Find specialized suppliers for gasketing seal foaming on Techpilot. Our platform offers access to suppliers who manufacture high-quality sealing foams for various applications. Benefit from free use of the platform and efficient supplier search.

Component manufacturer for sensors (inductive, capacitive, optical), M8/M12/M23/7.8” connectors, IP67/IP20 IO systems, PLC controls, 3D profile lasers

Founded

Employees

> 1000

Certifications

Oberstenfeld

Germany - 71720

Fa DVM GmbH is a relatively young company in Germany, but has been working for many years already with well-known German and European companies. Our establishment is located in the Swabian Unteraspach (Backnang). Fa DVM GmbH is a competent and reliable partner for the trustful execution of: • QUALITY TESTS • ASSEMBLY • REWORK • ZP / ZFP DESTRUCTIVE TESTING / DESTRUCTIVE TESTING • SUPPLIER MANAGEMENT available. Our wide range of methods and know-how are the basis for the successful and efficient implementation of your (potential) outsourcing projects. DVM company was founded in 2007. DVM company is certified to ISO 9001-2008.

Founded

2007

Employees

20 - 50

Certifications

Aspach

Germany - 71546

CNC milling contract manufacturing We can manufacture plastic, aluminum, brass, copper, steel, stainless steel and tool steel components using a 3-axis CNC milling machine. Key data Minimum component size: 7 x 7 x 7 mm Maximum component size: 450 x 160 x 150 mm Processing in the uncured state (steels) Prototypes individual parts small series Machining strategies Milling Deburring / chamfering Drill Tapping Reduce Rub Thread milling engraving 3D processing Materials plastic Brass aluminum copper steel stainless steel Tool steel

Founded

Employees

Certifications

Spalt

Germany - 91174

The company Flex-Pro d.o.o. was founded in 2008. The main activity of our company is the development, design, manufacture, installation, testing and commissioning of production plants (including complete production lines) in all industrial sectors (metal industry, wood industry, mining, plastics industry). We are also able to manufacture various types of metal and plastic products to customer specifications, including mass production. The main part of the company's business activity is exports to the European Union, in particular to Germany, and the USA. The majority of our exports are industrial plants, which are manufactured, assembled and tested according to customer requirements. It uses high-quality components from well-known manufacturers and proven quality materials manufactured in the European Union. Thanks to our equipment and highly qualified workers, we achieve very high-quality processing and heat treatment of the parts we produce.

Founded

2008

Employees

5 - 10

Certifications

Bijeljina

Bosnia & Herzegovina - 76300

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Automation in Austria — we produce automated and partly by hand products. With our flexible automated production line, we can assemble small assemblies very quickly. Our robots are equipped with a flexible "move & plug" system and are used in numerous assemblies. This enables us to enable automated production for our customers without them having to purchase machines and robots.

Founded

2023

Employees

10 - 20

Certifications

Egg

Austria - 6863

Emmecitecnica, based in Leinì (TO), stands out as a leading company in the field of industrial automation and electrical distribution, boasting over twenty years of experience. Its primary specialization lies in the design and production of electrical panels and wiring, offering innovative solutions suitable for a wide range of applications across various sectors. The driving force behind Emmecitecnica is its team of over 50 highly qualified collaborators, operating within production facilities that span over 3,000 square meters. Equipped with cutting-edge tools such as the Perforex Rittal machining center for cabinetry work, vertical warehouses for efficient material management, and numerous stations for cable cutting and processing, the company ensures high-quality standards. Thanks to steady growth supported by the owner’s investments over the years, Emmecitecnica has solidified its position as a reliable partner for major companies in Italy and abroad. Its ability to certify UL panels for the North American market serves as a distinguishing factor that further strengthens its market position. Emmecitecnica has strong relationships with leading electrical material manufacturers, including Siemens, Abb, Schneider, Eaton, and Rockwell. These collaborations, combined with the expertise of its technical office, allow the company to offer highly qualified consulting services to all its clients.

