection molded parts in MIM technology (Metal Injection Molding). Innovation, precision and absolute customer satisfaction are for more than 48 years to our corporate philosophy. Our service program includes mold making, construction of customized measuring and test equipment, metal injection molding using MIM technology and the production of precision plastic parts, especially of technically sophisticated and geometrically complex small parts weighing 0.002 to 25 gr. Customers in the medical, electronics, optical industry, measuring and control technology and various fields of precision engineering industries appreciate our precision, quality and punctuality.

Founded

1967

Employees

10 - 20

Certifications

Engelsbrand

Germany - 75331

The azw is a reliable partner for the settlement of commercial work. A dedicated team of production staff and learners produced for you to advanced machinery and equipment. In the highest quality and on time and at competitive prices, we carry out your order.

Founded

2002

Employees

50 - 100

Certifications

Winterthur

Switzerland - 8401

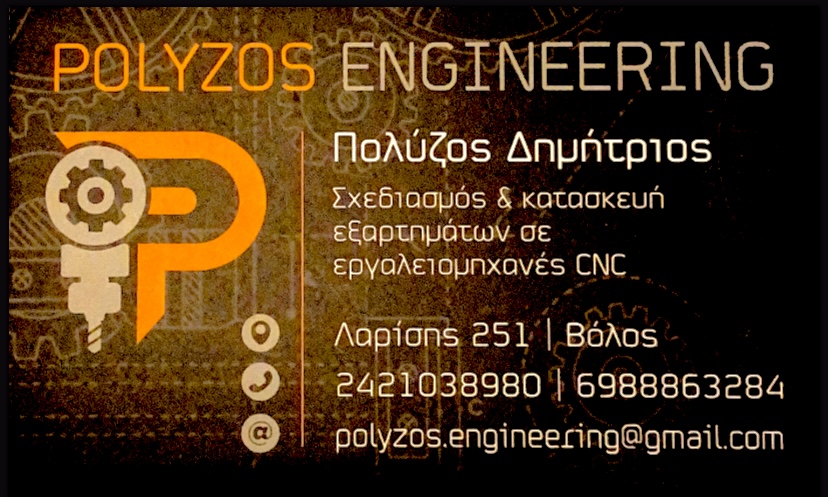

Polyzos Engineering is a leading CNC machine shop that manufactures high-quality parts for local industries. With expertise in creating custom parts from designs or samples, we ensure precision and durability. Our specialization in repairs and reverse engineering allows us to provide tailored solutions for complex mechanical challenges. Committed to innovation and excellence, Polyzos Engineering leverages advanced technology to meet the unique needs of each client. Experience reliable service and exceptional craftsmanship with us. Choose Polyzos Engineering for all your CNC machining requirements.

Founded

1978

Employees

< 5

Certifications

VOLOS

Greece - 38445

The company started in 1990. as a workshop for production and repair of brake cylinders, and today we operate as a company in product development and production of parts made of polymer and metal materials.

Founded

2022

Employees

5 - 10

Certifications

Vrbovec

Croatia - 10340

Founded

1994

Employees

10 - 20

Certifications

Nortorf

Germany - 24589

We are a young, dynamic company and manufacture products made of steel and stainless steel, using separate production areas. We meet the requirements of EN1090 -2 in EXC 2 and ISO 3834 3. We produce welded structures on a production area of around 800m².

Founded

2024

Employees

< 5

Certifications

Bad Aussee

Austria - 8990

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our experience — your added value With over 30 years of tradition, metalution GmbH stands for a reliable machining technology company. Precision, quality and reliability form the basis of the company's philosophy. We are happy to share our experience and know-how with our customers. The company not only has expertise in mass production of parts, but is also an important partner in single-piece production, for example for well-known tool and mold makers. Our customers also include companies from the mechanical and plant engineering sectors. In order to meet these requirements, we rely on highly qualified and independent employees. This makes metalution GmbH flexible and competitive. This niche focus with the right mix of series and single-piece production for machine, mold, device and plant engineering is the basis of our success. In order to ensure this success in the long term, we are always one step ahead of the competition in our work. We encourage our highly qualified employees to work independently so that they can further develop their skills and inspire with quick, flexible and innovative action. “Experience” = the highest level of know-how and sophisticated technology in collaboration with our customers “Flexibility” = project and process management of the highest quality The metalution GmbH plant Usable area: 4120 m2 Production area: 2586 m2 machines 16 milling machines 4 grinding machines 1 laser marking machine 1 waterjet cutting system

Founded

1979

Employees

20 - 50

Certifications

Föritztal

Germany - 96524

The company MWM GmbH & Co. KG, founded in 1998 as a sole proprietorship by the owner and current managing partner, Mr. Michael Wilmes, is a partner of the metalworking industry. MWM sees itself as a system supplier in the field of manufacturing goods and processing components made of aluminum and other non-ferrous metals. We offer our customers full-service solutions in many areas, including procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly. "Qualified employees and modern production machines combined with a high level of commitment and flexibility are the key to success!" The decision to align all business processes according to the rules of DIN ISO 9001-2015 and to carry out continuous improvements secures jobs and a consistently high level of quality, from which you as a customer benefit first and foremost.

Founded

1998

Employees

20 - 50

Certifications

Arnsberg

Germany - 59759

Founded in 1990, Imtec as a leading manufacturer of technical tools, quickly spread to other demanding markets and technologies becoming one of the top companies within mold making industry. It’s labor force is divided in two plants, one for tools up to 3T and the second one for tools up to 25T. In 2017, Imtec established a partnership with IT-MILL which increased even more its capacity with regard to rough milling, deep drillings and mouldbases. Currently, IMTEC provides solutions to its customers in order to ensure the most efficient and durable tool.

Founded

Employees

100 - 200

Certifications

Alcobaça

Portugal - 2460-392

Custom manufacturing In view of our machine tools’ opportunity we can ensure the manufacturing of high-precision parts and the processing of small, medium and large workpieces. With our machines, which are suitable for 2D, 2,5D, 3D and 5D cutting, we are able to produce a wide variety of parts. For our technology we use various 3D-models, which are made available in our CAD/CAM-System by our customers, to increase our efficiency. Prototype Besides wage work, we undertake the initial manufacture of individual prototype products, based on model or drawing, machining optimatization including tools and technology. All machined parts are delivered including 3D coordinate measurement certificate. Device manufacturing Machining or measuring of complex parts may require various devices, therefore our engineers strive to develop the simplest yet most efficient devices. We have gained considerable experience through creating our own devices, which we use in single and series production. Our company undertake the design, production and installation of hydraulic and pneumatic devices as well. Serial production Our machine park is also capable of medium and large series production according to market demands. In series production, generally the most important tasks are the optimization of the machining time and the reduction of the non-productive time. During the processing we pay close attention to process safety and the use of the Poka-yoke principle.

Founded

Employees

5 - 10

Certifications

Kecskemet

Hungary - H-6000

P&M tools construction is a young company that was founded in 2018 by two mechanical engineers with many year od experience. The company was founded to offer the market new conceptual solutions, as well as to contribute to the development of the auto and machine industry. In addition, we deal with tool making, modeling and programing. We offer welding of complex assemblies as well as laser cutting of materials.

Founded

2018

Employees

5 - 10

Certifications

Kragujevac

Serbia - 34000