Founded

Employees

50 - 100

Certifications

Leinì

Italy - 10040

Henkel Modellbau GmbH is a medium-sized company based in Biedenkopf Breidenstein, Hesse. We consistently rely on a highly qualified team and cutting-edge technologies. Our services range from contract manufacturing of a wide variety of parts to the design and manufacture of complex tools.

Founded

1959

Employees

20 - 50

Certifications

Biedenkopf

Germany - 35216

GTS Gate To Steel GmbH is a German company based in Düsseldorf. We are based in the field of mechanical and plant engineering. Our subsidiary is located in Wuxi near Shanghai. We have been in our line of business in China since 2004. We know the market and business inside and out. Our customers are German companies that sell industrial equipment to China. We are not an intermediary! GTS produces itself in its own hall. GTS takes over the production of the local production portion in China for the customers. We manufacture both entire assemblies and individual parts - it only depends on the needs of our customers. Of course we can also take care of the transport to Europe and all related formalities. We stand for: German quality made in China Know-how protection Customary market prices On-time delivery Our highly qualified team in our own assembly hall, together with a proven network of sub-suppliers, form your extended arm in China. Together they realize your projects in your usual German quality. GTS offers you an all-round carefree package tailored to your requirements.

Founded

2015

Employees

10 - 20

Certifications

Düsseldorf, Wuxi

Germany - DE-40223, CN-214185

LCN has a production area of 18,000 m² with a state of the art machinery park and infrastructure. Our dynamic team develops and manufactures premium quality products in close co-operation with our customers at our plant in Guadalajara, Spain (near Madrid) Fine Blanking Conventional Stamping Tube Cold Forming Rotary Swaging Axial Forming High-Performance Grinding Automated Welding Aluminium Die Casting CNC Machining Plastic Overmoulding Complex Assemblies Safety Critical Handbrake Systems Safety Critical Steering Systems Safety Critical Transmission Park Lock Systems

Founded

Employees

200 - 500

Certifications

Guadalajara

Spain - 19004

Good day We are a company from Poland We would like to offer you cooperation in the areas of laser cutting of sheets, 3D laser cutting of profiles and tubes, bending and much more We are engaged in full metal processing: * Laser cutting up to 50mm * 3D laser cutting of pipes and profiles * CNC bending up to 3100mm and thickness 15mm * Welding: TiG, MIG and laser welding We produce both small series and large projects You can save up to 40% of the price including transport. Send the DXF-STP-DWG file to lasernesta@yahoo.com for a quote We also offer the option of shipping by freight forwarding or our own transport to any location in the world. It would be a great pleasure for us to work with your company, we will take care of every detail of your business.

Founded

2017

Employees

50 - 100

Certifications

Wojnicz

Poland - 32830

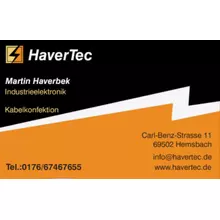

Here is a brief overview of our services: - PCB Assembly (lead free wave soldering and SMD) - soldering - Custom Cable Assembly (round and ribbon cable) with examination - Installation work for example 19 "floors with design and wiring - Cabinet wiring

Founded

2016

Employees

< 5

Certifications

Hemsbach

Germany - 69502

The CIERRE company was founded in 1970 and has grown to around 95 people. CIERRE is a Subconctractor for the Design and Poduction of Electrical, Electronic and Electrical Equipment. Also services such as the supply of materials; management of the customer’s Material Deposit at us. Links with the Customer’s ERP software. Cierre has a Commercial office, Purchase office; Technical office; R&D office; CIERRE performs Design and Construction of: 1---elektronic, electrical, electrical, equipment (apparatus); 2---wiring of traditional and SMT electronic boards with lines of 30.000 components hour. 3---cables; wiring of single cable; multi-pole cable; SPEVIAL; RESINATED; MOLMED cables; according to customer’s design; signal cables on board Pre-Shaped, with a high number of conductors and then TESTED; power cables up to 240mmq; cables from 0,12 mmq to 180 mmq; flat cables; 4---assembly of POWER electronics; on panels; in cabinet; groups; sub-groups; power semi-finished products; UPS units; Inverters; Power supplies; converters. 5---all about customer specifications and requests; even RHOS. 6---CIERRE is a TUV Certified Sub-contractor ISO 9001; ISO 14000; UL cables.

Founded

1970

Employees

50 - 100

Certifications

Berra

Italy - 44033

Our company offers metalworking services. A very wide and complex machine park offers you the opportunity to process various inquiries. We have finished parts and assemblies from a single source, even if we have to procure them elsewhere from our partners near or far from Poland.

Founded

2008

Employees

20 - 50

Certifications

Krepa/Zielona Góra

Poland - 66-001

Kolada Feinwerktechnik is a modern, responsible family company with a wide range of services and a good working atmosphere. Since 1998 we have been working with competence and responsibility not only as a supplier of turned and milled parts but our tasks go far beyond the mere delivery of technical components. Due to the constantly growing machinery and the steadily increasing order volume, the move to our new production and administration building in Kaltenkirchen took place in 2015. On an area of 900 m², we manufacture high-quality precision parts for the aviation, medical technology and automotive industries with our experienced and qualified employees. Our company has extensive experience in processing a wide variety of materials and a wide range of manufacturing options. Our state-of-the-art machinery and our CAD / CAM systems ensure the best conditions for the production of customized and tailor-made parts. In our component assembly we assemble precision parts made of different materials into ready-to-install components. We have been working with competent partners for additional surface treatments for years. The satisfaction of our customers and adherence to delivery dates are our most important corporate goals. Qualified and competent advice round off our service concept perfectly.

Founded

1998

Employees

10 - 20

Certifications

Kaltenkirchen

Germany - 24568

Our service options range from simple search work, to screen and pad printing, to complex assembly of automotive assemblies. Manual assembly devices for small quantities and prototypes or the use of system-controlled special machines, we develop ice-specific to be able to connect seamlessly to your production.

Founded

Employees

< 5

Certifications

Hagen

Germany - 58119

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Soldering technology & heat treatments Vacuum soldering, inert gas soldering, induction soldering Annealing under vacuum and protective gas Manufacture of complete solder assemblies

Founded

1981

Employees

100 - 200

Certifications

Fröndenberg

Germany - 58730

Familiar like the department next door. Toll manufacturing with in-house manufacturing. Thanks to our close network of local partners, we are able to offer a far-reaching technological spectrum. We take over your labour-intensive assembly tasks and test systems individually. Excerpt of our services: 1 Manufacturing by machining, bending/edging, laser cutting, welding 2 Assembly of components, assemblies, mechatronic systems 3 Process simplification through sophisticated procedures, simplification of the supply chain law, reduction of the throughput time from the idea to BANF.

Founded

Employees

< 5

Certifications

Leonberg

Germany - 71229

We are a production service company. We take individual steps in production, such as quality control, packaging, repackaging, or the assembly and assembly of your assemblies or products from. If required, we also organize the complete physical implementation of your product, from the procurement of individual parts, through production and warehousing, to shipping. We support you in the production outsourcing. In addition to pre-sorting and set formation, we also undertake the assembly and assembly of your products. From screwing to bonding and the fitting of fittings, from filling with liquids and bulk solids, to functional tests and proper packaging, we undertake a variety of activities. If necessary, we analyze your production processes and identify areas in which we can generate maximum added value.

Founded

2012

Employees

10 - 20

Certifications

Ehingen

Germany - 89584

Founded

2016

Employees

10 - 20

Certifications

Harpstedt

Germany - 27243

Steiner Elektronik Ltd is a reliable and recognized partner for the production of circuit boards and electronic components. Services portfolio: • Delivery of circuit boards • SMD/THT assembly • Cable assembly • Assembly of complete devices • Test — AOI, functional and in-circuit test • Quality assurance — ISO 9001:2015 and ISO 14001:2015 • Selective soldering • coating • ESD protection

Founded

1969

Employees

100 - 200

Certifications

Ruse

Bulgaria - 7018

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge